Top 5 Infotainment Screens for Your Car in 2022

By:Admin

The infotainment screen is equipped with a high-definition display, offering crisp and clear visuals for a truly immersive experience. Its touch-sensitive interface allows for effortless navigation through various menus and options, while its intuitive design ensures that users can easily access the features they need without any hassle. The screen also supports voice recognition technology, enabling drivers to control various functions and settings with simple voice commands, further enhancing safety and convenience on the road.

One of the standout features of the infotainment screen is its connectivity options, which include Bluetooth, Wi-Fi, and smartphone integration. This allows users to seamlessly connect their mobile devices to the screen, enabling them to access their favorite apps, music, and other media directly from the vehicle's dashboard. Not only does this provide a more convenient and enjoyable driving experience, but it also helps to minimize distractions by keeping drivers focused on the road.

In addition to entertainment features, the infotainment screen also offers comprehensive navigation capabilities, including real-time traffic updates, turn-by-turn directions, and points of interest. This ensures that drivers can easily find their way to their destination while staying informed about current road conditions, helping to reduce travel time and improve overall driving efficiency.

Furthermore, the infotainment screen provides access to a wide range of vehicle information, such as fuel economy, tire pressure, and maintenance alerts. This allows drivers to stay informed about the health and performance of their vehicle, empowering them to take proactive measures to ensure its longevity and reliability.

Car manufacturer X has always been at the forefront of automotive innovation, consistently pushing the boundaries of technology to deliver an exceptional driving experience for consumers. With the introduction of the new infotainment screen, the company continues to demonstrate its commitment to integrating advanced features and functionality into its vehicles, setting a new standard for in-car entertainment and connectivity.

The infotainment screen is the latest addition to the company's lineup of cutting-edge technologies, which also includes advanced safety features, autonomous driving capabilities, and electrified powertrains. By incorporating these technologies into its vehicles, Car manufacturer X is leading the charge towards a more connected, efficient, and sustainable future for the automotive industry.

As a company, Car manufacturer X has a rich history of innovation and excellence, with a focus on delivering high-quality vehicles that embody the perfect balance of performance, comfort, and technology. Its commitment to customer satisfaction and continuous improvement has earned it a reputation as a leader in the automotive industry, with a loyal customer base and a strong presence in markets around the world.

With the introduction of the new infotainment screen, Car manufacturer X has once again raised the bar for in-car technology, setting a new standard for what consumers can expect from their vehicles. As the automotive industry continues to evolve, Car manufacturer X remains dedicated to driving innovation and shaping the future of mobility, one groundbreaking technology at a time.

