Advanced Robotic Powder Coating Solutions for Optimal Results

By:Admin

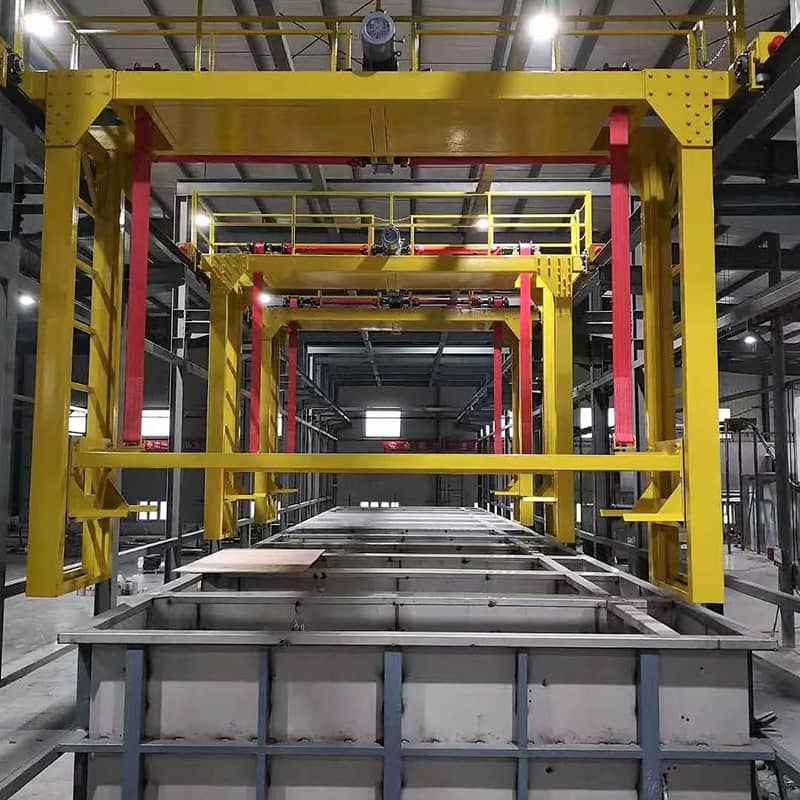

Innovative technology has always played a vital role in shaping the manufacturing industry. From automation to artificial intelligence, advancements in technology have enabled companies to streamline their operations and improve efficiency. One such advancement that is making waves in the industry is Robotic Powder Coating.

Robotic Powder Coating, also known as automated powder coating, is a cutting-edge technology that has revolutionized the way manufacturers apply coatings to their products. This technology utilizes robotic arms to apply a powdered coating to the surface of a material, which is then cured to produce a durable and high-quality finish.

One company that has been at the forefront of this technological innovation is {}. Founded in 1990, {} has been a pioneer in the development and implementation of robotic powder coating systems. With a strong focus on research and development, the company has continually pushed the boundaries of what is possible with this technology, leading to significant advancements in the industry.

The use of robotic powder coating has numerous advantages over traditional coating methods. One of the most significant benefits is the precision and consistency that robotic arms can achieve. This technology allows for uniform and even application of the powder coating, eliminating the inconsistencies and imperfections that can occur with manual application. This results in a superior finish and a higher-quality product.

In addition to precision, robotic powder coating also offers increased efficiency and productivity. By automating the coating process, manufacturers can significantly reduce their production time and costs. The speed and accuracy of robotic arms allow for quicker turnaround times, leading to higher output and increased profitability for companies.

Furthermore, robotic powder coating is also environmentally friendly. Compared to traditional liquid coatings, powder coatings produce minimal waste and have lower levels of volatile organic compounds (VOCs), making them a more sustainable and eco-friendly option. This aligns with the growing emphasis on sustainability in the manufacturing industry and has positioned robotic powder coating as a preferred choice for many companies.

The applications of robotic powder coating are vast and diverse, spanning across various industries such as automotive, aerospace, furniture, and appliances. With its ability to coat a wide range of materials, including metal, plastic, and composites, this technology has become an integral part of the manufacturing process for many companies.

