Waterfall Spray Booths: A Revolution in Spray Booth Technology

By:Admin

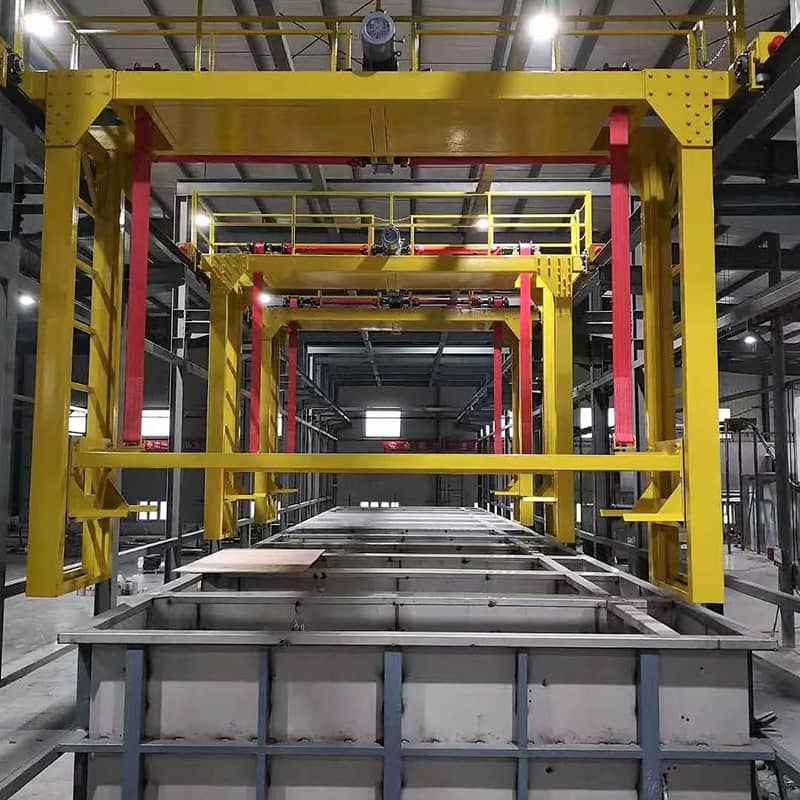

When it comes to industrial painting, efficiency, quality, and environmental impact are top priorities for companies. The use of advanced technology and innovative solutions has become increasingly important in achieving these goals. This is where the Waterfall Spray Booth comes into play, revolutionizing the way industrial painting is done.

The Waterfall Spray Booth, developed by a leading industrial equipment manufacturer, is a cutting-edge solution that offers a range of benefits for businesses in various industries. From automotive and aerospace to manufacturing and construction, this innovative spray booth is setting a new standard for paint technology.

One of the key features of the Waterfall Spray Booth is its unique design, which incorporates a cascading water system that captures overspray and eliminates harmful particles from the painting process. This not only ensures a cleaner and healthier working environment for employees but also reduces the environmental impact of industrial painting.

In addition to its environmental benefits, the Waterfall Spray Booth also offers unparalleled efficiency and quality in the painting process. The cascading water system helps to control overspray, resulting in a more precise and even application of paint. This, in turn, leads to a higher-quality finish and a reduction in the amount of paint used, ultimately saving businesses time and money.

Furthermore, the Waterfall Spray Booth is designed to be versatile and adaptable to the specific needs of each business. Whether it's the size of the booth, the type of paint being used, or the specific requirements of the application process, this innovative solution can be customized to fit any industrial painting operation.

Another aspect that sets the Waterfall Spray Booth apart is its ease of maintenance and cleaning. The cascading water system not only captures overspray but also helps to clean the booth itself, reducing the need for frequent and labor-intensive cleaning processes. This not only saves businesses time and money but also ensures that the booth is always operating at its best.

With the increasing emphasis on sustainability and environmental responsibility, the Waterfall Spray Booth has been receiving positive attention from businesses looking to improve their painting processes. Its innovative design and advanced technology are not only meeting the needs of today's industrial painting operations but also setting a new standard for the future.

