The Ultimate Guide to Powder Coating: Everything You Need to Know

By:Admin

{Company} is proud to announce the latest addition to its line of innovative products – Manual Powder Coating. With the introduction of this new technology, {Company} continues to solidify its position as a leader in the powder coating industry.

Manual Powder Coating is a versatile and efficient solution for applying a durable and uniform finish to a wide range of surfaces. It offers several advantages over traditional liquid painting, including better durability, improved appearance, and enhanced resistance to chipping, scratching, and fading. This makes it an ideal choice for a variety of applications, including automotive parts, metal furniture, machinery, and much more.

{Company} has developed a comprehensive range of Manual Powder Coating equipment and supplies, designed to meet the specific needs of its customers. This includes a selection of powder coating guns, control units, and accessories, as well as a variety of powders in different colors and finishes. Additionally, {Company} offers expert technical support and training to ensure that customers can achieve the best results with their Manual Powder Coating systems.

One of the key advantages of Manual Powder Coating is its environmental friendliness. Unlike liquid paint, powder coating does not contain harmful solvents or volatile organic compounds (VOCs), making it a more sustainable and eco-friendly option. This has become increasingly important as businesses and consumers alike seek out greener and more responsible alternatives to traditional coating methods.

With the introduction of Manual Powder Coating, {Company} has once again demonstrated its commitment to innovation and excellence in the field of surface finishing. The company has a long-standing reputation for delivering high-quality products and exceptional customer service, and this latest offering is no exception.

In addition to its Manual Powder Coating systems, {Company} offers a wide range of other products and services to support its customers' coating needs. This includes automated powder coating systems, liquid painting equipment, surface preparation solutions, and more. {Company} prides itself on being a one-stop shop for all surface finishing requirements, providing everything from equipment and supplies to technical expertise and support.

{Company} has established itself as a trusted partner for businesses across a diverse range of industries, from automotive and aerospace to furniture and architecture. With its broad expertise and dedication to customer satisfaction, {Company} has earned a strong and loyal customer base, both domestically and internationally.

As the demand for high-quality and sustainable surface finishing solutions continues to grow, {Company} is well-positioned to meet the needs of its customers with its Manual Powder Coating technology. The company remains committed to pushing the boundaries of innovation and delivering cutting-edge solutions that deliver superior results.

For more information about Manual Powder Coating and other products and services offered by {Company}, please visit their website or contact their customer service team.

Company News & Blog

Discover the Benefits of Gunmetal Spray Paint for Your DIY Projects

Gunmetal Spray Paint: Boosting Style and Durability for All Your DIY Projects[Company Name], an esteemed leader in the paint industry, is proud to introduce our latest innovative product: Gunmetal Spray Paint. This cutting-edge addition to our wide range of paints is designed to elevate the style and durability of any DIY project. Whether it's revamping furniture, sprucing up your car, or adding a touch of elegance to your home decor, Gunmetal Spray Paint is the ideal choice for achieving a sleek and metallic finish.With its unique formulation, Gunmetal Spray Paint delivers exceptional quality and performance, making it the go-to option for both professional painters and DIY enthusiasts. Our paint is formulated with the highest industry standards, ensuring a flawless, long-lasting finish that will withstand the test of time. Whether you're working with wood, metal, plastic, or any other surface, our Gunmetal Spray Paint adheres perfectly, providing a smooth and consistent coat that enhances the natural beauty of any object.Beyond its outstanding durability, Gunmetal Spray Paint sets itself apart with its remarkable versatility. Its sleek, metallic finish adds a touch of elegance to any project, making it a popular choice for those looking to add a contemporary and sophisticated look to their creations. Whether you want to give an old piece of furniture a modern makeover or add a unique touch to your car's exterior, Gunmetal Spray Paint offers endless possibilities for unleashing your creativity.Our Gunmetal Spray Paint also boasts several features that make it user-friendly and convenient. The spray can's ergonomic design ensures a comfortable grip, allowing for easy and precise application. Its quick-drying formula means you can work efficiently, saving you time and effort. Additionally, the paint's low odor means you can comfortably use it indoors without worrying about unpleasant fumes. Gunmetal Spray Paint makes DIY projects more enjoyable, allowing you to focus on bringing your vision to life.Furthermore, our commitment to sustainability is reflected in the manufacturing process of our Gunmetal Spray Paint. We prioritize environmental responsibility by utilizing eco-friendly materials and following eco-conscious practices. By choosing our Gunmetal Spray Paint, you not only enhance the aesthetics of your projects but also contribute to a greener and more sustainable future.To ensure customer satisfaction, we have conducted extensive testing on our Gunmetal Spray Paint to meet the highest quality standards. Our paint undergoes rigorous assessments for color accuracy, durability, and performance. This meticulous approach guarantees that our customers receive a product they can trust to deliver consistent and exceptional results.As part of our dedication to customer service, we also provide detailed instructions on how to achieve the best outcomes with Gunmetal Spray Paint. We offer tips and techniques for proper preparation, application, and maintenance to help both amateurs and professionals achieve professional-looking finishes. Our aim is to empower our customers with the knowledge and tools they need to achieve their desired results.In conclusion, [Company Name]'s Gunmetal Spray Paint revolutionizes the industry by combining style with durability. It offers unmatched versatility, easy application, and eco-friendly features. Whether you're a homeowner looking to add elegance to your living space or a DIY enthusiast seeking to breathe new life into old furniture, Gunmetal Spray Paint is the perfect choice. With [Company Name]'s commitment to quality and customer satisfaction, you can trust that our Gunmetal Spray Paint will exceed your expectations and elevate your DIY projects to new heights of excellence.