Company News & Blog

Enhance Your Manufacturing Process with a High-Capacity Powder Coat Oven

Large Powder Coat Oven Enhances Productivity and Efficiency in the Manufacturing IndustryIn the ever-evolving manufacturing industry, companies are constantly on the lookout for cutting-edge technology and equipment to enhance their productivity and efficiency. One such innovation that has proven to be a game-changer is the Large Powder Coat Oven, a revolutionary piece of equipment that has revolutionized the powder coating process.Powder coating is a widely used finishing technique in the manufacturing industry as it provides a durable, high-quality finish to various metal products. It involves the application of a dry powder to a surface, which is then cured under heat to form a protective and visually appealing coating. While this technique offers numerous advantages over traditional painting methods, it requires an efficient curing process to achieve optimal results, and that's where the Large Powder Coat Oven comes into play.Manufactured by a renowned industry player, the Large Powder Coat Oven is designed to provide manufacturers with a streamlined and efficient curing process. With its ample interior space and advanced heating technology, this oven can accommodate a considerable quantity of coated products, allowing for increased throughput and reduced processing time. Furthermore, its precise temperature control system ensures uniform heating throughout the curing process, resulting in consistent and high-quality finishes.One key feature that sets this Large Powder Coat Oven apart is its heating system. Equipped with state-of-the-art infrared heating elements, it delivers rapid and efficient heat transfer to the coated products, significantly reducing curing time. This not only enhances productivity and reduces energy consumption but also enables manufacturers to meet tight production deadlines, ultimately improving customer satisfaction.Moreover, the Large Powder Coat Oven incorporates an advanced control panel that offers user-friendly operation and customization options. Manufacturers can easily set and monitor curing parameters such as time, temperature, and airflow, allowing for precise control over the curing process. This level of customization ensures that each product receives the ideal curing conditions, resulting in excellent adhesion, hardness, and durability of the coating.The company behind this groundbreaking powder coat oven is a well-established industry leader in manufacturing equipment. With years of experience and expertise, they have consistently delivered innovative solutions to cater to the evolving needs of the manufacturing industry. Their commitment to excellence is mirrored in the meticulous design and construction of the Large Powder Coat Oven, as well as their dedication to ensuring customer satisfaction.By investing in this cutting-edge oven, manufacturers can reap multiple benefits. The increased throughput and reduced processing time provided by the Large Powder Coat Oven directly translate into enhanced productivity and efficiency, allowing companies to meet higher production demands and maximize profitability. Additionally, the oven's superior heating technology and precise control features guarantee consistent and high-quality finishes, which are crucial for maintaining a competitive edge in the market.Furthermore, the Large Powder Coat Oven contributes to environmental sustainability. Traditional painting methods often involve hazardous chemicals and emit harmful volatile organic compounds (VOCs) into the atmosphere. In contrast, powder coating is an eco-friendly alternative as it produces no VOCs and generates minimal waste. The energy efficiency of the Large Powder Coat Oven further minimizes the environmental impact, making it a responsible choice for manufacturers committed to sustainability.In conclusion, the introduction of the Large Powder Coat Oven has revolutionized the powder coating process in the manufacturing industry. Its advanced heating system, precise control features, and user-friendly operation combine to enhance productivity, efficiency, and product quality. By investing in this cutting-edge equipment, manufacturers can streamline their curing process, meet higher production demands, and contribute to a more sustainable future. The Large Powder Coat Oven is undoubtedly a game-changer in the manufacturing industry, set to shape the future of powder coating technology.

High-quality Spray Booths for Your Olympic Business Needs

Olympic Spray Booths, a leading manufacturer of state-of-the-art industrial spray booths and finishing systems, has been making waves in the industry with its innovative and high-quality products. With a commitment to excellence and a focus on customer satisfaction, the company has carved a niche for itself in the highly competitive market.Established in {} years ago, Olympic Spray Booths has been at the forefront of technological advancements in the spray booth industry. The company's success can be attributed to its unwavering dedication to producing top-of-the-line products that meet the evolving needs of its customers. From automotive to aerospace, Olympic Spray Booths has been a trusted partner for businesses across various sectors.One of the key factors that set Olympic Spray Booths apart from its competitors is its relentless pursuit of innovation. The company invests heavily in research and development to stay ahead of the curve and deliver cutting-edge solutions to its clients. The result is a diverse range of spray booths and finishing systems that are not only efficient and reliable but also environmentally friendly.Olympic Spray Booths takes pride in its ability to customize its products based on the specific requirements of its customers. Whether it's a small, family-owned body shop or a large-scale manufacturing facility, the company has the expertise and resources to design and build spray booths that seamlessly integrate into its clients' operations. This personalized approach has earned Olympic Spray Booths a loyal customer base that continues to grow with each passing year.In addition to its commitment to quality and innovation, Olympic Spray Booths places a strong emphasis on customer service. The company understands that purchasing a spray booth is a significant investment for its clients, and it strives to provide the highest level of support from the initial consultation to post-installation maintenance. This dedication to customer satisfaction has earned Olympic Spray Booths a stellar reputation in the industry and has contributed to its continued success.With a focus on sustainability, Olympic Spray Booths has also made significant strides in developing eco-friendly solutions that minimize the environmental impact of its products. The company's spray booths are designed to maximize energy efficiency and reduce waste, aligning with its commitment to responsible manufacturing practices. By prioritizing sustainability, Olympic Spray Booths not only benefits the environment but also helps its clients achieve their own sustainability goals.Looking ahead, Olympic Spray Booths is poised for continued growth and success. The company remains dedicated to pushing the boundaries of innovation and providing unmatched value to its customers. With a team of experienced professionals and a clear vision for the future, Olympic Spray Booths is well-positioned to remain a leading force in the spray booth industry for years to come.In conclusion, Olympic Spray Booths has established itself as a trusted name in the spray booth industry, thanks to its unwavering commitment to excellence, innovation, and customer satisfaction. With a focus on quality, customization, sustainability, and superior customer service, the company continues to set the standard for spray booth manufacturers. As it looks to the future, Olympic Spray Booths is poised to build on its success and solidify its position as a market leader.