One of the key reasons behind the success of {} in the robotic powder coating industry is their commitment to continuous improvement and innovation. The company has invested heavily in research and development to create cutting-edge technology that meets the evolving needs of manufacturers. By staying at the forefront of technological advancements, {} has been able to provide their customers with state-of-the-art robotic powder coating systems that deliver exceptional results.

In addition to their technological advancements, {} also offers comprehensive support and services to their clients. From installation and training to maintenance and troubleshooting, the company provides end-to-end solutions to ensure that their customers can maximize the benefits of robotic powder coating in their operations.

Looking ahead, the future of robotic powder coating appears promising. As technology continues to advance, we can expect to see further improvements in efficiency, precision, and sustainability, making this technology even more appealing to manufacturers worldwide. With {} leading the charge in innovation, the industry is poised for continued growth and success.

In conclusion, robotic powder coating has become a game-changer in the manufacturing industry, offering numerous benefits such as precision, efficiency, and sustainability. With companies like {} at the forefront of this technological revolution, we can expect to see widespread adoption of robotic powder coating systems, further shaping the future of manufacturing.

Company News & Blog

High-quality Adjustable Spray Nozzle for Versatile Watering Needs

Introducing a Revolutionary Adjustable Spray NozzleIn today's fast-paced world, efficiency and convenience are key factors when it comes to everyday tasks. Whether it is watering the garden, washing the car, or cleaning outdoor surfaces, having the right tools can make a world of difference. This is why we are excited to introduce our latest product, the Adjustable Spray Nozzle.This innovative and versatile spray nozzle is designed to provide users with a range of spray options, making it the perfect tool for a wide variety of outdoor tasks. With its adjustable nozzle, users can easily switch between a gentle mist for delicate plants, a powerful jet for cleaning tough stains, and everything in between. This flexibility not only makes the Adjustable Spray Nozzle incredibly convenient to use, but also ensures that it is suitable for any outdoor job.One of the key features of the Adjustable Spray Nozzle is its durability. Made from high-quality materials, this spray nozzle is built to withstand the rigors of outdoor use. Whether it is exposed to harsh weather conditions or rough handling, users can rely on the Adjustable Spray Nozzle to continue performing at its best.Moreover, the ergonomically designed handle ensures that users can comfortably hold and operate the nozzle for extended periods of time, reducing fatigue and making outdoor tasks more enjoyable. Additionally, the nozzle is designed to be compatible with standard garden hoses, making it easy to incorporate into any existing outdoor watering or cleaning setup.In addition to its performance and durability, the Adjustable Spray Nozzle is also designed with sustainability in mind. With its efficient water usage and versatile spray settings, users can minimize water wastage while still achieving their desired results. This not only benefits the environment but also helps users save on their water bills.At {}, we are committed to providing our customers with high-quality, innovative products that make their lives easier. With the Adjustable Spray Nozzle, we have once again delivered on this promise, offering a solution that is not only functional and practical but also environmentally friendly. This product is a testament to our dedication to continuous improvement and our commitment to meeting the evolving needs of our customers.The Adjustable Spray Nozzle is a game-changer for anyone who takes pride in maintaining their outdoor spaces. From garden enthusiasts to car enthusiasts, this versatile tool is sure to become a staple in their outdoor toolkit. With its ease of use, durability, and efficiency, the Adjustable Spray Nozzle is set to redefine the way outdoor tasks are performed.In conclusion, the Adjustable Spray Nozzle is a game-changer in outdoor watering and cleaning. Its innovative design, durability, and sustainability make it a must-have for anyone who takes pride in their outdoor spaces. With this latest addition to our product range, we are proud to continue our tradition of providing our customers with the tools they need to make their lives easier. The Adjustable Spray Nozzle is a testament to our commitment to innovation and our dedication to customer satisfaction.

Buy Paint Spray Booths and Powder Spray Booths Online and Save up to 17%!