Top-Quality Paint Booths for Your Auto Body Needs

: The Importance of Choosing the Right Automotive Painting BoothAs an auto body shop owner, you understand the importance of providing high-quality automotive painting services to your customers. However, achieving flawless paint finishes is not always easy, and it requires not only the skill of your technicians but also the right equipment. In particular, the automotive painting booth is a crucial piece of equipment that can significantly impact the quality of your painting results. In this blog post, we will discuss the importance of choosing the right automotive painting booth and how it can benefit your business.What is an Automotive Painting Booth?An automotive painting booth, also known as a spray booth, is a specialized enclosure designed to contain paint overspray and to provide a controlled environment for the painting process. The booth typically consists of a large structure made of metal or other materials that encloses the vehicle being painted, along with a system of fans, filters, and ventilation ducts. The booth creates a positive pressure, which keeps dust and contaminants out and prevents the escape of overspray. Additionally, it helps maintain an ideal temperature and humidity level for the paint to dry properly and achieve a smooth, even finish.Why the Right Automotive Painting Booth Matters?There are various types of automotive painting booths available on the market, each with its own set of features and specifications. However, not all booths are created equal, and choosing the wrong one can lead to several negative consequences. Here are some reasons why choosing the right automotive painting booth matters:1. Better Quality of Painting ResultsOne of the primary benefits of using a high-quality automotive painting booth is that it can significantly improve the quality of your painting results. A well-designed booth will provide a controlled environment that minimizes the impact of external factors such as dust, humidity, and temperature fluctuations. This, in turn, results in more consistent and uniform finishes that are free of blemishes, runs, or other imperfections.2. Increased Efficiency and ProductivityAnother key advantage of using the right automotive painting booth is that it can increase your efficiency and productivity. A booth that is equipped with advanced features such as a heated air make-up system, adjustable motors, and energy-efficient lighting can help you paint more cars in less time. Moreover, a high-quality booth can reduce the need for costly and time-consuming touch-ups, which can improve your bottom line.3. Compliance with Safety StandardsOperating an auto body shop carries inherent risks, and ensuring the safety of your workers and customers is of paramount importance. Using an automotive painting booth that complies with safety standards such as NFPA 33 or OSHA regulations can help you reduce the risk of fire, explosion, or other hazards. Additionally, a booth that is properly ventilated and equipped with high-quality filters can protect your workers from inhaling dangerous fumes or particulates.4. Enhanced Environmental ResponsibilityAs an automotive painting professional, you have a responsibility to reduce your environmental impact and comply with relevant regulations. Choosing an automotive painting booth that is designed with environmental responsibility in mind can help you achieve these goals. For example, using a booth that is equipped with energy-efficient lighting, low-VOC filters, or a recirculation mode can reduce your energy consumption and waste generation, while also improving your compliance with EPA or other regulations.In conclusion, choosing the right automotive painting booth is crucial for achieving high-quality painting results, improving efficiency and productivity, complying with safety standards, and enhancing environmental responsibility. At Tools USA, we offer a wide range of high-quality, durable, and cost-effective automotive painting booths for every budget and requirement. Contact us today to learn more about our products and services.