"Here at {}, we are proud to introduce the Waterfall Spray Booth as the latest addition to our line of innovative industrial equipment," says the company's spokesperson. "We believe that this cutting-edge solution will revolutionize the way businesses approach industrial painting, offering a range of benefits for both the environment and their bottom line."

With its unprecedented efficiency, quality, and environmental impact, the Waterfall Spray Booth is proving to be a game-changer in the world of industrial painting. As more businesses seek to improve their processes and reduce their environmental footprint, this innovative solution is set to become an essential tool for the future of industrial painting.

Company News & Blog

10 popular decorative painting ideas to enhance any room

Decorative Painting Room, a leading provider of high-quality decorative painting services, is proud to announce the launch of their new line of unique and innovative designs. With a focus on craftsmanship and attention to detail, Decorative Painting Room is dedicated to helping their clients transform their living spaces into works of art.Specializing in custom decorative painting, Decorative Painting Room has established itself as a trusted name in the industry. Their team of skilled artisans and designers are committed to creating beautiful and visually stunning designs that enhance the aesthetic appeal of any room.“Our goal at Decorative Painting Room is to provide our clients with exceptional decorative painting services that truly elevate their living spaces,” said the company’s founder. “We believe that every room has the potential to be a work of art, and our team is dedicated to bringing our clients’ visions to life.”The company’s dedication to quality and craftsmanship is evident in their diverse portfolio of projects. From intricate murals and faux finishes to custom patterns and textures, Decorative Painting Room prides itself on its ability to create one-of-a-kind designs that cater to the unique tastes and preferences of their clients.In addition to their decorative painting services, Decorative Painting Room also offers a range of specialty finishes, including metallic paints, glazes, and plasters. These finishes are perfect for adding depth and richness to any surface, and can be customized to achieve a variety of different looks and textures.One of Decorative Painting Room’s most popular offerings is their custom mural painting service. Whether it’s a whimsical scene for a child’s bedroom or a sophisticated landscape for a dining room, the company’s team of talented artists can bring any vision to life with their expert painting skills.Beyond their commitment to craftsmanship, Decorative Painting Room also prioritizes customer satisfaction. From the initial design consultation to the final brushstroke, the company works closely with each client to ensure that their expectations are not only met, but exceeded.“We understand that every client has a unique vision for their space, and we take the time to listen and understand their needs,” said the founder. “Our goal is to provide an exceptional experience from start to finish, and to leave our clients with a space that they can truly be proud of.”With the launch of their new line of designs, Decorative Painting Room is poised to further solidify its position as a leader in the decorative painting industry. From contemporary and modern to traditional and timeless, the company’s new designs offer a diverse range of options to suit any style and taste.For those who are looking to elevate their living spaces with custom decorative painting, Decorative Painting Room provides a seamless and professional experience. With their dedication to quality, craftsmanship, and customer satisfaction, the company continues to set the standard for decorative painting services.Whether it’s a simple accent wall or a full room transformation, Decorative Painting Room is ready to bring their clients’ visions to life with their unparalleled expertise and artistry. With their new line of designs, the company is excited to continue serving as a trusted partner in helping clients turn their living spaces into stunning works of art.

