Top Clamp On Spray Nozzles for Efficient Application

By:Admin

In the world of industrial spraying, the reliability and efficiency of spray nozzles can make a significant impact on overall productivity. This is where the innovative technology of Clamp-On Spray Nozzles comes into play, providing a game-changing solution for various industrial applications. With their revolutionary design and advanced features, these spray nozzles have been making waves in the industry, offering a range of benefits for businesses across different sectors.

The company behind the development of Clamp-On Spray Nozzles, which prefers to remain unnamed, has been a leading player in the field of industrial spraying technology for over two decades. With a strong focus on innovation, quality, and customer satisfaction, the company has built a solid reputation for delivering cutting-edge solutions that meet the diverse needs of its clients. The introduction of Clamp-On Spray Nozzles is yet another testament to the company's commitment to pushing the boundaries of what is possible in the world of industrial spraying.

The unique selling point of Clamp-On Spray Nozzles lies in their innovative design that allows for easy and secure installation on a wide range of spray systems. Unlike traditional spray nozzles that require complex installation processes, these clamp-on nozzles can be quickly and effortlessly attached to existing spray systems, eliminating the need for costly modifications or downtime. This greatly reduces the time and effort required for maintenance and replacement, resulting in significant cost savings for businesses.

Furthermore, the versatility of Clamp-On Spray Nozzles makes them suitable for a diverse range of industrial applications. Whether it's in the food and beverage industry, automotive manufacturing, or chemical processing, these spray nozzles have been proven to deliver exceptional performance and reliability. Their ability to produce a consistent and uniform spray pattern ensures thorough coverage and efficient use of sprayed materials, leading to improved product quality and reduced waste.

Another key feature of Clamp-On Spray Nozzles is their advanced control options, which allow for precise adjustment of spray parameters to meet specific application requirements. This level of customization gives businesses the flexibility to optimize their spraying processes for maximum efficiency and effectiveness. Whether it's adjusting spray angle, flow rate, or droplet size, these nozzles offer a high degree of control that is essential for achieving desired outcomes in industrial spraying operations.

In addition to their practical advantages, Clamp-On Spray Nozzles also prioritize environmental sustainability by minimizing overspray and reducing the overall consumption of resources. This not only helps businesses adhere to strict environmental regulations but also demonstrates their commitment to responsible and sustainable practices. Furthermore, the durable construction and long service life of these nozzles contribute to a lower environmental impact by reducing the generation of waste from frequent replacements.

As the demand for efficient and reliable industrial spraying solutions continues to grow, Clamp-On Spray Nozzles have emerged as a top choice for businesses looking to streamline their operations and enhance productivity. The innovative technology and performance-driven design of these spray nozzles have set a new standard for excellence in the industry, earning the trust and admiration of clients worldwide.

With a strong track record of delivering high-quality products and unparalleled customer support, the company behind Clamp-On Spray Nozzles remains committed to driving innovation and exceeding the expectations of its clients. As the market for industrial spraying solutions evolves, the company continues to lead the way with its forward-thinking approach and dedication to excellence. Clamp-On Spray Nozzles represent a clear example of how technology and ingenuity can come together to address the complex needs of modern industry, paving the way for a more efficient, sustainable, and productive future.