Efficient Infrared Paint Curing Lamp for Quick Drying and Professional Finish

Infrared Paint Curing Lamp Revolutionizes Automotive IndustryIn a world where innovation and technology continue to advance at a rapid pace, one company stands out as a leader in the automotive industry. With a commitment to providing cutting-edge solutions for their clients, {company name} has once again set a new standard with their latest product: the Infrared Paint Curing Lamp.This revolutionary tool has the power to completely transform the way automotive paint is cured, offering a more efficient and effective solution for body shops and car manufacturers alike. By harnessing the power of infrared technology, {company name} has created a product that is not only environmentally friendly, but also highly efficient and cost-effective.So, what exactly sets the Infrared Paint Curing Lamp apart from other curing methods? First and foremost, this innovative tool significantly reduces the curing time for automotive paint. Traditional curing methods often require hours of drying time, which can result in significant downtime for body shops and manufacturers. In contrast, the Infrared Paint Curing Lamp is able to cure paint in a fraction of the time, allowing for faster turnaround and increased productivity.In addition to its speed, this cutting-edge lamp also offers a superior level of precision when it comes to curing paint. The use of infrared technology allows for more uniform and consistent drying, resulting in a flawless finish every time. This level of accuracy is crucial in the automotive industry, where quality and attention to detail are of the utmost importance.Furthermore, the Infrared Paint Curing Lamp is exceptionally energy-efficient, consuming significantly less power than traditional curing methods. This not only reduces operating costs for body shops and manufacturers, but also minimizes the environmental impact of the curing process.{Company name} has a long history of providing top-of-the-line solutions for the automotive industry, and their Infrared Paint Curing Lamp is no exception. With a commitment to innovation and customer satisfaction, this forward-thinking company is at the forefront of modernizing the way automotive paint is cured.As the demand for more efficient and environmentally friendly solutions continues to grow, the Infrared Paint Curing Lamp is poised to revolutionize the way paint is cured in the automotive industry. Its unparalleled speed, precision, and energy efficiency make it a game-changer for body shops and manufacturers around the world.In conclusion, the Infrared Paint Curing Lamp from {company name} is a shining example of the company's dedication to providing cutting-edge solutions for the automotive industry. With its revolutionary technology and unparalleled performance, this innovative tool is poised to transform the way automotive paint is cured, setting a new standard for efficiency and quality in the industry.

Best Spray Nozzle for Effective Weed Spraying

The {Company Name}, a leading manufacturer of agricultural and gardening equipment, recently unveiled their latest innovation in the field of weed control – the new {Product Name} Spray Nozzle for Weed Sprayers. This new and improved spray nozzle is designed to provide more precise and efficient coverage, making it easier than ever for farmers and gardeners to combat invasive weeds.The {Company Name} has been a trusted name in the agricultural industry for over 30 years, and they are known for their commitment to quality and innovation. With a focus on providing practical solutions for farmers and gardeners, the company has constantly strived to develop products that make life easier for those working in the field.The {Product Name} Spray Nozzle is the latest example of their dedication to meeting the needs of their customers. This new nozzle is designed to fit most standard weed sprayers, making it a versatile and convenient option for anyone in need of a reliable weed control solution. The nozzle is constructed from high-quality, durable materials, ensuring that it will withstand the rigors of regular use, and provide reliable performance over the long term.One of the key features of the {Product Name} Spray Nozzle is its adjustable spray pattern. This feature allows users to customize the nozzle to suit their specific needs, whether they are targeting a small, localized area or covering a larger expanse of land. This level of flexibility ensures that the nozzle can be used for a wide range of applications, making it a valuable addition to any farmer or gardener’s toolkit.In addition to its adjustable spray pattern, the {Product Name} Spray Nozzle also offers improved precision and efficiency. The nozzle is designed to deliver a consistent and controlled spray, ensuring that herbicides and other weed control products are applied only where they are needed, minimizing waste and maximizing the effectiveness of the treatment. This level of precision is crucial for ensuring that invasive weeds are effectively managed, without harming surrounding vegetation.Furthermore, the {Product Name} Spray Nozzle is also designed to minimize the potential for drift, which is a common concern when applying herbicides and other chemical treatments. By delivering a targeted and controlled spray, the nozzle helps to reduce the risk of unintended damage to nearby crops or ornamental plants, providing peace of mind for users.The {Company Name} understands that weed control is a constant challenge for farmers and gardeners, and they are committed to providing practical and effective solutions. With the introduction of the {Product Name} Spray Nozzle, they have once again demonstrated their dedication to meeting the evolving needs of their customers.To find out more about the {Product Name} Spray Nozzle for Weed Sprayers and other innovative products from the {Company Name}, visit their website or contact a local distributor. With their reputation for quality and reliability, the {Company Name} is a name you can trust for all your agricultural and gardening needs.