Innovative System for Waste Water Treatment Shows Promising Results

Environmental protection is a critical issue in today's world, and one company is making a significant impact with its innovative UF system for wastewater treatment. This system is revolutionizing the way wastewater is treated, offering a more efficient and environmentally friendly solution.The UF system, developed by [company name], is a cutting-edge technology that utilizes ultrafiltration membranes to separate suspended solids, bacteria, and viruses from wastewater. This process results in cleaner, safer water that can be reused or safely discharged into the environment.With the growing concern over water scarcity and pollution, the need for effective wastewater treatment solutions has never been more critical. [Company name] is leading the charge with its UF system, providing a cost-effective and sustainable solution for various industries and municipalities.The UF system's compact design and modular configuration make it an ideal choice for both new and existing wastewater treatment facilities. It can be easily integrated into existing infrastructure, minimizing the need for costly and time-consuming upgrades.Notably, the UF system's superior performance and reliability have made it a preferred choice for many industrial and municipal wastewater treatment plants. It has proven to be highly effective in removing contaminants such as suspended solids, pathogens, and organic matter, ensuring that treated water meets the required quality standards.In addition to its exceptional performance, the UF system also offers significant operational benefits. Its automated operation and minimal maintenance requirements help reduce overall operating costs. Furthermore, the system's energy-efficient design contributes to lower energy consumption, making it a sustainable choice for wastewater treatment.One of the key advantages of [company name]'s UF system is its ability to provide a reliable and consistent treatment process, ensuring that the effluent meets stringent regulatory requirements. This is particularly important for industries that must adhere to strict environmental regulations and standards.Furthermore, the UF system's scalability allows for flexible capacity expansion, enabling plants to adapt to changing wastewater treatment demands. This feature is particularly valuable for industries with fluctuating production volumes or municipalities experiencing population growth.[Company name] takes great pride in its commitment to environmental stewardship and sustainability. The UF system is a reflection of this commitment, offering a solution that not only meets the needs of its customers but also contributes to a healthier and cleaner environment.In addition to its UF system, [company name] offers comprehensive support and services to ensure the successful implementation and operation of its wastewater treatment solutions. This includes technical assistance, training, and ongoing maintenance to optimize system performance and longevity.With its UF system for wastewater treatment, [company name] is helping industries and municipalities address the challenges of wastewater management while promoting environmental conservation and sustainability. Its innovative approach and dedication to excellence make it a leader in the field of wastewater treatment technologies.As the demand for sustainable wastewater treatment solutions continues to grow, [company name] remains at the forefront, driving innovation and setting new standards for performance, reliability, and environmental responsibility. With its UF system, the company is making a significant contribution to the preservation and responsible use of water resources, benefiting both present and future generations.

When it comes to painting, whether it's a small DIY project or a large painting job, the right spray gun can make all the difference. Spray guns are an essential tool for painting and can provide a smooth, even finish without the brush marks that come with traditional painting methods. In this blog, we will take a look at the benefits of using a spray can gun for your painting needs.Spray can guns are designed to provide a controlled and even spray pattern, which makes them an ideal tool for painting small or intricate surfaces. These guns are also useful for painting large surfaces, as they can cover a large area in a short amount of time. With the right spray can gun, you can achieve a professional-looking finish that is difficult to achieve with a brush or roller.One of the main benefits of using a spray can gun is that it saves time. Traditional painting methods can be time-consuming, particularly if you are painting a large area. With a spray can gun, you can cover a large area quickly and efficiently, which means you can move onto other projects or areas.Another benefit of using a spray can gun is that it saves you money. If you are painting a large area, such as a wall or ceiling, a spray can gun can help you to use less paint. This is because the gun provides a controlled spray pattern, which means you are less likely to overspray or waste paint. In addition, using a spray can gun can help you to avoid brush marks, which can be difficult to correct and may require you to use more paint.Using a spray can gun can also help you to achieve a more professional-looking finish. With a brush or roller, it can be difficult to achieve an even coating, particularly on textured surfaces. A spray can gun provides a smooth and even coat of paint, which can help to create a flawless finish.When choosing a spray can gun, there are a few things to consider. Firstly, you need to choose a gun that is suitable for the type of paint you are using. Some guns are specifically designed for use with latex paints, while others are better suited to oil-based paints. You also need to consider the size of the spray pattern that the gun provides. If you are painting a small area, you may want a gun that provides a narrow spray pattern, while for larger areas, you may need a wider spray pattern.In conclusion, using a spray can gun for your painting needs can help you to save time and money, achieve a more professional-looking finish, and avoid brush marks. When choosing a spray can gun, consider the type of paint you are using and the size of the spray pattern you require. With the right spray can gun, you can achieve a flawless finish that will make your painting project look amazing.