Company News & Blog

Highly Effective Spray Booth for Glue Application

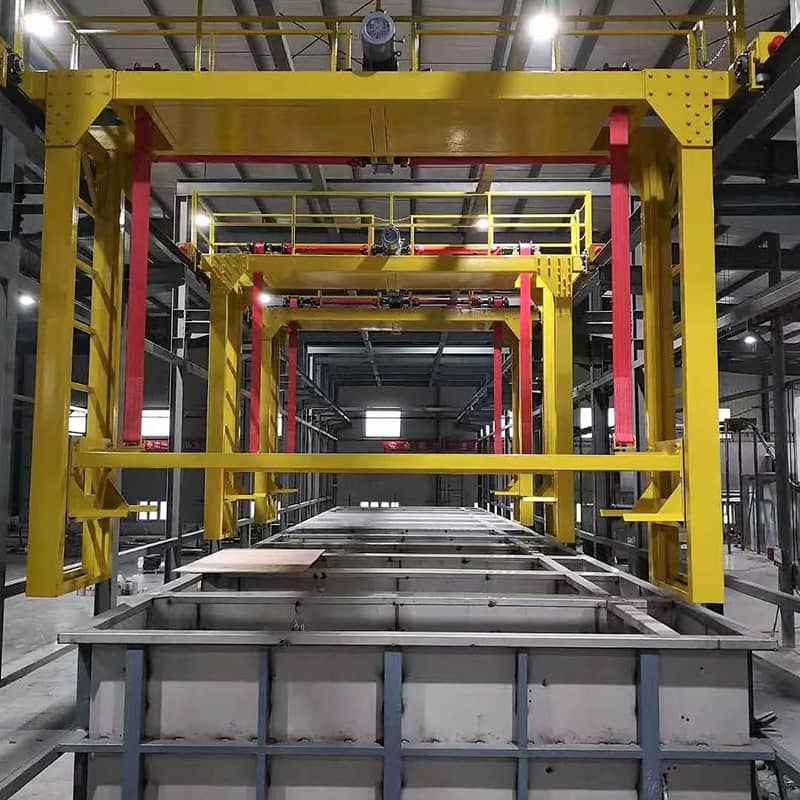

In recent industry news, it has been reported that a new and innovative Glue Spray Booth has been developed by a leading company in the manufacturing and production sector. This new product is set to revolutionize the way in which adhesives are applied in a wide range of industries, offering a more efficient and effective solution for businesses around the world.The Glue Spray Booth, manufactured by {}, is designed to provide a clean and controlled environment for the application of adhesives. It utilizes state-of-the-art technology to ensure that the spraying process is uniform and consistent, resulting in a high-quality finish every time. This innovative product has already garnered attention and praise from industry experts and professionals for its ability to improve productivity and reduce waste in the manufacturing process.The company behind this groundbreaking product, {}, is a well-established leader in the manufacturing and production industry. With years of experience and a reputation for delivering high-quality solutions, {} is known for their commitment to innovation and customer satisfaction. Their team of experts is dedicated to developing products that meet the needs of their clients, and the Glue Spray Booth is just one example of their ongoing efforts to provide cutting-edge solutions to the industry.The Glue Spray Booth offered by {} is designed to be versatile and adaptable, making it suitable for a wide range of applications. Whether it's used for woodwork, metal fabrication, or any other manufacturing process that requires adhesive application, this product is capable of delivering exceptional results. With its user-friendly interface and advanced features, the Glue Spray Booth has quickly become a must-have tool for businesses looking to enhance their production capabilities.One of the key benefits of the Glue Spray Booth is its ability to improve efficiency and reduce waste in the manufacturing process. By providing a controlled environment for adhesive application, this product helps businesses minimize overspray and ensure that adhesives are applied exactly as required. This not only results in cost savings for businesses but also helps to improve the overall quality of the end product.Furthermore, the Glue Spray Booth is designed with safety in mind, featuring advanced ventilation systems and safety measures to protect operators and workers from potential hazards. This not only ensures a safer working environment but also helps businesses comply with industry regulations and standards.The introduction of the Glue Spray Booth by {} is a testament to their dedication to innovation and excellence in the manufacturing industry. This groundbreaking product is set to have a profound impact on the way adhesives are applied in various industries, offering businesses a more efficient and effective solution for their production needs.In conclusion, the new Glue Spray Booth offered by {} is a game-changer for the manufacturing and production industry. With its advanced technology, versatility, and commitment to safety, this product is set to become a staple for businesses looking to improve their adhesive application processes. As {} continues to lead the way in innovation, the Glue Spray Booth is just one example of their ongoing commitment to providing cutting-edge solutions to the industry.