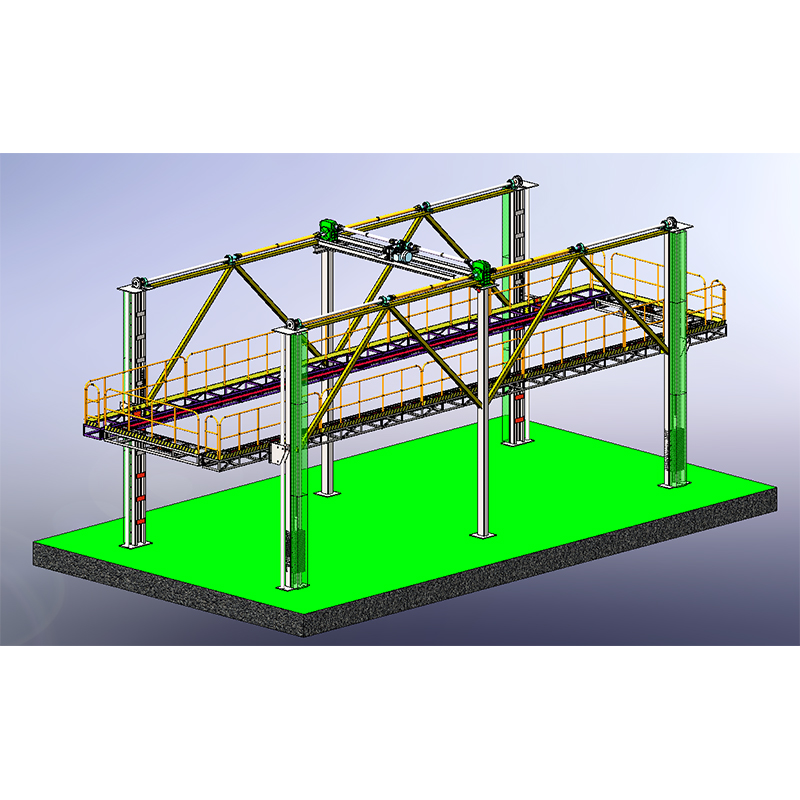

Benefits of a On-Floor Towline Conveyor System

On-Floor Towline Conveyor Revolutionizes Material Handling in Manufacturing IndustryIn today’s fast-paced manufacturing industry, companies are constantly looking for innovative solutions to improve their material handling processes. Efficiency, safety, and cost-effectiveness are paramount, and choosing the right equipment can make all the difference. That’s where the On-Floor Towline Conveyor, offered by {}, comes into play.{} is a leading provider of material handling solutions, with a strong focus on customer satisfaction and high-quality products. With a reputation for innovation and reliability, the company has been at the forefront of the industry for over 30 years. Their commitment to excellence has made them a trusted partner for manufacturers seeking to streamline their operations.The On-Floor Towline Conveyor is one of {}’s flagship products, and for good reason. This state-of-the-art system is designed to transport materials and products throughout the manufacturing facility, providing a seamless and efficient flow of goods. Unlike traditional conveyors, the On-Floor Towline Conveyor offers greater flexibility and adaptability, making it a perfect fit for a wide range of industries and applications.One of the key features of {}’s On-Floor Towline Conveyor is its modular design, which allows for easy customization and expansion. This means that as a company grows and its needs change, the conveyor system can be easily adapted to accommodate new requirements. This level of flexibility is essential in today’s dynamic business environment, where the ability to scale and adapt quickly is a competitive advantage.In addition to its modular design, the On-Floor Towline Conveyor is also known for its reliability and low maintenance requirements. {} has integrated advanced technology and high-quality materials into the design of the system, ensuring that it can withstand the demands of a fast-paced manufacturing environment. This translates to minimal downtime and reduced operating costs for companies that choose {}’s solution.The On-Floor Towline Conveyor also prioritizes safety, with features such as collision avoidance systems and fail-safe mechanisms. In an industry where workplace safety is a top concern, this is a crucial aspect of the system’s design. By minimizing the risk of accidents and ensuring the well-being of workers, {}’s solution provides peace of mind for both companies and their employees.Furthermore, the On-Floor Towline Conveyor offers enhanced efficiency, allowing for the seamless movement of materials and products with minimal effort. This not only improves overall productivity but also maximizes floor space utilization, a valuable asset in crowded manufacturing facilities. By optimizing the use of space and resources, companies can achieve greater output and profitability.The impact of {}’s On-Floor Towline Conveyor has been felt across various industries, from automotive manufacturing to pharmaceutical production. Its versatility and effectiveness have made it a popular choice for companies looking to modernize their material handling processes and gain a competitive edge in the market. As the manufacturing landscape continues to evolve, {} remains at the forefront of innovation, developing cutting-edge solutions to meet the changing needs of its customers.In conclusion, the On-Floor Towline Conveyor offered by {} is a game-changer in the manufacturing industry, revolutionizing material handling with its flexibility, reliability, and efficiency. As companies strive to stay ahead of the curve and meet the demands of a rapidly evolving market, {}’s solution is a valuable asset that can drive growth and success. With a track record of excellence and a commitment to continuous improvement, {} is poised to remain a leader in the material handling space for years to come.