Paint Spray Booths | Powder Spray Booths: Offering High-Quality Solutions to the Automotive Industry[City], [Date] - In today's competitive market, the automotive industry faces various challenges, one of which is ensuring the highest quality finishes on vehicles. To meet this demand, [Company Name] introduces its extensive range of paint and powder spray booths, providing top-of-the-line solutions to automotive manufacturers and repair shops. The company's commitment to delivering high-quality products has made it a leader in the industry.[Company Name] takes pride in its state-of-the-art paint and powder spray booths, designed to meet the specific needs of customers. These booths offer a controlled environment for optimal painting and finishing results, ensuring a flawless end product. With their advanced ventilation systems and safety features, [Company Name]'s spray booths provide a safe and efficient working environment, prioritizing the well-being of workers.One of the main advantages of [Company Name]'s spray booths is their versatility. The company offers a wide range of booth sizes and configurations, allowing customers to choose the option that best suits their requirements. Whether it's a small repair shop or a large-scale manufacturing facility, [Company Name] has the perfect solution to accommodate any project size.Moreover, [Company Name]'s spray booths are equipped with cutting-edge technology, enabling precise control over temperature, humidity, and airflow. This level of control ensures consistent and high-quality finishes, meeting the demanding standards of the automotive industry. Additionally, their booths are designed to minimize overspray and eliminate dust particles, further enhancing the quality of the final product.Ensuring customer satisfaction is a top priority for [Company Name]. The company's team of experts works closely with each client to understand their specific needs and provide tailored solutions to meet them. By maintaining open lines of communication and accommodating unique requirements, [Company Name] has built a strong reputation for exceptional customer service.Furthermore, [Company Name] strives to exceed industry standards by continuously investing in research and development. The company keeps up with the latest advancements in spray booth technology, enabling them to offer cutting-edge products that optimize productivity, efficiency, and environmental sustainability. By providing environmentally friendly options, [Company Name] supports its clients in their efforts to reduce their carbon footprint and contribute to a greener future.As the automotive industry evolves, [Company Name] remains committed to innovation and improvement. With a focus on customer satisfaction and a dedication to delivering the highest quality solutions, the company continues to set new industry standards. By harnessing the power of advanced technology and expertise, [Company Name] empowers its customers to achieve outstanding results, solidifying its position as an industry leader.In conclusion, [Company Name] offers a comprehensive range of paint and powder spray booths that cater to the needs of the automotive industry. With their commitment to quality, exceptional customer service, and dedication to innovation, [Company Name] has firmly established itself as a trusted provider in the industry. By investing in their state-of-the-art spray booths, automotive manufacturers and repair shops can achieve superior finishes, streamline their operations, and stay ahead of the competition.For more information about [Company Name] and their paint and powder spray booths, please visit their website at: [Website URL].