High-Quality 6x6 Powder Coat Oven for Efficient Coating Processes

In recent news, a leading industrial equipment manufacturing company has announced the launch of their latest product, the 6x6 Powder Coat Oven. This innovative new oven is designed to provide high-quality powder coating for a wide range of industrial applications, and is set to revolutionize the powder coating industry with its state-of-the-art features and capabilities.The 6x6 Powder Coat Oven is the latest addition to the company's extensive line of industrial ovens and equipment, and is set to further solidify the company's position as a leader in the manufacturing and supply of industrial machinery. With its advanced design and cutting-edge technology, the new oven is expected to set new standards for powder coating efficiency and productivity.The 6x6 Powder Coat Oven is built with a heavy-duty construction, and is designed to withstand the rigors of continuous use in industrial environments. Its spacious 6x6 interior provides ample room for large parts and components, making it ideal for a wide range of powder coating applications. The oven features a precision temperature control system, ensuring accurate and consistent curing of powder coatings for a flawless finish every time.This new addition to the company's product line is a testament to their commitment to innovation and excellence in the industrial equipment industry. The 6x6 Powder Coat Oven is a result of extensive research and development, and is a testament to the company's dedication to meeting the evolving needs of their customers.With the launch of the 6x6 Powder Coat Oven, the company aims to provide their customers with a comprehensive solution for their powder coating needs. The oven is designed to streamline the powder coating process, reducing production time and costs while ensuring the highest quality finish for industrial components and parts.The company's dedication to customer satisfaction and their strong reputation for delivering reliable and high-performing industrial equipment make them a trusted partner for businesses in need of quality industrial ovens and machinery. With the addition of the 6x6 Powder Coat Oven to their product line, the company is poised to further strengthen their position as a leading supplier of industrial equipment.The innovative design and advanced features of the 6x6 Powder Coat Oven are a reflection of the company's commitment to pushing the boundaries of what is possible in the industrial equipment industry. With a focus on quality, reliability, and performance, the company continues to set the standard for industrial ovens and machinery.The launch of the 6x6 Powder Coat Oven is an exciting development for the industrial equipment industry, and is set to bring significant benefits to businesses in need of high-quality powder coating solutions. With its advanced features, precision engineering, and robust construction, the oven is a testament to the company's dedication to driving progress and innovation in the industrial equipment sector.In conclusion, the introduction of the 6x6 Powder Coat Oven marks a significant milestone for the company, and reinforces their position as a leader in the industrial equipment industry. With its advanced features and capabilities, the new oven is set to provide businesses with a reliable and efficient solution for their powder coating needs, further solidifying the company's reputation for delivering high-quality industrial machinery and equipment.