China's Leading Manufacturer Offers High-Quality Chain Conveyors for Various Applications

In today's fast-paced manufacturing industry, having a reliable and efficient material handling system is crucial for businesses of all sizes. One of the most widely used and trusted material handling solutions is the In-Floor Chain Conveyor. This conveyor system is ideal for transporting heavy loads over long distances, making it perfect for use in industrial settings.What Is an In-Floor Chain Conveyor?An In-Floor Chain Conveyor is a conveyor system that uses chains to transport heavy loads over long distances. It is designed to be installed flush with the factory floor, hence the name. The conveyor chain is usually made of steel and is driven by a motor that moves the chain along a track. The In-Floor Chain Conveyor can be used to transport a wide variety of materials, including boxes, pallets, and large industrial equipment.Advantages of In-Floor Chain ConveyorThere are several advantages to using an In-Floor Chain Conveyor. Firstly, it is an efficient and cost-effective material handling solution. This conveyor system is capable of carrying heavy loads over long distances, reducing the need for manual labor, and enabling fast and efficient movement of materials.Secondly, the In-Floor Chain Conveyor is an excellent space-saving solution. It is designed to be installed flush with the factory floor, freeing up valuable floor space for other equipment and activities. This system can also be customized to fit any factory layout, ensuring maximum efficiency and productivity.Thirdly, the In-Floor Chain Conveyor is a reliable and safe material handling solution. The chain is enclosed in a steel track, preventing any accidents or damage to the cargo. This system is also fully automated, reducing the risk of worker injury and ensuring consistent performance.Y&G Packing Machinery (Shanghai) Co., Ltd. - The Best In-Floor Chain Conveyor SupplierIf you are searching for a high-quality In-Floor Chain Conveyor for your manufacturing or industrial facility, look no further than Y&G Packing Machinery (Shanghai) Co., Ltd. Our company is a leading supplier of automated material handling solutions in China, offering a wide range of conveyor systems, filling machines, and sealing equipment.At Y&G Packing Machinery (Shanghai) Co., Ltd., we use only the best quality materials, components, and technology to manufacture our In-Floor Chain Conveyor. Our conveyor systems are designed to be durable, efficient, and reliable, ensuring maximum productivity and efficiency for your facility.Moreover, our In-Floor Chain Conveyor can be customized to fit your specific manufacturing needs. We offer a wide range of configuration options, including conveyor length, motor power, and load capacity. Additionally, our team of expert engineers can work with you to design a conveyor system that is tailored to your unique requirements.ConclusionIn conclusion, an In-Floor Chain Conveyor is an excellent material handling solution for any manufacturing or industrial facility. It is an efficient, space-saving, and reliable solution that can help improve productivity and reduce manual labor. If you are looking for a high-quality In-Floor Chain Conveyor supplier, look no further than Y&G Packing Machinery (Shanghai) Co., Ltd. Contact us today to learn more about our products and services.

Portable Temporary Spray Booth for Efficient Painting Projects

Introducing the latest innovation in automotive refinishing technology – the Temp Spray Booth. This cutting-edge spray booth is designed to meet the needs of auto body shops and professional refinishers who require a versatile, portable, and efficient solution for their painting and refinishing projects.The Temp Spray Booth is the brainchild of a leading manufacturer of automotive refinishing equipment {}. With over 20 years of experience in the industry, the company has earned a reputation for producing high-quality, reliable, and innovative products that meet the evolving needs of their customers. Their commitment to excellence and dedication to customer satisfaction have set them apart as a leader in the automotive refinishing industry.The Temp Spray Booth is no exception to their track record of excellence. This state-of-the-art portable spray booth is designed to provide a temporary, yet highly effective solution for automotive painting and refinishing projects. Its compact and lightweight design makes it easy to set up and transport, allowing users to bring the spray booth directly to the job site, whether it's a garage, workshop, or outdoor location. This unparalleled mobility offers a level of flexibility and convenience that traditional fixed spray booths simply cannot match.In addition to its portability, the Temp Spray Booth is equipped with a range of features that make it a powerful tool for automotive refinishers. Its advanced filtration system ensures that the surrounding environment remains free from overspray and contaminants, creating a safe and clean workspace for paint application. The booth's efficient ventilation system also helps to expedite drying times, allowing for faster turnaround on projects and increased productivity.Furthermore, the Temp Spray Booth is designed to accommodate a variety of painting and refinishing needs, offering customizable options for size, ventilation, and lighting. This flexibility makes it suitable for a wide range of applications, from small touch-up jobs to full-scale automotive repainting projects. With the ability to adjust the booth to specific project requirements, users can achieve professional results with ease and precision.The Temp Spray Booth also prioritizes energy efficiency, utilizing advanced technology to minimize power consumption without compromising performance. This eco-friendly design not only reduces operational costs, but also demonstrates a commitment to sustainability and environmental responsibility. Additionally, the booth's durable construction and high-quality materials ensure longevity and reliability, making it a sound investment for automotive refinishers seeking a long-term solution.As automotive refinishing professionals continue to seek out innovative tools and equipment to enhance their craft, the Temp Spray Booth stands out as a game-changing solution that delivers on performance, convenience, and quality. Its portability, versatility, and efficiency set a new standard for spray booth technology, offering a competitive edge to those in the industry who demand nothing less than the best.In conclusion, the Temp Spray Booth represents a significant leap forward in automotive refinishing technology, providing a portable, efficient, and high-performance solution for professional refinishers. With its innovative design, advanced features, and commitment to quality, it is poised to revolutionize the way automotive painting and refinishing projects are approached. As the automotive industry continues to evolve, the Temp Spray Booth stands as a testament to the ongoing innovation and dedication of its manufacturer, solidifying their position as a leader in the automotive refinishing market.