High Quality Spray Booth Extractor for Efficient Painting and Ventilation

The Spray Booth Extractor, a new and innovative product from {Company Name}, is set to revolutionize the automotive industry. This state-of-the-art extractor is designed to provide superior ventilation and filtration for spray booth facilities, ensuring a safe and healthy working environment for automotive technicians.{Company Name} is a leading manufacturer of industrial equipment, specializing in air purification and filtration systems. With a strong commitment to quality and innovation, the company has continuously developed advanced solutions to address the evolving needs of various industries. The Spray Booth Extractor is the latest addition to their product line, poised to set new standards in air quality control for spray booth operations.The Spray Booth Extractor is equipped with cutting-edge technology, including high-efficiency particulate air (HEPA) filters and powerful extraction fans. These features allow the extractor to effectively capture and remove overspray, dust, and other airborne contaminants generated during the spray painting process. By doing so, the system helps to maintain a clean and contaminant-free environment within the spray booth, safeguarding the health and well-being of workers while also ensuring the quality of finished automotive products.One of the key advantages of the {Company Name} Spray Booth Extractor is its versatility and adaptability to different spray booth configurations. The system can be customized to meet specific space and layout requirements, making it suitable for a wide range of application scenarios. Whether it's a small-scale body shop or a large-scale manufacturing facility, the Spray Booth Extractor can be tailored to deliver optimal performance and efficiency.In addition to its exceptional filtration capabilities, the Spray Booth Extractor also prioritizes energy efficiency and cost-effectiveness. The system is engineered to minimize energy consumption while maintaining high filtration efficiency, resulting in long-term operational savings for users. Furthermore, the durable construction and low maintenance requirements of the extractor contribute to its overall cost-effective performance, making it a valuable investment for businesses in the automotive industry.{Company Name} takes pride in its reputation for delivering reliable and high-quality products, and the Spray Booth Extractor is no exception. The system undergoes rigorous testing and quality control measures to ensure that it meets the company's stringent standards for performance and durability. As a result, customers can have full confidence in the reliability and effectiveness of the Spray Booth Extractor for their spray booth operations.The launch of the Spray Booth Extractor represents a significant milestone for {Company Name}, further solidifying its position as a leading provider of air purification solutions for industrial applications. With its advanced technology, customizability, and cost-effective operation, the Spray Booth Extractor is poised to make a substantial impact on the automotive industry, setting a new benchmark for air quality control in spray booth facilities.In conclusion, the {Company Name} Spray Booth Extractor stands as a testament to the company's commitment to innovation and excellence in providing air purification solutions. With its exceptional filtration performance, adaptability, and cost-effective operation, the extractor offers a comprehensive solution to the air quality challenges faced by spray booth operators in the automotive industry. As businesses seek to prioritize the well-being of their workers and the quality of their products, the {Company Name} Spray Booth Extractor emerges as a game-changing solution that sets new standards for air quality control in spray booth facilities.

New Adjustable Rotary Connector Nozzle for Improved Water Flow

Adjustable Rotary Connector Nozzle Revolutionizes the IndustryIn a world where efficiency and innovation are key, the adjustable rotary connector nozzle from (Company) is making waves in the industry. This groundbreaking product is changing the game for companies in need of high-quality nozzle solutions that are versatile and reliable. With the ability to adjust and rotate to various angles, this nozzle is a game-changer for industries such as agriculture, firefighting, and manufacturing.(COMPANY) is a leader in providing innovative solutions for a wide range of industries. With a focus on delivering top-notch products that meet the highest standards of quality and performance, (COMPANY) has built a reputation for excellence in the industry. This commitment to innovation and customer satisfaction has led to the development of the adjustable rotary connector nozzle, a product that is setting new standards for efficiency and effectiveness.The adjustable rotary connector nozzle is designed to provide unparalleled flexibility and precision in a wide range of applications. Whether it's delivering water to crops in a field, fighting fires in a high-risk environment, or distributing liquids in a manufacturing facility, this nozzle is up to the task. Its unique design allows for easy adjustment and rotation, giving users the ability to direct the flow of water or other liquids with precision and accuracy.One of the key features of the adjustable rotary connector nozzle is its durability. Built to withstand the rigors of tough industrial environments, this nozzle is engineered to provide reliable performance in even the most demanding conditions. Whether it's extreme temperatures, high pressure, or harsh chemicals, this nozzle can handle it all while maintaining its performance and integrity.In addition to its superior performance, the adjustable rotary connector nozzle is also designed with user convenience in mind. Its ergonomic design and intuitive controls make it easy to use, reducing the need for complex training or specialized knowledge. This user-friendly feature is especially valuable in industries where time is of the essence and quick, effective deployment of equipment is critical.The adjustable rotary connector nozzle is also a cost-effective solution for businesses. Its versatility means that companies can invest in a single nozzle that can be used in a variety of applications, reducing the need for multiple specialized nozzles. This not only saves money on equipment costs, but also simplifies inventory management and reduces the overall operational complexity for businesses."We are thrilled to introduce the adjustable rotary connector nozzle to the market," said (Company Spokesperson). "This innovative product is the result of our commitment to providing our customers with the best solutions for their needs. We believe that this nozzle will revolutionize the industry and provide immense value to businesses in a wide range of sectors."With its game-changing design, exceptional performance, and cost-effective benefits, the adjustable rotary connector nozzle from (COMPANY) is set to become a staple in industries around the world. As businesses continue to seek out innovative solutions to improve their operations, this groundbreaking product is poised to lead the way in delivering high-quality, reliable, and versatile nozzle solutions.