Discover the Benefits of an Efficient Oil Spray Booth for Industrial Operations

Title: Cutting-Edge Oil Spray Booth Revolutionizes Industrial Painting ProcessesIntroduction:In today's rapidly evolving industrial landscape, companies across various sectors are continually seeking ways to streamline and enhance their production processes. Addressing this need for efficiency and innovation, an industry-leading company has introduced its groundbreaking Oil Spray Booth, revolutionizing the way industrial painting is conducted. This cutting-edge technology promises to optimize paint application, reduce waste, and improve overall operational efficiency, making it a game-changer for manufacturing facilities worldwide.Paragraph 1:The newly developed Oil Spray Booth integrates state-of-the-art features, delivering unparalleled precision and control over the painting process. Equipped with advanced automation capabilities, the booth allows for precise adjustments of spray patterns, ensuring optimal coating thickness and even application. This breakthrough technology eliminates the challenges associated with manual painting techniques, providing a consistent and flawless finish on a wide range of surfaces.Paragraph 2:In addition to superior control, the Oil Spray Booth offers remarkable efficiency improvements. With its optimized airflow design, the booth effectively captures overspray, reducing waste and minimizing environmental impact. By preventing excessive paint usage, manufacturers can significantly cut down on material costs, ultimately boosting their bottom line. Moreover, the booth's automated cleaning system simplifies maintenance, reducing downtime and enabling uninterrupted production cycles.Paragraph 3:By adopting this innovative solution, manufacturing facilities can enhance workplace safety standards. The Oil Spray Booth's advanced filtration system efficiently captures hazardous particles, preventing their release into the environment. This feature not only ensures compliance with strict regulatory standards but also safeguards workers' health by reducing exposure to harmful substances. As a result, companies using this cutting-edge technology can create a safer and healthier working environment for their employees.Paragraph 4:The Oil Spray Booth's remarkable capabilities extend beyond the industrial painting realm, making it an incredibly versatile solution. Whether in the automotive, aerospace, woodworking, or construction industries, this technology provides a consistent and precise finish on various substrates. Its adaptability caters to the unique requirements of diverse industries, including both small-scale production facilities and large-scale manufacturing plants.Paragraph 5:To meet the evolving needs of their clients, the company behind this innovative solution has continuously invested in research and development. It has collaborated closely with industry experts to ensure their Oil Spray Booth remains at the cutting edge of technology, incorporating feedback and insights from manufacturers across different sectors. The result is a solution that addresses industry challenges, enables process optimization, and sets new benchmarks for quality and efficiency.Conclusion:In an era where optimization and efficiency are paramount, the introduction of the Oil Spray Booth marks a significant milestone in industrial painting. This innovative technology brings unparalleled control, efficiency, and safety to the painting process, catering to diverse industries' specific needs. By embracing this cutting-edge solution, manufacturers can seamlessly integrate an advanced and sustainable approach to painting into their operations, resulting in improved quality, reduced wastage, and increased profitability.

Custom 14,000 GVW Race Trailer with Removable Bolt-On Toolboxes and Under-Deck Water Storage

In the world of racing, the need to transport equipment and vehicles from one location to another is of utmost importance. That's where the custom-built 2021 20ft x102 14,000GVW race trailer comes in.This trailer is designed to provide the necessary support, space, and safety to transport two racing rigs and essential equipment. It features a rectangular tubing frame, bolt-on toolboxes that can be removed for ramps, and 80 gallons of fresh water mounted under the deck. The locking gal gas can ensures that the fuel is always secure during transportation.What's more, this trailer is not just functional, but it's also aesthetically appealing. It boasts a powder coating finish that gives it a sleek look while also protecting it from rusting and corrosion. The powder coating process creates a hard, durable, and resistant finish that will last for a long time, saving you money on maintenance and repairs.If you are looking for a trailer that is durable, functional, and looks great, this custom-built 20ft x102 race trailer is an excellent choice. The powder coating finish ensures that it can withstand tough conditions, including harsh weather and long hours on the road.Finally, if you're interested in powder coating, you may also want to consider a 20ft powder coating oven, which is a device used to apply a coat of powder to a material or item. It's a great investment for businesses that require custom powder coating for their products. By owning this oven, you can save money in the long run and increase your business's productivity.In conclusion, the custom-built 2021 20ft x102 race trailer is a great investment for race teams and businesses that require reliable and safe transportation. The powder coating finish ensures that it looks great while also providing resistance against rust and other forms of damage. If you're interested in powder coating as well, consider investing in a 20ft powder coating oven for your business.