High-Quality Powder Coating Oven for LPG Use – A Complete Guide

Lpg Powder Coating Oven is a significant addition to the manufacturing capabilities of the company. This new equipment is a testament to the company's commitment to delivering high-quality products to its customers.The Lpg Powder Coating Oven is a state-of-the-art piece of machinery that will revolutionize the company's production process. This new oven is designed to provide a superior finish to the products, ensuring that they meet the highest quality standards. With the ability to coat a wide range of materials, this oven is versatile and can handle a variety of products.The company's decision to invest in the Lpg Powder Coating Oven demonstrates its dedication to staying ahead of the competition. By incorporating the latest technology into its manufacturing process, the company is ensuring that its products are of the highest quality and meet the demands of its customers.This new oven is equipped with advanced features that will streamline the company's production process and improve efficiency. Its precise temperature control and uniform heating capabilities will ensure that the products come out with a consistent and flawless finish every time. This will not only improve the overall quality of the company's products but also increase its production capacity.Furthermore, the Lpg Powder Coating Oven is designed with energy efficiency in mind. This will help the company reduce its operational costs while also minimizing its environmental impact. By using Lpg as a fuel source, the company is taking a step towards sustainable manufacturing practices.The company's investment in the Lpg Powder Coating Oven is also a testament to its commitment to excellence. By continuously upgrading its equipment and capabilities, the company is positioning itself as a leader in the industry. This will not only enhance its reputation but also attract new customers who are looking for high-quality products.In addition to the Lpg Powder Coating Oven, the company also offers a wide range of other services. These include custom fabrication, machining, and assembly. This comprehensive range of capabilities allows the company to provide end-to-end solutions to its customers, making it a one-stop shop for all their manufacturing needs.The company's dedication to customer satisfaction is evident in its commitment to quality and excellence. With the addition of the Lpg Powder Coating Oven, the company is furthering its ability to deliver the best products to its customers. This will help the company build long-lasting relationships with its clients and solidify its position as a trusted supplier.Furthermore, the company's team of skilled professionals is dedicated to ensuring that all products meet the highest standards. From design to manufacturing, the company's employees are committed to delivering excellence in every aspect of the production process. This attention to detail and quality is what sets the company apart from its competitors.In conclusion, the addition of the Lpg Powder Coating Oven to the company's manufacturing capabilities is a significant step forward. This new equipment will enable the company to deliver high-quality products with a superior finish, ensuring the satisfaction of its customers. With its commitment to excellence and dedication to quality, the company is well positioned to continue its success in the industry.

Enhancing Coating Techniques: Unraveling the Potential of Infrared Powder Coating