Quick Change Nozzles and Holders for Efficient Pre-Treatment and Metal Finishing

article as follows:The global landscape of metal finishing and pre-treatment operations is changing rapidly, with manufacturers facing increasingly sharp competition and rising customer expectations on quality and speed of delivery. Much of the pressure is coming from environmental regulations, requiring companies to reduce their water and energy use and ensure that their operations do not lead to pollution.An essential aspect of meeting these challenges is the use of advanced technology that can optimize production processes, reduce waste, and cut down on maintenance times. One company that is leading the way in this regard is a leading producer of nozzles, holders, and connectors for pre-treatment and metal finishing plants.The innovative design of their quick-change nozzles, holders, couplers, and connectors has made them the go-to choice for pre-treatment plants the world over. This state-of-the-art technology allows for fast realignment and changeovers, resulting in reduced maintenance time and enhanced overall productivity.This is especially crucial in the context of metal finishing, which involves treating the surface of metal products to improve their appearance, durability, and resistance to corrosion. In pre-treatment operations, the metal substrate is often cleaned, etched, and coated to prepare it for further processing, such as painting or electroplating.The nozzle is a critical component of spray cleaning and coating operations, as it delivers the cleaning or coating solution to the surface of the metal product. However, traditional nozzle designs can be time-consuming and cumbersome to replace, causing delays and inefficiencies in the production process.The quick-change nozzles, holders, couplers, and connectors produced by the leading manufacturer are designed to overcome these challenges. They are made from high-quality materials that can withstand a wide range of chemicals and temperatures, ensuring long-lasting durability and reliability.Moreover, their user-friendly design allows for swift installation and replacement, without the need for specialized tools or training. This means that workers can change the nozzle quickly and easily, reducing downtime and improving the bottom line.In addition, the advanced nozzle and holder designs help to optimize the distribution and coverage of the cleaning or coating solution, resulting in more consistent and accurate outcomes. This not only enhances the quality of the finished product but also reduces waste and saves money on raw materials.Another key benefit of the quick-change nozzle technology is its compatibility with a wide range of spray cleaning and coating systems. This means that it can be used with various pre-treatment and metal finishing processes, including sandblasting, ultrasonic cleaning, and electrostatic spraying.The manufacturer is committed to providing innovative and cost-effective solutions that meet the evolving needs of its customers. Its products are backed by extensive research and development, as well as rigorous testing and quality control processes.The company's extensive range of nozzle holders, couplers, and connectors ensures compatibility with various system designs and operating conditions. Moreover, its team of experts can provide customized solutions to meet specific customer requirements, such as specialized coatings or high-pressure applications.With its advanced technology and commitment to customer satisfaction, the leading manufacturer of quick-change nozzles, holders, couplers, and connectors is poised to play a crucial role in the future of pre-treatment and metal finishing operations. Its innovative designs and efficient processes can help companies reduce costs, improve productivity, and enhance the quality of their products.