Top Benefits of Using a Slat Conveyor in Your Business Operations

{Company Name}, a leading provider of material handling solutions, has recently introduced a new and innovative slat conveyor to its product line. The new slat conveyor is designed to offer a reliable and efficient solution for moving heavy and bulky items in a variety of industries.The slat conveyor is a versatile and durable material handling system that is ideal for applications such as manufacturing, distribution, and logistics. It is capable of handling a wide range of products, including boxes, totes, and other heavy items, making it an ideal solution for businesses looking to improve their material handling processes.One of the key features of the new slat conveyor is its modular design, which allows for easy customization and integration into existing conveyor systems. This modular design also makes it easy to add or remove sections of the conveyor as needed, giving businesses the flexibility to adapt to changing production or distribution requirements.In addition to its modular design, the slat conveyor also features a robust construction that is capable of withstanding heavy loads and harsh operating conditions. This makes it an ideal solution for businesses with demanding material handling requirements, such as those in the automotive, manufacturing, and aerospace industries.The slat conveyor is also equipped with a range of safety features to ensure safe and reliable operation. These features include guarding, emergency stops, and safety interlocks, all of which are designed to minimize the risk of accidents and injuries in the workplace.In addition to its superior performance and safety features, the slat conveyor also offers a number of operational benefits. Its low maintenance requirements and energy-efficient design help to reduce operating costs, while its smooth and quiet operation ensures minimal disruption to the work environment."We are excited to introduce our new slat conveyor to the market," said a spokesperson for {Company Name}. "With its superior performance, durability, and versatility, we believe that it will be a valuable addition to our customers' material handling operations."{Company Name} has established itself as a trusted provider of material handling solutions, with a strong reputation for delivering high-quality products and excellent customer service. The introduction of the new slat conveyor further solidifies the company's commitment to meeting the evolving needs of its customers and providing innovative solutions for their material handling challenges.The new slat conveyor is now available for purchase and can be customized to meet the specific requirements of different industries and applications. {Company Name} also offers a range of support services, including installation, training, and ongoing maintenance, to ensure that customers get the most out of their material handling investment.With its advanced design, reliable performance, and operational benefits, the new slat conveyor from {Company Name} is set to make a significant impact on the material handling industry. Businesses looking to improve their efficiency, productivity, and safety in material handling can now turn to {Company Name} for a trusted solution.

High-Quality Spray Booth Extractor Fan for Efficient Ventilation

Founded in [year], [Company Name] has established itself as a leading manufacturer of industrial ventilation and extraction systems. With a focus on providing high-quality and innovative solutions for a wide range of industries, the company has built a strong reputation for reliability and performance.In line with its commitment to delivering cutting-edge products, [Company Name] is proud to announce the launch of its latest innovation – the [Model Name] Spray Booth Extractor Fan. Designed to meet the demanding needs of paint spray booth environments, this advanced extraction system sets new standards for efficiency and reliability.The [Model Name] Spray Booth Extractor Fan is the result of [Company Name]'s extensive research and development efforts, aimed at addressing the challenges faced by businesses operating in paint spray booth applications. With a powerful and energy-efficient motor, this extractor fan is capable of effectively capturing and removing paint overspray, fumes, and other airborne contaminants from the working environment.One of the key features of the [Model Name] Spray Booth Extractor Fan is its intelligent airflow management system, which optimizes the performance of the system while minimizing energy consumption. This not only reduces operational costs for businesses but also enhances the overall sustainability of the paint spray booth facilities. Additionally, the system is designed to provide a balanced and consistent airflow, ensuring thorough and uniform extraction throughout the booth.Furthermore, the [Model Name] Spray Booth Extractor Fan is equipped with a state-of-the-art filtration system, which effectively captures and contains paint particles and other hazardous substances. This ensures a cleaner and healthier working environment for employees, while also helping businesses comply with strict environmental and safety regulations.As with all [Company Name] products, the [Model Name] Spray Booth Extractor Fan is built to last, with a robust and durable construction that can withstand the rigors of industrial environments. The fan is also designed for easy maintenance, with accessible components and a user-friendly interface, minimizing downtime and ensuring continuous operation.“We are thrilled to introduce the [Model Name] Spray Booth Extractor Fan to the market,” said [Spokesperson Name], [Position] at [Company Name]. “This product is a testament to our ongoing commitment to innovation and excellence, and we are confident that it will set new industry standards for performance and reliability in paint spray booth applications.”In addition to its exceptional performance, the [Model Name] Spray Booth Extractor Fan is backed by [Company Name]'s renowned customer support and after-sales service. With a global network of service centers and a team of skilled technicians, businesses can rely on [Company Name] for ongoing support and maintenance of their extraction systems.As businesses continue to prioritize the safety and well-being of their employees, the demand for advanced extraction solutions, such as the [Model Name] Spray Booth Extractor Fan, is expected to rise. By offering a combination of cutting-edge technology, industry expertise, and reliable support, [Company Name] is well-positioned to meet this growing demand and provide businesses with the tools they need to create safe and efficient work environments.The [Model Name] Spray Booth Extractor Fan is now available for purchase through [Company Name]'s authorized distributors and partners. To learn more about this innovative product and explore the full range of industrial ventilation and extraction solutions offered by [Company Name], visit their website or contact their sales team for more information.

