High Quality Powder Coating Machine for Efficient and Durable Finishes

By:Admin

The company has a rich history of providing top-of-the-line powder coating machines to a wide range of industries, including automotive, aerospace, furniture, and more. Their machines are known for their durability, precision, and ease of use, making them the go-to choice for businesses looking to improve their powder coating processes.

One of the key features of Powder Coating Machine's equipment is its advanced technology that allows for a more efficient and consistent powder coating application. This not only saves time and money for businesses, but also ensures a higher quality finished product.

In addition, Powder Coating Machine takes pride in its commitment to sustainability. Their equipment is designed to minimize waste and reduce environmental impact, making it a responsible choice for businesses looking to minimize their carbon footprint.

Furthermore, the company offers exceptional customer support and training to ensure that their clients are able to get the most out of their powder coating machines. From installation to ongoing maintenance, Powder Coating Machine is dedicated to providing comprehensive support every step of the way.

Powder Coating Machine's success can also be attributed to their team of experienced and knowledgeable professionals who are passionate about delivering superior powder coating solutions. Their expertise and dedication to customer satisfaction set them apart in the industry and have earned them a strong reputation as a reliable and innovative company.

Recently, Powder Coating Machine has introduced a new line of powder coating machines that are equipped with even more advanced features to further improve the powder coating process. These new machines offer enhanced efficiency, productivity, and flexibility, allowing businesses to take their powder coating capabilities to the next level.

With a focus on continuous improvement and innovation, Powder Coating Machine is poised to continue leading the way in the powder coating equipment market. Their dedication to delivering high-quality, sustainable, and efficient solutions has positioned them as a trusted partner for businesses looking to elevate their powder coating processes.

In conclusion, Powder Coating Machine is a company that is dedicated to providing cutting-edge powder coating solutions to businesses across a variety of industries. Their commitment to innovation, sustainability, and customer satisfaction has established them as a frontrunner in the powder coating equipment market. With a team of experienced professionals and a focus on continuous improvement, Powder Coating Machine is well-positioned to continue driving the industry forward with its advanced and reliable powder coating machines.

Company News & Blog

Guide to Choosing the Best Crop Sprayer Nozzles for Effective Pest Control

Crop Sprayer Nozzles: Enhancing Precision and Efficiency in AgricultureCrop sprayer nozzles are an essential component of modern agricultural machinery, playing a crucial role in ensuring the efficient and precise application of pesticides, fertilizers, and other crop protection products. These nozzles are responsible for delivering the spray solution to the target area, and the design and functionality of the nozzles can have a significant impact on the effectiveness of the application.One company that has been at the forefront of developing innovative and high-quality crop sprayer nozzles is {}. With a strong focus on research and development, coupled with a commitment to meeting the evolving needs of the agricultural industry, {} has established itself as a leading provider of precision agricultural equipment.The company's range of crop sprayer nozzles is designed to address the challenges faced by modern farmers, including the need for precise and uniform application, reduced drift, and overall efficiency. By leveraging cutting-edge technology and a deep understanding of agricultural practices, {} has developed a diverse portfolio of sprayer nozzles that cater to different crops, application requirements, and environmental conditions.One of the key features of {}'s crop sprayer nozzles is their ability to provide consistent droplet size and distribution, ensuring that the spray solution is delivered evenly across the target area. This consistency is critical in maximizing the effectiveness of crop protection products while minimizing waste and environmental impact.Furthermore, {}'s nozzles are designed to reduce drift, which is a major concern in agricultural spraying. Drift occurs when the spray solution is carried away by the wind to unintended areas, potentially causing damage to non-target crops and posing environmental risks. By incorporating features that minimize drift, such as the use of air induction technology and specific spray patterns, {}'s crop sprayer nozzles help farmers to achieve greater precision and minimize the potential for off-target application.In addition to precision and drift reduction, {}'s crop sprayer nozzles are also engineered for durability and ease of maintenance. These qualities are essential for ensuring the reliability and longevity of agricultural equipment, particularly in the demanding conditions of farm operations. By utilizing high-quality materials and robust construction, {}'s nozzles are built to withstand the rigors of agricultural spraying and contribute to the overall efficiency and productivity of farm operations.It is worth noting that {} also offers a range of accessories and support services to complement its crop sprayer nozzles, providing farmers with a comprehensive solution for their spraying needs. From nozzle selection guidance to technical support and aftermarket services, {} is committed to assisting its customers in optimizing their spraying operations and achieving the best possible results.Looking ahead, the demand for advanced and efficient crop sprayer nozzles is expected to continue growing as farmers seek to optimize their use of agricultural inputs and minimize environmental impact. With its ongoing dedication to innovation and customer satisfaction, {} is well-positioned to remain a key player in the field of precision agricultural equipment, including crop sprayer nozzles.In conclusion, crop sprayer nozzles play a crucial role in modern agriculture, and {}'s commitment to developing high-quality, innovative solutions has earned the company a place of distinction in the industry. As farmers strive to achieve greater efficiency, precision, and sustainability in their spraying operations, {}'s crop sprayer nozzles are poised to make a significant contribution to the future of agriculture.