Highly Efficient and Versatile Steam Spray Nozzle for Various Applications

Steam Spray Nozzle Enhances Cleaning Efficiency for Industrial ApplicationsIndustrial cleaning processes are constantly evolving with advancements in technology and innovation. One of the latest breakthroughs in this field is the development of the Steam Spray Nozzle, a cutting-edge cleaning solution that is revolutionizing the way industrial equipment and machinery are maintained and sanitized.The Steam Spray Nozzle, produced by a leading company in the industrial cleaning equipment industry, is designed to deliver a powerful and efficient cleaning performance. Its unique design and advanced technology make it an ideal solution for a wide range of industrial cleaning applications, including the removal of grease, oil, dirt, and other contaminants from manufacturing equipment, processing machinery, and various industrial surfaces.The company behind the Steam Spray Nozzle is recognized for its commitment to delivering high-quality, reliable, and innovative cleaning solutions to its customers. With a strong focus on research and development, the company has been able to stay at the forefront of the industry, constantly introducing new and improved products that meet the evolving needs of its clients.The Steam Spray Nozzle is a testament to the company's dedication to innovation and excellence. It is equipped with state-of-the-art technology that allows it to generate a powerful and consistent steam spray, ensuring thorough and effective cleaning. The high-temperature steam effectively breaks down tough residues and eliminates bacteria and germs, making it an essential tool for maintaining a clean and hygienic industrial environment.In addition to its superior cleaning performance, the Steam Spray Nozzle is designed for ease of use and versatility. It can be easily integrated into existing cleaning systems and equipment, making it a cost-effective solution for businesses looking to enhance their cleaning processes. Its compact and durable design ensures long-term reliability and performance, even in the most demanding industrial settings.Furthermore, the company provides comprehensive support and maintenance services for the Steam Spray Nozzle, ensuring that its customers can maximize the benefits of this innovative cleaning solution. With a team of highly trained and experienced technicians, the company is committed to offering exceptional assistance to its clients, assisting them with installation, troubleshooting, and maintenance of the Steam Spray Nozzle and other cleaning equipment.The market response to the Steam Spray Nozzle has been overwhelmingly positive, with various industries recognizing its potential to deliver significant improvements in cleaning efficiency and productivity. From food processing plants to automotive manufacturing facilities, businesses are realizing the value of investing in this advanced cleaning technology to streamline their operations and maintain high cleanliness standards.As the demand for effective and environmentally friendly cleaning solutions continues to grow, the Steam Spray Nozzle is poised to play a key role in shaping the future of industrial cleaning practices. With its exceptional performance, durability, and versatility, it is set to become a staple tool for businesses looking to elevate their cleaning processes and achieve superior results.In conclusion, the Steam Spray Nozzle represents a significant advancement in industrial cleaning technology, offering a powerful, efficient, and versatile solution for a wide range of cleaning applications. With the backing of a reputable and innovative company, this cutting-edge cleaning solution is set to make a lasting impact on the industrial cleaning industry, ushering in a new era of enhanced cleaning efficiency and productivity.