Innovative System for Waste Water Treatment: A Sustainable Solution for Cleaner Water

UF System for Waste Water Treatment Introduced by Leading Environmental Technology Company{Company} is proud to announce the launch of their state-of-the-art UF system for waste water treatment. This innovative technology is designed to provide sustainable and efficient solutions for water and wastewater treatment in a wide range of industries.The UF system utilizes ultrafiltration membranes to effectively remove suspended solids, bacteria, viruses, and other pathogens from water. This advanced filtration process ensures that the treated water meets the required quality standards for discharge or reuse, while also minimizing the environmental impact of industrial and municipal wastewater.{Company} has a long-standing reputation as a leading provider of environmental technology solutions, with a strong focus on developing sustainable and cost-effective systems for water and wastewater treatment. The introduction of the UF system further enhances their commitment to delivering cutting-edge solutions that address the growing challenges of water scarcity and water pollution.One of the key advantages of the UF system is its ability to achieve high levels of water recovery, minimizing the need for fresh water intake and reducing the volume of wastewater generated. This not only helps in conserving natural resources but also significantly lowers operating costs for businesses and municipalities.The UF system is also designed to be modular and scalable, allowing for easy integration into existing water treatment facilities or as a standalone treatment solution for smaller operations. This flexibility makes it an ideal choice for a wide range of applications, including industrial process water treatment, municipal wastewater treatment, and decentralized water and wastewater treatment for remote or rural communities.Furthermore, the UF system is engineered for reliable and continuous operation, with automated controls and monitoring systems that ensure optimal performance and minimal downtime. This is crucial for industries and municipalities that depend on consistent and reliable water treatment processes to meet regulatory requirements and maintain operational efficiency.In addition to the UF system itself, {Company} also offers comprehensive support services, including technical assistance, maintenance, and spare parts supply. This ensures that customers can rely on the continued performance and longevity of their UF systems, with the peace of mind that comes from partnering with a trusted and experienced provider.The launch of the UF system for waste water treatment further strengthens {Company}'s position as a leading innovator in the field of environmental technology. With a strong focus on sustainability, efficiency, and reliability, {Company} continues to develop and deliver solutions that meet the evolving needs of industries and communities worldwide.The UF system for waste water treatment is now available for purchase and installation, and {Company} welcomes inquiries from businesses, municipalities, and organizations looking to implement advanced water treatment solutions. For more information about the UF system and other environmental technology solutions offered by {Company}, please visit their website or contact their sales team directly.About {Company}:{Company} is a global provider of environmental technology solutions, specializing in water and wastewater treatment systems for industrial, municipal, and commercial applications. With a commitment to sustainability and innovation, {Company} develops cutting-edge technologies that address the challenges of water scarcity, water pollution, and environmental protection. Their comprehensive range of products and services includes filtration systems, disinfection systems, membrane systems, and advanced control and monitoring solutions. With a strong focus on customer satisfaction and environmental stewardship, {Company} is dedicated to delivering reliable and cost-effective solutions that meet the highest standards of performance and quality.