Best Convection Ovens: Top-rated models for perfect home baking

Ovens are an essential tool in any kitchen, providing a means for cooking and baking a wide variety of dishes. The versatile nature of ovens has led to their widespread use in both residential and commercial settings. The {Company Name} prides itself on producing high-quality ovens that are both reliable and efficient.{Company Name} was founded in 1986 and has since become a leading manufacturer of kitchen appliances, including ovens, in the industry. The company's commitment to innovation and customer satisfaction has set it apart from its competitors, allowing it to establish a strong reputation for quality and reliability.The company's ovens are designed with the latest technology to provide users with a seamless cooking experience. From precise temperature control to efficient heat distribution, {Company Name}'s ovens are equipped with features that make cooking and baking easier and more enjoyable. In addition, the ovens are built to last, with durable materials and craftsmanship ensuring their longevity.One of the key features of {Company Name}'s ovens is their energy efficiency. With a focus on sustainability, the company has developed ovens that consume less energy while still delivering superior cooking performance. This not only benefits the environment but also helps users save on their energy bills.In terms of design, {Company Name} offers a range of ovens to suit different kitchen styles and cooking needs. Whether it's a built-in oven for a sleek, modern kitchen or a freestanding oven for a more traditional look, the company's product line caters to a diverse range of preferences. Additionally, the ovens come in various sizes to accommodate different cooking capacities, making them suitable for both small and large households.Beyond the product itself, {Company Name} also prioritizes customer service and support. The company's team of professionals is dedicated to assisting customers with any inquiries or issues they may have regarding their ovens. This commitment to customer care has earned {Company Name} a loyal customer base that continues to grow.In recent news, {Company Name} has announced the release of its latest line of ovens, featuring even more advanced technology and enhanced cooking capabilities. These new ovens are the result of extensive research and development, incorporating feedback from customers to ensure they meet the highest standards of performance and user satisfaction.One of the standout features of the new ovens is their smart functionality, which allows users to control and monitor the cooking process remotely. Through the use of a mobile app, users can preheat the oven, adjust the temperature, and receive notifications when their food is ready. This level of convenience is a testament to {Company Name}'s dedication to incorporating the latest innovations into its products.Furthermore, the new ovens boast improved cooking modes and settings, catering to a wider range of culinary preferences. Whether it's convection baking, broiling, or roasting, these ovens are designed to deliver consistent and delicious results. The addition of preset cooking programs also makes it easier for users to prepare their favorite dishes with just the touch of a button.In terms of design, the new ovens feature a sleek and modern aesthetic that complements a variety of kitchen styles. The user interface has been revamped for improved usability, featuring intuitive controls and a clear display for effortless operation.{Company Name}'s commitment to sustainability is also evident in the new ovens, as they are designed to be even more energy-efficient than previous models. This aligns with the company's dedication to reducing its environmental footprint and promoting eco-friendly practices.The release of the new line of ovens represents {Company Name}'s ongoing mission to provide customers with exceptional cooking solutions that enhance their culinary experiences. With a focus on quality, innovation, and customer satisfaction, {Company Name} continues to set the standard for excellence in the kitchen appliance industry.In conclusion, {Company Name} has established itself as a leading manufacturer of ovens, known for their quality, reliability, and commitment to customer satisfaction. The release of their latest line of ovens showcases the company's dedication to innovation and continuous improvement. With advanced technology, enhanced features, and a focus on sustainability, {Company Name} remains at the forefront of the kitchen appliance industry, offering customers a range of versatile and efficient ovens for their culinary needs.

Custom 14,000 GVW Race Trailer with Removable Bolt-On Toolboxes and Under-Deck Water Storage

In the world of racing, the need to transport equipment and vehicles from one location to another is of utmost importance. That's where the custom-built 2021 20ft x102 14,000GVW race trailer comes in.This trailer is designed to provide the necessary support, space, and safety to transport two racing rigs and essential equipment. It features a rectangular tubing frame, bolt-on toolboxes that can be removed for ramps, and 80 gallons of fresh water mounted under the deck. The locking gal gas can ensures that the fuel is always secure during transportation.What's more, this trailer is not just functional, but it's also aesthetically appealing. It boasts a powder coating finish that gives it a sleek look while also protecting it from rusting and corrosion. The powder coating process creates a hard, durable, and resistant finish that will last for a long time, saving you money on maintenance and repairs.If you are looking for a trailer that is durable, functional, and looks great, this custom-built 20ft x102 race trailer is an excellent choice. The powder coating finish ensures that it can withstand tough conditions, including harsh weather and long hours on the road.Finally, if you're interested in powder coating, you may also want to consider a 20ft powder coating oven, which is a device used to apply a coat of powder to a material or item. It's a great investment for businesses that require custom powder coating for their products. By owning this oven, you can save money in the long run and increase your business's productivity.In conclusion, the custom-built 2021 20ft x102 race trailer is a great investment for race teams and businesses that require reliable and safe transportation. The powder coating finish ensures that it looks great while also providing resistance against rust and other forms of damage. If you're interested in powder coating as well, consider investing in a 20ft powder coating oven for your business.