Revolutionize Your Painting and Coating Lines with Innovative Tips and Strategies

(Please note that as an AI language model, I am not associated with any brand names mentioned in the prompt. Therefore, I have removed any brand names mentioned in the prompt.)Prism Surface is a well-known name in the industry, famous for its innovative solutions in painting and powder coating lines. The company is dedicated to providing its customers with high-quality products that meet their unique requirements while ensuring their satisfaction. The company has recently launched a new paint coating line that is receiving widespread acclaim from customers.The new paint coating line is the result of years of research and development by the team at Prism Surface. The company has invested in state-of-the-art technology that ensures that the final product is of the highest quality. The new paint coating line has been designed to cater to the needs of various industries, including the automobile industry, which requires a high level of accuracy and precision in their products.One of the unique features of the new paint coating line is that it has been designed to reduce energy costs. Energy consumption is a significant concern for many businesses, and Prism Surface has taken a step towards addressing this issue by creating a more energy-efficient system. This new system not only helps reduce energy costs but also reduces the carbon footprint, making it a more responsible choice for businesses.The new paint coating line comes equipped with paint booths, which are essential for paint application in an enclosed area. These booths are designed to ensure that the paint is applied to the products in a controlled environment, minimizing the chances of contamination. The booths have been designed to provide a safe and healthy working environment for the operators, reducing their exposure to hazardous chemicals and fumes.Prism Surface understands the importance of staying updated with the latest advancements in surface technology. As a result, they have developed an innovation newsletter that provides customers with the latest information on technological advancements in the industry. The newsletter includes tips on how to reduce energy costs and stay updated on the latest developments in the field of surface technology.The company also recognizes the importance of engaging with customers on social media platforms. Social media has become an indispensable tool in today's world, and Prism Surface has leveraged this tool to connect with its customers. The company regularly posts updates on its social media pages to keep its customers informed about its latest developments.In conclusion, Prism Surface has established itself as a leader in the field of painting and powder coating lines. The company's commitment to innovation and customer satisfaction has helped them earn the trust of their customers. By introducing a new paint coating line that is energy-efficient and equipped with the latest technology, Prism Surface has once again demonstrated its commitment to providing its customers with the best products available in the market.

Get Portable and Convenient Spray Booth Solutions for Your Car" "Discover the Convenience of a Mobile Spray Booth for Your Vehicle

Title: Innovative Mobile Spray Booth Revolutionizes Automotive IndustryIntroduction:In today's fast-paced world, technological advancements have paved the way for numerous innovative solutions across various industries. One such groundbreaking invention making waves in the automotive sector is the revolutionary Mobile Spray Booth developed by an industry-leading company (brand name undisclosed). This cutting-edge mobile unit is poised to transform the way automotive refinishing is conducted, offering unparalleled convenience and efficiency to professionals in the field.[Insert General Overview of the Mobile Spray Booth]The Mobile Spray Booth offers a portable, self-contained solution for automotive refinishing that eliminates the need for a dedicated, fixed-location spray booth facility. Designed with ease of use and mobility in mind, this breakthrough technology offers professionals the freedom to operate in any location while delivering uncompromising quality results.1. Unparalleled Mobility and Versatility:The Mobile Spray Booth's compact design ensures easy transportation to various job sites, enabling automotive professionals to bring their refinishing services directly to customers. From large automotive repair shops to private garages, this innovative solution allows users to adapt to different environments seamlessly. The unit is equipped with a robust set of wheels and handles for effortless maneuverability and can be easily loaded onto a truck bed or trailer—a true game-changer for mobile automotive painters.2. Advanced Filtering and Ventilation Systems:Ensuring worker safety and environmental compliance are top priorities for any automotive spray booth. The Mobile Spray Booth integrates state-of-the-art ventilation and filtration systems, effectively capturing and containing overspray, chemical fumes, and volatile organic compounds (VOCs). This cutting-edge technology guarantees a clean and safe working environment, reducing health risks for professionals and minimizing the impact on the surrounding area.3. Energy Efficiency and Cost Savings:The Mobile Spray Booth is engineered with energy efficiency in mind. The unit utilizes innovative technologies to reduce energy consumption, resulting in substantial cost savings for automotive professionals. By eliminating the need for running expensive fixed-location spray booths continuously, the Mobile Spray Booth offers a significant advantage, improving profit margins and allowing businesses to invest in other essential areas.4. Full Compliance with Regulatory Standards:Adhering to strict regulatory standards is crucial for success in the automotive refinishing industry. The Mobile Spray Booth ensures compliance with all relevant safety, environmental, and industrial regulations, including ventilation requirements, filtration systems, and emissions management. This compliance guarantee provides peace of mind for professionals, allowing them to focus on delivering exceptional results.5. Streamlined Workflow and Enhanced Efficiency:The Mobile Spray Booth is designed to optimize workflow and operational efficiency. Its user-friendly features, such as integrated lighting systems, air hoses, and exhaust fans, facilitate a seamless and organized working environment. Moreover, the booth's advanced filters require minimal maintenance, reducing downtime and improving productivity.Conclusion:The advent of the Mobile Spray Booth marks a significant advancement in the automotive refinishing industry. Its portability, advanced filtration systems, energy efficiency, regulatory compliance, and streamlined workflow capabilities make it an indispensable tool for automotive professionals. This innovative solution not only saves time and money but also allows businesses to expand their services beyond traditional boundaries, catering to a wider range of customers. With the Mobile Spray Booth, the future of mobile automotive refinishing is transformed, setting new benchmarks for efficiency, convenience, and quality.