Title: Introducing Groundbreaking Infrared Powder Coating for Enhanced Efficiency and QualityIntroduction:Infrared Powder Coating, a pioneering technology developed by [Company Name], is revolutionizing the powder coating industry. By harnessing the power of infrared radiation, this innovative solution offers higher levels of efficiency, productivity, and quality. [Company Name] is proudly leading the way in this field, setting new standards and redefining the future of powder coating.Paragraph 1 (150 words):Powder coating has long been favored for its durability, eco-friendliness, and versatility. However, traditional powder coating methods have had their limitations when it comes to efficiency, requiring significant energy consumption and longer curing times. Recognizing this challenge, [Company Name] introduced Infrared Powder Coating as a game-changing solution.Infrared Powder Coating encompasses the use of advanced infrared radiation technology to optimize the curing process. Unlike traditional convection and radiant heating methods, infrared radiation directly heats the objects to be coated, resulting in faster and more uniform curing. This enables a substantial increase in production rates, reducing both energy consumption and production costs for businesses.Paragraph 2 (200 words):Underpinning the technological breakthrough of Infrared Powder Coating, [Company Name] has heavily invested in research and development, continuously enhancing the formulation of the powder material itself. The resulting powder formulation ensures compatibility with infrared radiation, enabling faster and more efficient curing while maintaining excellent adhesion and coating durability.A key advantage of Infrared Powder Coating is its ability to cure at lower temperatures. This not only saves energy but also reduces the risk of damage to heat-sensitive substrates. Furthermore, the precision control of the infrared radiation ensures full curing, eliminating the occurrence of undercured or overcured areas, which often leads to coating defects.By maximizing efficiency in the curing process, [Company Name]'s Infrared Powder Coating minimizes production time, enabling businesses to meet tight deadlines and increase overall capacity. Additionally, the reduction in energy consumption contributes to a greener workflow, aligning with sustainability goals and reducing the company's carbon footprint.Paragraph 3 (200 words):The benefits of Infrared Powder Coating are not limited to improved efficiency and reduced costs. The technology also enhances coating quality and consistency. The direct heating method of infrared radiation facilitates the effective flow and leveling of powder, resulting in smoother and more uniform coatings.Moreover, the precise temperature control offered by the infrared system allows for a broader range of coating applications, including heat-sensitive and delicate parts. [Company Name] ensures that their infrared systems are ergonomically designed, allowing easy integration into existing production lines and providing user-friendly operation features to streamline manufacturing processes.The versatility of Infrared Powder Coating extends to its applications across various industries, including automotive, consumer goods, electronics, and furniture. Putting customer satisfaction at the forefront, [Company Name] offers tailor-made solutions to meet the unique requirements of each industry, ensuring the achievement of impeccable finishes and long-lasting coatings.Conclusion (150 words):In conclusion, Infrared Powder Coating developed by [Company Name] represents a revolutionary advancement in the field of powder coating. By leveraging the power of infrared radiation technology, this innovative solution offers enhanced efficiency, reduced curing time, improved quality, and expanded application possibilities. Businesses can benefit from increased productivity, reduced energy consumption, and high-quality finishes that surpass traditional coating methods.As the industry leader, [Company Name] continues to push the boundaries of powder coating technology, contributing to a more sustainable and efficient manufacturing landscape. With their Infrared Powder Coating solutions, businesses can unlock new competitive advantages, achieve greater operational excellence, and deliver superior products to satisfy the demands of a dynamic market.