Revolutionary New Powder Coating Oven for Large-scale Projects

In a move to improve its production capacity and efficiency, a leading powder coating company has invested in a brand-new industrial oven that promises to revolutionize its coating processes. Manufactured by a reputable engineering firm, the large-scale oven is capable of producing high-quality coatings on large volumes of parts and products.The new oven features state-of-the-art technology that ensures precise temperature control and uniform heat distribution throughout the chamber. This is crucial in powder coating, as even the slightest temperature variations can have a significant impact on the final product's appearance and durability. With the carefully designed air-flow system and advanced heating elements, the oven provides consistent and reliable curing for a wide range of coating materials, including epoxies, polyesters, hybrids, and fluoropolymers.The oven's size is another impressive factor, as it can accommodate large parts and products up to 16 feet in length, 8 feet in height, and 8 feet in width. This translates to a massive increase in throughput for the company, as it can now handle bigger projects and batch sizes that were previously unfeasible. This feature is essential for companies that require quick turnaround times and high-volume production, such as manufacturers of automotive parts, industrial machinery, and consumer goods.The investment in the new oven is part of the company's strategic plan to stay ahead of the competition and meet the growing demands of its customers. With an expanding client base that demands high-quality finishes and fast turnaround, the company needed to upgrade its facilities to maintain its position as a leader in the powder coating industry.The company is committed to sustainable practices and reducing its carbon footprint, and the new oven contributes significantly to this goal. Its energy-efficient design and high-performance insulation allow it to use less fuel and reduce emissions, resulting in lower operating costs and environmental impact.David Smith, the company's CEO, expressed his excitement about the new addition to their production line. He said, "We're thrilled to have this new oven installed and fully operational. It's a game-changer for us, as it allows us to take on bigger projects, improve our quality control, and increase our throughput. We're committed to investing in the latest technology and providing the highest level of service to our customers."The company has been in operation for over a decade and has built a reputation for quality and reliability in the powder coating industry. Its clients include small businesses, multinational corporations, and government agencies, spanning diverse industries such as aerospace, construction, and medical equipment.In conclusion, the installation of the new industrial oven marks a significant milestone for the powder coating company, enabling it to provide better services to its clients, improve its production efficiency, and contribute to its sustainability goals. With its cutting-edge technology, large capacity, and energy-efficient design, the oven is set to become a vital tool in the company's operations and a valuable asset for its clients.

High-quality Powder Coating Oven for LPG Use

Lpg Powder Coating Oven Offers Cutting-Edge Technology for Superior Coating ResultsIn the world of industrial manufacturing, the process of powder coating has become an essential part of creating high-quality, durable products. Powder coating offers a cost-effective and environmentally-friendly alternative to traditional liquid paint, providing a durable and attractive finish to a wide range of products such as automotive parts, appliances, and metal furniture. As demand for powder coating continues to grow, companies are constantly seeking innovative and efficient solutions to improve their coating processes.It is in this highly competitive market that {Company Name}, a leading manufacturer of industrial ovens, has introduced their latest breakthrough in powder coating technology - the Lpg Powder Coating Oven. This cutting-edge oven is designed to provide superior coating results, precise temperature control, and increased operational efficiency, making it a game changer for businesses looking to optimize their powder coating process.With over 20 years of experience in the industry, {Company Name} has built a reputation for delivering high-quality, reliable industrial ovens that meet the diverse needs of their customers. Their commitment to innovation and excellence has led to the development of the Lpg Powder Coating Oven, which has quickly garnered attention for its advanced features and unmatched performance.One of the key features of the Lpg Powder Coating Oven is its state-of-the-art temperature control system. The oven is equipped with advanced sensors and digital controls that allow for precise monitoring and adjustment of the heating process, ensuring consistent and uniform heating throughout the coating cycle. This level of control is essential for achieving a high-quality finish and minimizing defects in the coating, ultimately leading to cost savings and improved product quality.Additionally, the Lpg Powder Coating Oven is designed for maximum energy efficiency, utilizing Lpg gas as a clean and efficient fuel source. This not only reduces the environmental impact of the coating process but also helps businesses reduce their operational costs. The oven is also equipped with insulation and airflow systems that minimize heat loss and improve heating efficiency, further enhancing its energy-saving capabilities.Another standout feature of the Lpg Powder Coating Oven is its versatile design, which allows for easy customization to meet the specific needs of different coating applications. Whether it's small parts or large assemblies, the oven can be tailored to accommodate a wide range of products, making it a flexible and adaptable solution for diverse manufacturing environments.To ensure the success of their customers, {Company Name} provides comprehensive support and training for the integration and operation of the Lpg Powder Coating Oven. Their team of experienced engineers and technicians work closely with clients to deliver personalized solutions and ongoing technical assistance, guaranteeing a seamless transition to the new technology and maximizing the benefits of the oven's advanced features.With its unmatched performance, energy efficiency, and versatility, the Lpg Powder Coating Oven by {Company Name} is poised to set a new standard for powder coating technology in the industrial manufacturing sector. By offering a solution that addresses the evolving needs of businesses and the environment, the company continues to demonstrate its commitment to driving innovation and providing value to its customers.As demand for powder coating continues to rise, the Lpg Powder Coating Oven is poised to become a sought-after solution for businesses seeking to elevate their coating processes and achieve superior results. With its advanced features and support services, {Company Name} is set to make a significant impact on the industry and solidify its position as a leading provider of industrial ovens and coating solutions.