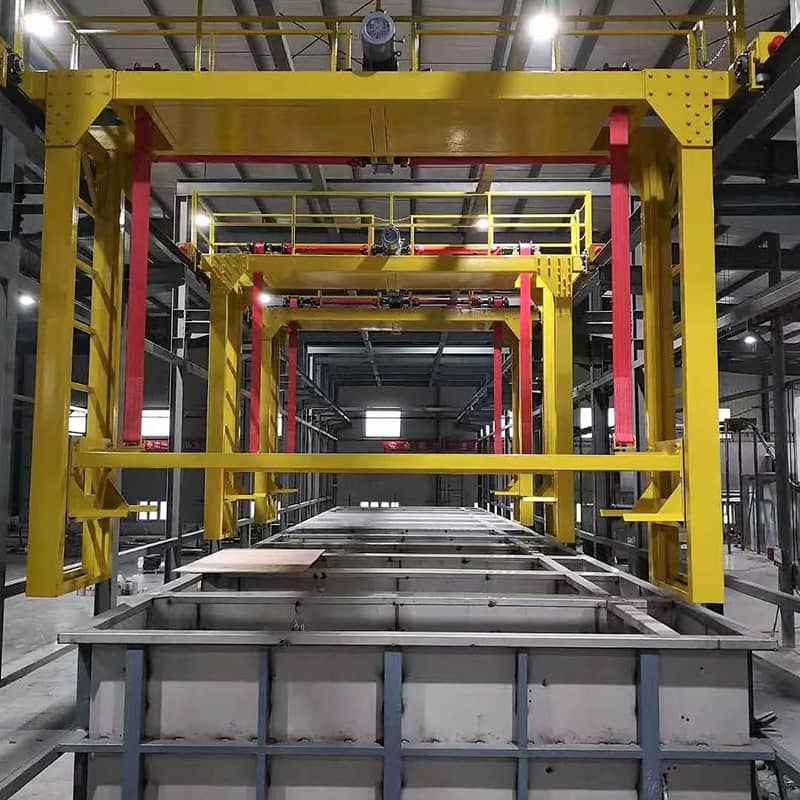

Revolutionary Automated Painting Line That Streamlines Manufacturing Processes

Title: Streamlining Production Processes: Introducing an Innovative Automatic Painting LineIntroduction:In today's rapidly evolving industrial landscape, companies across various sectors are constantly seeking out advanced technological solutions to enhance their production processes. Marking a significant milestone in the industry, an innovative Automatic Painting Line has been recently launched by an industry-leading manufacturer. This state-of-the-art solution presents a paradigm shift in efficiency, quality, and sustainability. This article explores the salient features of this transformative Automatic Painting Line, revolutionizing conventional painting methods.Automating the Painting Process:The newly developed Automatic Painting Line integrates cutting-edge robotic technology to streamline the traditionally labor-intensive and time-consuming painting process. This high-performing system comprises a network of automated robots working in synchronization, thereby drastically improving efficiency and productivity. By minimizing human intervention, potential errors and inconsistencies in the final product are significantly reduced, ensuring superior quality and precision.Quality Assurance and Customization:Implementing advanced sensors and precision controls, the Automatic Painting Line guarantees consistent application of paint, resulting in high-quality finished products. The technology allows for precise regulation of the amount and thickness of paint applied, ensuring uniformity across the production line. This exceptional level of accuracy leads to enhanced product aesthetics and customer satisfaction.Furthermore, the system's programmable settings enable customization options, allowing manufacturers to adjust paint colors, finishes, and textures according to customer requirements. This flexibility provides companies with a competitive edge by catering to diverse market demands while maintaining production efficiency.Optimizing Resource Management:Extensively equipped with smart automation features, the Automatic Painting Line efficiently manages resources, contributing to increased sustainability. Advanced algorithms analyze production data in real-time, optimizing paint consumption and reducing waste. Furthermore, the system incorporates a closed-loop system that recycles excess paint, minimizing environmental impact.Improved Worker Safety:One of the most notable advantages of this innovative system lies in its prioritization of worker safety. By minimizing human involvement in potentially hazardous tasks, the Automatic Painting Line significantly reduces the risk of accidents and exposure to harmful chemicals. This technology ensures a safer working environment for employees while also complying with strict health and safety regulations.Cost Reduction and Time Efficiency:The adoption of the Automatic Painting Line brings about significant cost savings for manufacturers. By dramatically reducing labor costs and minimizing material wastage, companies can enhance their profitability and allocate resources elsewhere within their operations. Additionally, the system's high-speed production capabilities contribute to shorter turnaround times, enabling manufacturers to meet demanding market deadlines and customer expectations.Integration and Compatibility:The Automatic Painting Line is fully compatible with existing industrial systems, making it a versatile solution for manufacturers of various sizes and industries. Companies can seamlessly integrate this advanced automation technology into their production facilities without the need for extensive modifications or disruptions.Conclusion:In conclusion, the introduction of an innovative Automatic Painting Line offers the manufacturing industry a groundbreaking solution to enhance efficiency, quality, and sustainability. By leveraging cutting-edge robotics and automation technology, this revolutionary system optimizes resource management, ensures precision, improves worker safety, and reduces costs. With this transformative technological advancement, manufacturers can streamline their painting processes, meet evolving market demands, and stay at the forefront of modern industry practices.