Discover the Benefits of an Efficient Oil Spray Booth for Industrial Operations

Title: Cutting-Edge Oil Spray Booth Revolutionizes Industrial Painting ProcessesIntroduction:In today's rapidly evolving industrial landscape, companies across various sectors are continually seeking ways to streamline and enhance their production processes. Addressing this need for efficiency and innovation, an industry-leading company has introduced its groundbreaking Oil Spray Booth, revolutionizing the way industrial painting is conducted. This cutting-edge technology promises to optimize paint application, reduce waste, and improve overall operational efficiency, making it a game-changer for manufacturing facilities worldwide.Paragraph 1:The newly developed Oil Spray Booth integrates state-of-the-art features, delivering unparalleled precision and control over the painting process. Equipped with advanced automation capabilities, the booth allows for precise adjustments of spray patterns, ensuring optimal coating thickness and even application. This breakthrough technology eliminates the challenges associated with manual painting techniques, providing a consistent and flawless finish on a wide range of surfaces.Paragraph 2:In addition to superior control, the Oil Spray Booth offers remarkable efficiency improvements. With its optimized airflow design, the booth effectively captures overspray, reducing waste and minimizing environmental impact. By preventing excessive paint usage, manufacturers can significantly cut down on material costs, ultimately boosting their bottom line. Moreover, the booth's automated cleaning system simplifies maintenance, reducing downtime and enabling uninterrupted production cycles.Paragraph 3:By adopting this innovative solution, manufacturing facilities can enhance workplace safety standards. The Oil Spray Booth's advanced filtration system efficiently captures hazardous particles, preventing their release into the environment. This feature not only ensures compliance with strict regulatory standards but also safeguards workers' health by reducing exposure to harmful substances. As a result, companies using this cutting-edge technology can create a safer and healthier working environment for their employees.Paragraph 4:The Oil Spray Booth's remarkable capabilities extend beyond the industrial painting realm, making it an incredibly versatile solution. Whether in the automotive, aerospace, woodworking, or construction industries, this technology provides a consistent and precise finish on various substrates. Its adaptability caters to the unique requirements of diverse industries, including both small-scale production facilities and large-scale manufacturing plants.Paragraph 5:To meet the evolving needs of their clients, the company behind this innovative solution has continuously invested in research and development. It has collaborated closely with industry experts to ensure their Oil Spray Booth remains at the cutting edge of technology, incorporating feedback and insights from manufacturers across different sectors. The result is a solution that addresses industry challenges, enables process optimization, and sets new benchmarks for quality and efficiency.Conclusion:In an era where optimization and efficiency are paramount, the introduction of the Oil Spray Booth marks a significant milestone in industrial painting. This innovative technology brings unparalleled control, efficiency, and safety to the painting process, catering to diverse industries' specific needs. By embracing this cutting-edge solution, manufacturers can seamlessly integrate an advanced and sustainable approach to painting into their operations, resulting in improved quality, reduced wastage, and increased profitability.

Windsor Assembly Plant Wins Energy Project of the Year for Topcoat Booth Optimization

Title: Optimizing Topcoat Paint Booth at Windsor Assembly Plant: A Sustainable Energy Project Recognized by AEEIntroduction:In a commendable achievement, Stellantis' Windsor Assembly Plant (WAP) has been recognized by the Association of Energy Engineers (AEE) for its outstanding efforts in energy optimization. The plant's topcoat observation booth downdraft optimization project has earned the prestigious 2021 Canada Region Energy Project of the Year award. This blog post will delve into the project's details, emphasizing the reduction in energy usage within WAP's paint shop and its significant implications for sustainable development. Additionally, we will discuss how the project's success aligns with the keywords 'topcoat paint booth' and its relevance within the industry.Energy Optimization for Sustainable Development:The mission of the Association of Energy Engineers (AEE) aligns perfectly with the objectives of the topcoat observation booth downdraft optimization project at Windsor Assembly Plant. Pursuing sustainable development is crucial, especially in energy-intensive industries like automotive manufacturing. By promoting scientific and educational interests and fostering actionable projects, AEE aims to drive sustainability measures within the energy industry. WAP's recognition signifies a significant step towards reducing energy consumption and its associated carbon footprint.Overview of the Winning Project:The winning project at Windsor Assembly Plant focused on optimizing the topcoat observation booth downdraft system in the paint shop, aiming to maximize efficiency and minimize energy usage. In total, the project successfully reduced energy consumption by an impressive amount of 20,250 gigajoules (GJ), which translates to an 8% annual reduction in the topcoat process. To comprehend the scale of this achievement, one can consider the electricity used in nearly 490 homes within a single year.Keywords: Topcoat Paint Booth and Its Significance:The keywords 'topcoat paint booth' hold substantial significance within the automotive manufacturing industry. As a crucial stage in the vehicle production process, the topcoat application plays a vital role in ensuring a vehicle's appearance, protection, and durability. Considering the immense energy requirements and potential environmental impact that can accompany this process, optimizing the topcoat paint booth becomes imperative.The project's scope encompassed the entire topcoat observation booth downdraft system, which is responsible for maintaining a controlled environment during the application of the paint. By enhancing efficiency in this area, WAP achieved remarkable energy savings and consequent sustainability benefits.Energy Savings and Environmental Impact:The reduction of energy usage by 20,250 GJ annually in WAP's paint shop represents a significant achievement for sustainability. Beyond the sheer figures, it is crucial to understand the environmental impact of such energy savings. The reduction is equivalent to the electricity consumption of 490 homes in a year. This commendable achievement not only showcases WAP's commitment to energy efficiency but also highlights the enormous potential the automotive industry holds in contributing to a greener future.Implications for Sustainable Manufacturing:The optimization project at Windsor Assembly Plant sets a remarkable precedent for other manufacturing facilities within the industry. By prioritizing energy efficiency and sustainability, WAP not only reduces its carbon footprint but also establishes a roadmap for sustainable manufacturing practices. Collaboration between automakers, energy engineers, and relevant professionals can lead to revolutionary projects that contribute to lasting environmental benefits.Conclusion:In the wake of achieving the 2021 Canada Region Energy Project of the Year award, Stellantis' Windsor Assembly Plant should be commended for its dedication to sustainability and energy efficiency. Through the optimization of the topcoat observation booth downdraft system in their paint shop, the plant has successfully reduced energy consumption by an impressive amount, equivalent to the electricity used in 490 homes in one year. This accomplishment highlights the potential for sustainable development within the automotive industry and sets an example for other manufacturing facilities to follow. With continued collaborative efforts and targeted projects, the industry can pave the way for a greener and more sustainable future.