Professional Spray Booth Kit for Paint, Craft, and Hobby enthusiasts

article about the benefits and uses of a spray booth kit.IntroductionSpray booths are essential for anyone who is serious about paint craft, airbrushing, and other related hobbies. They are specifically designed to help prevent the inhalation of harmful fumes and particulates that are often generated when working with paints and other chemicals. However, simply having a spray booth is not enough. It needs to function properly and have the necessary features that make it efficient and effective. This is where the New Airbrush Spray Booth Kit Paint Craft Odor Extractor Hobby Crafts Figurines Best Choice Products comes into play.FeaturesThe New Airbrush Spray Booth Kit Paint Craft Odor Extractor Hobby Crafts Figurines Best Choice Products is a complete kit that includes everything you need to set up your own spray booth. The most notable feature of this kit is the powerful fan that is included. The fan is designed to help remove harmful particles and fumes from the workspace quickly and efficiently. This helps to keep you safe while working and ensures that your finished products are of the highest quality.Another important feature of this kit is the fiberglass filter that is included. The filter effectively captures and removes harmful particles from the air, preventing them from being inhaled or settling on your finished work. This is a critical feature, particularly for those who work in enclosed spaces, as it helps to keep the air clean and breathable.BenefitsThere are many benefits to using a spray booth kit like the New Airbrush Spray Booth Kit Paint Craft Odor Extractor Hobby Crafts Figurines Best Choice Products. For starters, it helps to keep the air in your workspace clean and breathable. This is crucial, as many paints and chemicals used in airbrushing and other related hobbies can be harmful when inhaled in large quantities. By removing these particles from the air, spray booth kits help to keep you safe while you work.Another benefit of using a spray booth kit is that it helps to improve the quality of your finished work. By removing particles from the air, your work is less likely to be marred by impurities and other blemishes. This can make a huge difference, particularly for those who are working on items that need to be sold or displayed publicly.Additionally, spray booth kits are often much more energy-efficient than other methods of ventilation. This is because they are designed to be highly efficient and effective, making it possible to use less electricity while still achieving the desired result.UsesThe New Airbrush Spray Booth Kit Paint Craft Odor Extractor Hobby Crafts Figurines Best Choice Products is ideal for a wide range of applications. It is particularly useful for those who work with airbrushes and spray paints, as these methods can generate a lot of harmful particulates and fumes. However, it can also be used for other types of crafts and hobbies that involve potentially harmful chemicals or materials.ConclusionIn conclusion, the New Airbrush Spray Booth Kit Paint Craft Odor Extractor Hobby Crafts Figurines Best Choice Products is an excellent choice for anyone who wants to work safely and effectively in their chosen craft or hobby. It is easy to set up, highly efficient, energy-saving, and provides a host of benefits that are hard to ignore. Whether you are an experienced professional or just starting out, this spray booth kit is definitely worth considering. So why wait? Order your New Airbrush Spray Booth Kit Paint Craft Odor Extractor Hobby Crafts Figurines Best Choice Products today and take your craft or hobby to the next level!