Ultimate Guide to Drag Chain Conveyors: Features, Benefits, and Applications

**Innovative Drag Chain Conveyor Revolutionizes Material Handling in Manufacturing Industry**The manufacturing industry is constantly seeking innovative solutions to improve efficiency and productivity. One of the key challenges in this industry is effective material handling, which can significantly impact the overall production process. To address this challenge, [Company Name] has introduced a cutting-edge Drag Chain Conveyor that is set to revolutionize the way materials are transported within manufacturing facilities.The Drag Chain Conveyor, developed by [Company Name], is a highly versatile and efficient system designed to handle a wide range of materials, including powders, grains, and abrasive materials. Unlike traditional conveyor systems, this innovative solution features a robust chain that carries the material along the conveyor path, providing a reliable and smooth transport mechanism. The conveyor is also equipped with advanced controls and automation features, allowing for precise speed and direction adjustments, as well as seamless integration with other material handling equipment.One of the key advantages of the Drag Chain Conveyor is its ability to handle materials with varying sizes and shapes, making it suitable for diverse manufacturing processes. The conveyor's flexible design allows for easy customization to meet specific material handling requirements, providing a seamless and efficient solution for a wide range of industries, including food processing, pharmaceuticals, chemicals, and more.In addition to its versatility, the Drag Chain Conveyor is also designed with durability and reliability in mind. The robust construction and high-quality materials ensure that the conveyor can withstand the rigors of industrial environments, minimizing downtime and maintenance costs. This focus on reliability and longevity makes the conveyor an ideal investment for manufacturing facilities looking to improve their material handling operations.Furthermore, the Drag Chain Conveyor is also designed with the principles of sustainability in mind. It is equipped with energy-efficient motors and drives, resulting in lower power consumption and reduced environmental impact. By integrating this innovative conveyor system into their operations, manufacturing facilities can contribute to their sustainability goals while optimizing their material handling processes.[Company Name] has a long-standing reputation for delivering high-quality material handling solutions to the manufacturing industry. With a strong focus on innovation and customer satisfaction, the company has garnered a loyal customer base and established itself as a leader in the field. The introduction of the Drag Chain Conveyor further solidifies [Company Name]'s commitment to providing cutting-edge solutions that meet the evolving needs of the manufacturing industry.The company's dedicated team of engineers and experts have worked tirelessly to develop and refine the Drag Chain Conveyor, ensuring that it meets the highest standards of performance, reliability, and efficiency. With a customer-centric approach, [Company Name] also provides comprehensive support and service to ensure that the conveyor seamlessly integrates into each client's specific manufacturing environment.The Drag Chain Conveyor has already been met with widespread anticipation and positive feedback from industry professionals. Manufacturing facilities are eagerly adopting this innovative solution to streamline their material handling processes, improve operational efficiency, and ultimately enhance their bottom line.As the manufacturing industry continues to evolve, the demand for advanced material handling solutions will only grow. The Drag Chain Conveyor from [Company Name] represents a significant leap forward in this domain, offering a game-changing solution that is poised to set new standards for material handling in manufacturing facilities. With its versatility, reliability, and sustainability benefits, this innovative conveyor system is set to make a profound impact on the industry and revolutionize the way materials are transported within manufacturing facilities.