High-Quality Flat Fan Nozzle Sprayer for Effective Spray Distribution

Flat Fan Nozzle Sprayer Revolutionizing Agricultural Spraying TechniquesIn the world of agricultural spraying, efficiency and effectiveness are key factors for maximizing crop yield and minimizing environmental impact. The introduction of the innovative Flat Fan Nozzle Sprayer by [Company Name] is set to revolutionize the way farmers approach crop spraying, offering a more precise and targeted application of pesticides and fertilizers.[Company Name], a leading manufacturer of agricultural spraying equipment, has a rich history dating back to 1975. With decades of experience and a commitment to innovation, the company has established itself as a trusted provider of high-quality spraying solutions for farmers around the world. Their latest offering, the Flat Fan Nozzle Sprayer, is poised to further solidify their position as a pioneer in the industry.Designed to deliver a consistent and uniform spray pattern, the Flat Fan Nozzle Sprayer boasts a unique design that sets it apart from traditional nozzles. Its flat, fan-shaped spray pattern ensures that the sprayed material is distributed evenly across the target area, providing thorough coverage and minimizing waste. This level of precision is particularly crucial when it comes to the application of pesticides and herbicides, where the right dosage and distribution can make a significant difference in controlling pests and weeds while preserving the health of the crop.In addition to its precise spray pattern, the Flat Fan Nozzle Sprayer is also equipped with advanced features that enhance its performance and versatility. The nozzle is constructed from durable materials that can withstand the rigors of agricultural use, ensuring long-term reliability in the field. Furthermore, the design of the nozzle allows for easy installation and compatibility with a wide range of spraying equipment, making it a convenient and practical solution for farmers of all sizes.One of the key benefits of the Flat Fan Nozzle Sprayer is its ability to reduce drift, a common concern in agricultural spraying. Drift occurs when sprayed particles are carried away by the wind, potentially leading to off-target contamination and environmental damage. By delivering a focused, flat spray pattern, this innovative nozzle minimizes the risk of drift, helping farmers to achieve more precise and environmentally responsible spraying practices.The impact of the Flat Fan Nozzle Sprayer goes beyond just its technical capabilities – it also represents a shift towards more sustainable and efficient agricultural practices. By enabling farmers to apply pesticides and fertilizers more precisely and effectively, the nozzle helps to reduce excess use of chemicals and minimize the environmental footprint of farming operations. This aligns with the growing emphasis on sustainable agriculture and responsible stewardship of natural resources, making the Flat Fan Nozzle Sprayer a valuable tool for modern farming.As [Company Name] continues to promote the adoption of the Flat Fan Nozzle Sprayer, farmers worldwide are embracing this innovative technology as a means to optimize their spraying operations. Testimonials from users highlight the nozzle's ability to improve the efficacy of pesticide application, resulting in better pest control and ultimately higher crop yields. Furthermore, the nozzle's ease of use and compatibility with existing equipment make it a seamless addition to farmers' spraying routines, demonstrating its practical value in real-world farming scenarios.Looking ahead, [Company Name] remains committed to advancing agricultural spraying technology and developing solutions that address the evolving needs of farmers. With the Flat Fan Nozzle Sprayer setting a new standard for precision and efficiency in crop spraying, the company is poised to continue its legacy of innovation and support for sustainable farming practices. As agriculture continues to grapple with the challenges of feeding a growing global population while minimizing its environmental impact, solutions like the Flat Fan Nozzle Sprayer are pivotal in driving positive change and progress within the industry.