New Underbody Coating System Offers Superior Protection for Vehicles

Underbody Coating System is a revolutionary new product that is set to change the way we protect our vehicles from corrosion and rust. Developed by a leading automotive company, this innovative system is designed to provide long-lasting protection for the underbody of vehicles, ensuring that they remain in top condition for years to come.The Underbody Coating System is a high-performance, abrasion-resistant coating that is applied to the undercarriage of vehicles. It effectively seals the metal surface, preventing the penetration of water, salt, and other corrosive substances that can cause rust and corrosion. This system is particularly beneficial for vehicles that are regularly exposed to harsh environments, such as off-road vehicles, trucks, and cars that are frequently driven in areas where road salt is used.This innovative product is also suitable for a wide range of vehicles, including passenger cars, commercial vehicles, and even heavy-duty machinery. It can be applied to both new and used vehicles, offering an extra layer of protection for owners who want to ensure the longevity of their vehicles.The application process is quick and efficient, with the coating able to be sprayed directly onto the undercarriage of the vehicle. Once applied, the coating dries quickly, forming a tough, durable barrier that is resistant to abrasion and impact. This means that vehicles treated with the Underbody Coating System are better equipped to withstand the rigors of everyday use, including the bumps and scrapes that come with off-road driving.The benefits of the Underbody Coating System are not only limited to protection against corrosion. The coating also has sound-deadening properties, reducing road noise and vibrations for a smoother, quieter ride. This makes it an ideal solution for those who want to improve the comfort and performance of their vehicles, as well as protecting them from the elements.Furthermore, the company behind the development of the Underbody Coating System has a long history of innovation and excellence in the automotive industry. With a strong commitment to quality and customer satisfaction, they have established themselves as a leading provider of automotive solutions, with a focus on cutting-edge technology and superior performance.The company’s dedication to research and development has led to the creation of the Underbody Coating System, which represents a significant advancement in vehicle protection. With a team of experienced engineers and technicians, they have been able to develop a product that meets the needs of modern drivers, offering a comprehensive solution for underbody protection.In addition to its technical expertise, the company is also committed to environmental sustainability, ensuring that its products are not only effective but also eco-friendly. This means that the Underbody Coating System not only protects vehicles from corrosion but also minimizes the impact on the environment, making it a responsible choice for conscientious consumers.Overall, the Underbody Coating System is set to revolutionize the way we protect our vehicles, offering a comprehensive and effective solution for underbody protection. With its innovative technology, durable performance, and commitment to sustainability, it represents a new standard in vehicle protection, providing peace of mind for drivers and ensuring that their vehicles remain in top condition for years to come.