Powder Coating System for Ovens: Enhancing Efficiency and Aesthetics

Title: Innovations in Oven Powder Coating System Bring Advanced Efficiency and PerformanceIntroduction:In the ever-evolving world of industrial manufacturing, the need for highly efficient and effective coating systems continues to grow. In response to this demand, a renowned company has unveiled a groundbreaking innovation - the Oven Powder Coating System. Built on cutting-edge technology and quality performance, this system aims to revolutionize the coating process, offering unparalleled efficiency and enhanced results for manufacturing industries worldwide.Providing a comprehensive solution to the challenges faced by traditional coating systems, the Oven Powder Coating System offers a range of benefits, including:1. Increased Efficiency: With advanced automation features and streamlined design, the system significantly reduces processing time and optimizes productivity. This enables manufacturers to meet demanding production targets while maintaining high-quality standards.2. Enhanced Performance: The system's advanced controls and precise application process ensure uniform coating thickness, resulting in consistent and flawless finishes. The superior adhesion properties of the powder make it highly resistant to chipping, cracking, and corrosion, thus extending the lifespan of coated products.3. Eco-Friendly Solution: In line with global sustainability efforts, this innovative system employs environmentally friendly, solvent-free powder coatings. These coatings not only eliminate hazardous emissions associated with traditional liquid coatings but also reduce energy consumption through an efficient curing process.4. Versatility: The Oven Powder Coating System caters to diverse industrial applications, including automotive, furniture, appliances, and architectural materials. It is compatible with various materials such as metal, wood, plastic, and glass, delivering seamless results on different surfaces.5. Quality Assurance: The system is equipped with advanced monitoring and inspection tools that ensure process consistency and product quality. Real-time data collection and analysis enable manufacturers to make informed decisions, optimize operations, and respond promptly to any issues that may arise.Company Overview:Founded in [year], [Company Name] has been at the forefront of pioneering innovations in the industrial coating industry. The company has gained a reputation for delivering high-quality, cutting-edge solutions that address the needs of diverse manufacturing sectors.With a focus on research and development, [Company Name] has built a team of experienced engineers and technicians who continuously work towards developing advanced coating systems. Their commitment to innovation, combined with a customer-centric approach, has allowed the company to cater to the evolving demands of its global clientele.The Oven Powder Coating System is the latest addition to [Company Name]'s portfolio. Leveraging years of industry experience and expertise, the company has successfully integrated the most efficient and reliable features into this system. They have also ensured compatibility with existing manufacturing processes, making it easy for businesses to integrate this breakthrough technology seamlessly.Conclusion:The introduction of the Oven Powder Coating System delivers a game-changing solution for the manufacturing industry. Combining increased efficiency, enhanced performance, and an eco-friendly approach, this system enables manufacturers to achieve higher production targets without compromising on quality. With the backing of [Company Name]'s profound expertise and commitment to innovation, the future of industrial coating looks promising, and manufacturers can anticipate improved productivity, lower costs, and superior finishes in their operations.

Top Truck Spray Booths for Your Business

Truck Spray Booth: Revolutionizing the Automotive IndustryIn recent years, the automotive industry has undergone significant developments in technology and innovation. One of the key areas where this revolution can be seen is in the field of painting and coating of vehicles. With the demand for high-quality finishes and efficient painting processes growing, the need for advanced equipment has become more crucial than ever before. This is where the Truck Spray Booth, a cutting-edge innovation developed by (company name), comes into play.The Truck Spray Booth is a revolutionary piece of equipment that has been designed to meet the specific needs of commercial vehicle painting. It is a state-of-the-art, fully enclosed system that provides a controlled environment for painting large vehicles such as trucks, buses, and trailers. This innovative booth is equipped with advanced ventilation and filtration systems to ensure a clean and safe working environment, as well as efficient drying and curing capabilities for a flawless finish.One of the standout features of the Truck Spray Booth is its versatility. Unlike traditional paint booths, which are tailored for smaller vehicles, the Truck Spray Booth is designed to accommodate the size and shape of large commercial vehicles without compromising on quality. This flexibility allows automotive manufacturers and painting shops to streamline their processes and increase productivity without sacrificing the quality of the final product.The (company name) has a rich history of innovation and excellence in the automotive industry. With over 20 years of experience, the company has established itself as a leading provider of advanced equipment and solutions for vehicle painting and refinishing. Their commitment to continuous improvement and customer satisfaction has earned them a reputation for reliability and high-quality products.The Truck Spray Booth is the latest addition to (company name)'s portfolio of innovative solutions for the automotive industry. It is the result of extensive research and development, as well as collaboration with industry experts to address the specific challenges of painting large commercial vehicles. The company's dedication to pushing the boundaries of technology and design is evident in every aspect of the Truck Spray Booth, from its robust construction to its intuitive and user-friendly controls.As the automotive industry continues to evolve, the demand for efficient and sustainable painting solutions is expected to grow. The Truck Spray Booth is well-positioned to meet this demand, thanks to its advanced features and proven performance. With its ability to reduce paint wastage, improve energy efficiency, and enhance the overall painting process, the Truck Spray Booth is set to revolutionize the way commercial vehicles are painted and refinished.In addition to its technical capabilities, the Truck Spray Booth is also designed with the environment in mind. It incorporates advanced technologies for capturing and treating paint overspray, reducing emissions, and minimizing environmental impact. This commitment to sustainability aligns with the growing focus on eco-friendly practices within the automotive industry, making the Truck Spray Booth a responsible choice for businesses looking to reduce their carbon footprint.The launch of the Truck Spray Booth is a significant milestone for (company name) and a testament to their ongoing dedication to innovation and customer satisfaction. With its potential to transform the commercial vehicle painting process, the Truck Spray Booth represents a new era in automotive painting technology. As the industry continues to evolve, the company remains committed to setting new standards and delivering cutting-edge solutions that drive progress and success for their customers.In conclusion, the Truck Spray Booth is a game-changer for the automotive industry, offering a powerful combination of advanced technology, versatility, and sustainability. With its ability to meet the specific needs of commercial vehicle painting and refinishing, it is set to become an indispensable asset for automotive manufacturers and painting shops around the world. As the industry embraces the future of vehicle painting, the Truck Spray Booth stands out as a prime example of innovation and excellence, setting a new standard for quality and efficiency.