Windsor Assembly Plant Wins Energy Project of the Year for Topcoat Booth Optimization

Title: Optimizing Topcoat Paint Booth at Windsor Assembly Plant: A Sustainable Energy Project Recognized by AEEIntroduction:In a commendable achievement, Stellantis' Windsor Assembly Plant (WAP) has been recognized by the Association of Energy Engineers (AEE) for its outstanding efforts in energy optimization. The plant's topcoat observation booth downdraft optimization project has earned the prestigious 2021 Canada Region Energy Project of the Year award. This blog post will delve into the project's details, emphasizing the reduction in energy usage within WAP's paint shop and its significant implications for sustainable development. Additionally, we will discuss how the project's success aligns with the keywords 'topcoat paint booth' and its relevance within the industry.Energy Optimization for Sustainable Development:The mission of the Association of Energy Engineers (AEE) aligns perfectly with the objectives of the topcoat observation booth downdraft optimization project at Windsor Assembly Plant. Pursuing sustainable development is crucial, especially in energy-intensive industries like automotive manufacturing. By promoting scientific and educational interests and fostering actionable projects, AEE aims to drive sustainability measures within the energy industry. WAP's recognition signifies a significant step towards reducing energy consumption and its associated carbon footprint.Overview of the Winning Project:The winning project at Windsor Assembly Plant focused on optimizing the topcoat observation booth downdraft system in the paint shop, aiming to maximize efficiency and minimize energy usage. In total, the project successfully reduced energy consumption by an impressive amount of 20,250 gigajoules (GJ), which translates to an 8% annual reduction in the topcoat process. To comprehend the scale of this achievement, one can consider the electricity used in nearly 490 homes within a single year.Keywords: Topcoat Paint Booth and Its Significance:The keywords 'topcoat paint booth' hold substantial significance within the automotive manufacturing industry. As a crucial stage in the vehicle production process, the topcoat application plays a vital role in ensuring a vehicle's appearance, protection, and durability. Considering the immense energy requirements and potential environmental impact that can accompany this process, optimizing the topcoat paint booth becomes imperative.The project's scope encompassed the entire topcoat observation booth downdraft system, which is responsible for maintaining a controlled environment during the application of the paint. By enhancing efficiency in this area, WAP achieved remarkable energy savings and consequent sustainability benefits.Energy Savings and Environmental Impact:The reduction of energy usage by 20,250 GJ annually in WAP's paint shop represents a significant achievement for sustainability. Beyond the sheer figures, it is crucial to understand the environmental impact of such energy savings. The reduction is equivalent to the electricity consumption of 490 homes in a year. This commendable achievement not only showcases WAP's commitment to energy efficiency but also highlights the enormous potential the automotive industry holds in contributing to a greener future.Implications for Sustainable Manufacturing:The optimization project at Windsor Assembly Plant sets a remarkable precedent for other manufacturing facilities within the industry. By prioritizing energy efficiency and sustainability, WAP not only reduces its carbon footprint but also establishes a roadmap for sustainable manufacturing practices. Collaboration between automakers, energy engineers, and relevant professionals can lead to revolutionary projects that contribute to lasting environmental benefits.Conclusion:In the wake of achieving the 2021 Canada Region Energy Project of the Year award, Stellantis' Windsor Assembly Plant should be commended for its dedication to sustainability and energy efficiency. Through the optimization of the topcoat observation booth downdraft system in their paint shop, the plant has successfully reduced energy consumption by an impressive amount, equivalent to the electricity used in 490 homes in one year. This accomplishment highlights the potential for sustainable development within the automotive industry and sets an example for other manufacturing facilities to follow. With continued collaborative efforts and targeted projects, the industry can pave the way for a greener and more sustainable future.