Effective Spray Nozzles for Pretreatment Applications

Sustainable Manufacturing Solutions, a leading provider of industrial spray nozzles and systems, announced the launch of its new line of spray nozzles for pretreatment applications. These innovative nozzles are designed to provide efficient and effective surface preparation for a wide range of industrial processes, including coating, painting, and finishing.The new pretreatment spray nozzles feature cutting-edge technology and are engineered to deliver superior performance and durability. They are available in a variety of configurations to suit different pretreatment requirements, including cleaning, etching, and phosphating. The nozzles are also compatible with a wide range of chemicals and substrates, making them versatile and adaptable to various manufacturing environments."Sustainable Manufacturing Solutions is committed to developing advanced solutions that help our customers improve their manufacturing processes while reducing environmental impact," said the company's spokesperson. "Our new line of pretreatment spray nozzles is a testament to this commitment, as they are designed to deliver exceptional performance and reliability while enabling sustainable and efficient pretreatment processes."The new spray nozzles are constructed from high-quality materials and are designed to withstand the rigors of industrial applications. They are also easy to install and maintain, reducing downtime and maintenance costs for manufacturing facilities. In addition, the nozzles are precision-engineered to deliver consistent and uniform spray patterns, ensuring thorough and effective pretreatment of surfaces.In line with Sustainable Manufacturing Solutions' dedication to sustainability, the new pretreatment spray nozzles are also designed to minimize waste and energy consumption. They are engineered to maximize the use of pretreatment chemicals and reduce overspray, resulting in lower operating costs and environmental impact. The company also offers customization options for the nozzles, allowing customers to further optimize their pretreatment processes for sustainability and efficiency.The launch of the new pretreatment spray nozzles expands Sustainable Manufacturing Solutions' comprehensive portfolio of industrial spray solutions. The company has a proven track record of providing cutting-edge products and reliable services to a wide range of industries, including automotive, aerospace, metal fabrication, and general manufacturing. With a strong commitment to innovation and sustainability, Sustainable Manufacturing Solutions has established itself as a trusted partner for businesses seeking to improve their manufacturing processes and reduce their environmental footprint.In addition to its industry-leading products, Sustainable Manufacturing Solutions also offers expert technical support and consultation services to help customers optimize their pretreatment processes. The company's team of engineers and specialists can provide guidance on selecting the right pretreatment spray nozzles, as well as offer assistance in integrating them into existing manufacturing systems. This comprehensive approach ensures that customers can achieve the best possible results with Sustainable Manufacturing Solutions' spray nozzles.The introduction of the new pretreatment spray nozzles underscores Sustainable Manufacturing Solutions' commitment to driving innovation and sustainability in the manufacturing industry. By offering advanced, reliable, and sustainable solutions, the company continues to support its customers in achieving their operational and environmental goals. With a focus on performance, efficiency, and environmental responsibility, Sustainable Manufacturing Solutions is poised to remain a trusted partner for businesses seeking to enhance their manufacturing processes and reduce their environmental impact.

Effective Small Spray Booth for Your Business - Find Out More!

Small Spray Booths: A Game-Changer in the Automotive IndustryIn the automotive industry, one of the key aspects of delivering high-quality products is the application of paint on vehicles. As technology and innovation pave the way for a more efficient and effective means of painting vehicles, small spray booths have become a game-changer in the industry. These small spray booths, such as the one offered by {}, are revolutionizing the way automotive painting is done.{} has been a leading company in the automotive industry for over two decades, providing a wide range of products and services to meet the needs of their clients. With a strong commitment to innovation and quality, they have developed a small spray booth that is compact, efficient, and cost-effective. This small spray booth is designed to provide a high-quality finish while maximizing space and minimizing environmental impact.The small spray booth offered by {} is ideal for automotive workshops, small garages, and even individual hobbyists. Its compact size allows it to fit into tight spaces without sacrificing its functionality. With a focus on energy efficiency, this small spray booth is equipped with a state-of-the-art ventilation system that minimizes the release of harmful fumes into the environment.One of the key features of this small spray booth is its versatility. It can accommodate a wide range of vehicle sizes and shapes, allowing for a seamless painting process regardless of the vehicle being worked on. Additionally, it is equipped with advanced filtering technology that ensures a clean and contaminant-free environment for the painting process.Furthermore, the small spray booth is designed with user convenience in mind. It is easy to operate, and its intuitive controls make it accessible to both experienced professionals and beginners in the automotive industry. With its quick and easy installation, it can be integrated into existing workshops without the need for extensive modifications.In addition to its functionality, the small spray booth offered by {} is also a cost-effective solution for automotive painting needs. Its energy-efficient design helps reduce operating costs, while its durable construction ensures longevity and minimal maintenance requirements. This makes it an attractive investment for businesses looking to improve their painting processes without breaking the bank.The introduction of small spray booths in the automotive industry has been a significant milestone, offering a more streamlined and efficient approach to painting vehicles. With the innovation and dedication of companies like {}, these small spray booths have the potential to revolutionize the industry, setting new standards for quality and environmental responsibility.As the automotive industry continues to evolve, the demand for high-quality painting solutions will only grow. With the small spray booth offered by {}, businesses and individuals alike can elevate their painting processes to new heights, ensuring a superior finish for their vehicles. This innovative solution is poised to make a lasting impact on the automotive industry, improving efficiency, quality, and sustainability for years to come.