Effective Sprayer Nozzle for Cleaning and Sanitizing

Spray Ball Nozzle, an innovative product designed for efficient and thorough cleaning of tanks and vessels, has been making waves in the industrial cleaning industry. With its unique design and exceptional performance, it has become the go-to solution for companies looking to maintain cleanliness and hygiene in their facilities.The Spray Ball Nozzle is manufactured by a leading company that specializes in providing high-quality cleaning solutions for various industries. With decades of experience and expertise in the field, the company has established itself as a reliable and trusted partner for businesses looking to improve their cleaning processes.One of the key features of the Spray Ball Nozzle is its ability to deliver a consistent and powerful spray pattern, ensuring thorough coverage of all surfaces within the tank or vessel. This is achieved through the use of precision-engineered nozzles that are strategically positioned to maximize cleaning effectiveness. As a result, companies can achieve superior cleanliness with minimal time and effort, ultimately improving their operational efficiency.In addition to its exceptional performance, the Spray Ball Nozzle is also designed for ease of installation and maintenance. Its simple and robust design allows for quick and hassle-free setup, reducing downtime and increasing overall productivity. Furthermore, the materials used in its construction are highly durable and resistant to corrosion, ensuring a long service life and minimal need for replacement or repairs.The company behind the Spray Ball Nozzle takes pride in its commitment to quality and customer satisfaction. They adhere to strict manufacturing standards and conduct thorough testing to ensure that their products meet the highest performance and reliability criteria. This dedication to excellence has earned them a loyal customer base and a reputation for delivering top-notch cleaning solutions.With a focus on innovation and continuous improvement, the company is constantly refining its products to meet the evolving needs of the industry. This includes investing in research and development to explore new materials, designs, and technologies that can further enhance the performance and efficiency of their cleaning solutions. As a result, customers can expect cutting-edge products that deliver exceptional results and contribute to their overall success.The Spray Ball Nozzle has been widely adopted across a range of industries, including food and beverage, pharmaceuticals, chemicals, and manufacturing. Its versatility and adaptability make it suitable for a wide variety of tank and vessel cleaning applications, ensuring that companies can benefit from its superior cleaning capabilities regardless of their specific requirements.In conclusion, the Spray Ball Nozzle is a game-changer in the industrial cleaning industry, providing companies with a reliable and efficient solution for maintaining cleanliness and hygiene in their facilities. With its exceptional performance, ease of installation and maintenance, and a commitment to quality, it has become the go-to choice for businesses looking to elevate their cleaning processes. As the company continues to push the boundaries of innovation, customers can look forward to even more impressive cleaning solutions that will help them stay ahead in their respective industries.