Top Medium Velocity Water Spray Nozzle for Industrial Use

Medium Velocity Water Spray Nozzles have long been a crucial component in fire protection systems, providing efficient and effective fire suppression in a variety of environments. These nozzles are specifically designed to deliver a medium velocity water spray pattern, which is ideal for controlling and extinguishing fires in applications such as industrial facilities, heavy manufacturing plants, and storage areas.One company that has been at the forefront of manufacturing and supplying high-quality Medium Velocity Water Spray Nozzles is {Company Name}. With a strong focus on innovation, reliability, and customer satisfaction, {Company Name} has been a trusted name in the fire protection industry for many years. Their commitment to providing cutting-edge solutions for fire suppression has earned them a reputation as a leading provider of fire protection products and services.{Company Name} has a rich history of producing top-of-the-line Medium Velocity Water Spray Nozzles that are designed to meet the highest standards of quality and performance. Their team of engineers and technicians work tirelessly to develop innovative nozzle designs that are efficient, durable, and easy to install. The company's dedication to research and development has allowed them to stay ahead of the curve in a constantly evolving industry.In addition to their commitment to producing high-quality products, {Company Name} also places a strong emphasis on customer service and support. They understand that every fire protection system is unique, and they work closely with their clients to provide customized solutions that meet their specific needs and requirements. Whether it's designing a new system or retrofitting an existing one, {Company Name} is dedicated to delivering tailored solutions that ensure maximum protection and peace of mind.{Company Name} is also known for their comprehensive range of services, including installation, maintenance, and inspection of fire protection systems. Their team of highly trained technicians is equipped with the knowledge and expertise to handle any project, no matter how big or small. With a focus on safety and compliance, {Company Name} is committed to ensuring that their clients' fire protection systems are always in top working condition, providing the ultimate level of protection in the event of a fire emergency.The Medium Velocity Water Spray Nozzles offered by {Company Name} are not only designed to meet industry standards, but they also incorporate the latest advancements in technology and engineering. This ensures that their products are highly efficient and reliable, delivering superior performance when it matters most. With a dedication to continuous improvement, {Company Name} continuously strives to develop new technologies and designs that push the boundaries of fire protection, setting new standards for the industry.As a company that places a strong emphasis on environmental sustainability, {Company Name} is also committed to developing fire protection solutions that are eco-friendly and energy-efficient. They understand the importance of minimizing the environmental impact of their products, and they work tirelessly to integrate green practices into their manufacturing processes. By offering environmentally conscious solutions, {Company Name} is not only protecting their clients from fire risk, but also demonstrating their commitment to protecting the planet for future generations.In conclusion, {Company Name} has established itself as a leading provider of Medium Velocity Water Spray Nozzles, delivering top-quality products and services that meet the highest industry standards. With a focus on innovation, reliability, and customer satisfaction, {Company Name} continues to be a trusted partner for businesses in need of effective fire protection solutions. As they continue to push the boundaries of technology and engineering, {Company Name} remains at the forefront of the fire protection industry, setting new benchmarks for excellence and performance.