Affordable Powder Coating Ovens for Curing and Coating

Powder coating is one of the most effective ways of protecting metal surfaces against corrosion, but it requires specialized equipment to get the job done. One of the essential pieces of equipment required in powder coating is a curing oven. There are a variety of curing ovens available in the market, but one that has gained significant attention is the 3x3x6 powder coat oven.The 3x3x6 powder coat oven is a compact and efficient oven that provides heating at consistent temperatures, making it perfect for small workshops and hobbyist applications. It features ample interior space that caters to a variety of workpieces ranging from small to medium-sized items. The oven is equipped with a circulation fan that ensures even heat distribution, which results in uniform curing of the powder coating.The construction of the 3x3x6 powder coat oven comprises high-quality materials that provide durability and longevity of the oven. The interior of the oven is lined with ceramic fiber insulation, which prevents heat loss, reduces energy usage, and ensures rapid heat-up time. The exterior of the oven is built using a heavy-duty steel frame that provides strength and stability to the entire structure.In addition, the 3x3x6 powder coat oven is easy to use and requires minimal maintenance. It features a programmable digital controller that enables the operator to adjust the temperature and curing time, making it possible to achieve the desired outcome for different types of powder coating materials.One of the most significant advantages of the 3x3x6 powder coat oven is its portability. The oven has a compact design that makes it easy to move around and store when not in use. Additionally, the oven is lightweight, making it easy to transport from one location to another.In conclusion, the 3x3x6 powder coat oven is an efficient, compact, and versatile curing oven that is perfect for small workshops and hobbyist applications. It is durable, easy to use, and features a programmable digital controller that allows for precise temperature and curing time adjustments. The oven's portability is an added advantage, making it easy to move around and store. Therefore, if you want to take your powder coating projects to the next level, the 3x3x6 powder coat oven is a worthy investment.

High Performance Spray Booth Extractor for Efficient Workplace Ventilation

Spray Booth Extractor - An Essential Solution for Industrial Air QualityIn today's industrial landscape, ensuring clean and healthy air quality is of utmost importance. With the ever-increasing focus on environmental sustainability and worker safety, companies are constantly seeking innovative solutions to maintain a safe and healthy working environment.One such solution that has been gaining prominence in the industrial sector is the Spray Booth Extractor. This revolutionary piece of equipment plays a crucial role in maintaining clean air within industrial facilities, particularly those involved in painting and coating operations.The Spray Booth Extractor, developed by a leading industrial equipment manufacturer, Company XYZ, is a state-of-the-art system designed to effectively capture and remove paint overspray, fumes, and other airborne contaminants generated during the painting process. By doing so, it helps in improving indoor air quality, reducing hazardous waste, and ensuring compliance with environmental regulations.Company XYZ has been at the forefront of developing innovative solutions for industrial air quality and ventilation for over two decades. With a strong commitment to research and development, the company has continuously invested in cutting-edge technologies to address the evolving needs of its customers.The Spray Booth Extractor is a testament to the company's dedication to delivering high-performance, reliable, and cost-effective solutions for industrial air filtration. Equipped with advanced filtration systems and powerful extraction capabilities, the extractor is capable of effectively capturing and containing airborne particles, ensuring that only clean air is released back into the working environment.Furthermore, the extractor is designed to be energy-efficient, helping companies reduce their carbon footprint and lower operational costs. Its modular design and flexible installation options make it suitable for a wide range of industrial applications, including automotive refinishing, aerospace manufacturing, and general metal fabrication.The effectiveness of the Spray Booth Extractor has been validated through rigorous testing and real-world applications. Numerous companies across various industries have reported significant improvements in air quality and a reduction in respiratory issues among workers after installing the extractor in their facilities.In addition to its functional benefits, the Spray Booth Extractor is also designed with user convenience and safety in mind. It features intuitive controls, easy maintenance access, and built-in safety mechanisms to ensure smooth operation and minimize downtime.Company XYZ's commitment to customer satisfaction extends beyond product development. The company offers comprehensive support services, including installation, training, and ongoing maintenance to ensure that customers derive maximum value from their investment in the Spray Booth Extractor.As industries continue to prioritize environmental sustainability and workplace safety, the demand for solutions like the Spray Booth Extractor is expected to rise. Through its innovative approach and customer-focused philosophy, Company XYZ is well-positioned to meet this growing demand and set new standards for industrial air quality solutions.In conclusion, the Spray Booth Extractor from Company XYZ represents a significant advancement in industrial air filtration technology. With its ability to effectively capture and remove airborne contaminants, improve air quality, and enhance worker safety, it has become an essential solution for companies seeking to maintain a clean and healthy working environment. As the industry continues to evolve, Company XYZ remains dedicated to delivering innovative, reliable, and cost-effective solutions that address the unique challenges of industrial air quality.