Efficient and Durable Powder Coating Line for Vertical Applications

[Company Name], a leading manufacturer of industrial coating equipment, has recently introduced a state-of-the-art Vertical Powder Coating Line to enhance its offerings in the field of surface finishing solutions. The new powder coating line is designed to meet the growing demand for high-quality, efficient, and environmentally friendly coating solutions for various industries.The Vertical Powder Coating Line features advanced technology and innovative design to provide superior performance and precision in the application of powder coatings. This new addition to the company's product lineup is a testament to [Company Name]'s commitment to continuous improvement and innovation in the field of industrial coating equipment.With a focus on versatility and efficiency, the Vertical Powder Coating Line is capable of handling a wide range of parts and components, making it an ideal solution for manufacturers across different industries. Whether dealing with small, intricate parts or large, complex assemblies, this powder coating line is equipped to deliver consistent and uniform coating results, ensuring a high-quality finish on every product.One of the key highlights of the Vertical Powder Coating Line is its fully automated operation, which reduces the need for manual labor and minimizes the risk of errors in the coating process. This not only improves efficiency but also enhances the overall quality and reliability of the coating application. Additionally, the automated system allows for quick changeovers between different colors and materials, enabling manufacturers to easily adapt to varying production requirements.In line with [Company Name]'s commitment to sustainability, the Vertical Powder Coating Line is designed to minimize waste and optimize the use of resources. The system is equipped with advanced recovery and recycling features that help to reduce material wastage and lower the overall environmental impact of the coating process. By promoting efficient use of resources, this powder coating line supports the adoption of eco-friendly practices in manufacturing operations.Furthermore, the Vertical Powder Coating Line incorporates advanced control and monitoring systems to ensure consistent and precise application of powder coatings. With real-time data tracking and adjustment capabilities, manufacturers can fine-tune the coating process to achieve the desired thickness, texture, and appearance of the finish. This level of control not only enhances the quality of the products but also allows for greater flexibility in meeting custom requirements.As part of [Company Name]'s dedication to customer satisfaction, the Vertical Powder Coating Line is backed by comprehensive support services, including installation, training, and maintenance. The company's team of technical experts is available to provide guidance and assistance to ensure seamless integration of the powder coating line into the customer's production facility. This commitment to customer support underscores [Company Name]'s focus on delivering value beyond just the equipment itself.In addition to its technical capabilities, the Vertical Powder Coating Line reflects [Company Name]'s commitment to continuous improvement and customer-centric innovation. By leveraging feedback from customers and industry trends, the company has developed a solution that addresses the evolving needs of manufacturers seeking efficient and reliable coating equipment.With the introduction of the Vertical Powder Coating Line, [Company Name] reaffirms its position as a trusted partner for manufacturers seeking cutting-edge solutions for surface finishing and industrial coating. The company's dedication to quality, innovation, and sustainability is evident in this latest addition to its product portfolio, which is poised to set new benchmarks in the field of powder coating technology. As industries continue to prioritize efficiency and quality in their manufacturing processes, [Company Name] remains at the forefront of providing advanced solutions to meet these demands.