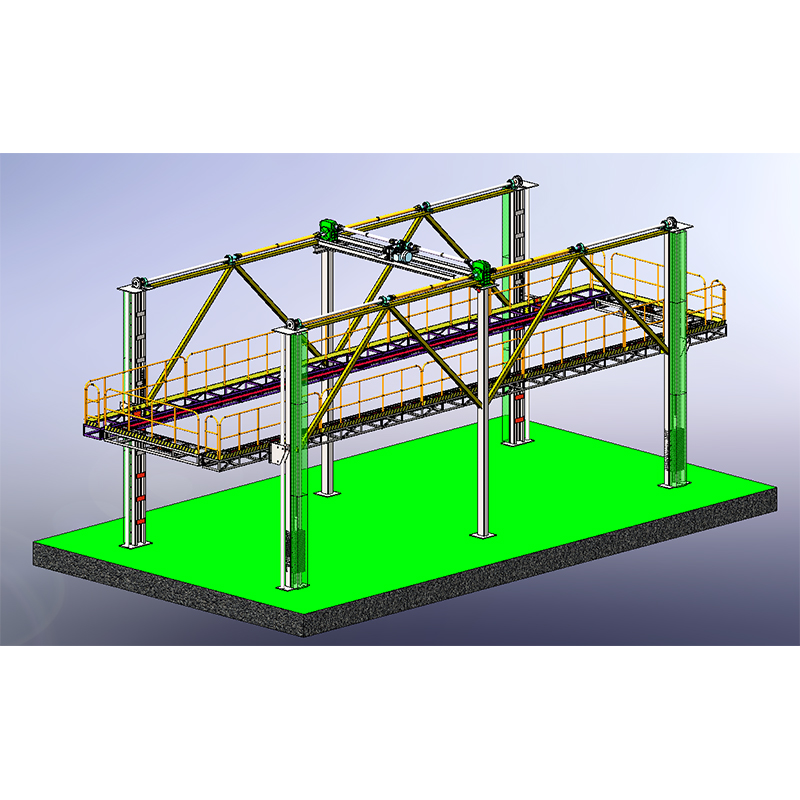

Inverted Power and Free Conveyor System: An Efficient Material Handling Solution

Inverted Power and Free Conveyor Revolutionizes the Manufacturing IndustryThe manufacturing industry is constantly evolving, and new technologies emerge to meet the ever-increasing demands of efficiency, productivity, and cost-effectiveness. One revolutionary system that has gained significant attention in recent times is the Inverted Power and Free Conveyor, spearheaded by an innovative company at the forefront of cutting-edge technology.The Inverted Power and Free Conveyor system has been developed by a forward-thinking company determined to push boundaries and transform the manufacturing landscape. Unlike traditional conveyor systems, this state-of-the-art technology allows for greater flexibility, enhanced control, and increased productivity, making it an ideal choice for a wide range of industries.To fully appreciate the significance of this groundbreaking invention, it is essential to familiarize ourselves with the company behind it. {Company Name}, a renowned leader in industrial automation solutions, has dedicated years of extensive research and development to create the Inverted Power and Free Conveyor system. With a strong commitment to innovation, reliability, and customer satisfaction, {Company Name} has established itself as a trusted partner for businesses seeking to streamline their production processes.The Inverted Power and Free Conveyor system employs a unique design that offers unparalleled efficiency in material handling. By utilizing a combination of an inverted track and an electrically powered chain, the system allows different products to move independently and simultaneously, ensuring continuous and uninterrupted operation. This flexibility enables manufacturers to streamline production, reduce downtime, and maximize throughput.One of the notable features of the Inverted Power and Free Conveyor is its ability to accommodate heavy loads, making it an ideal solution for manufacturing industries that deal with large or bulky items. The system's robust construction guarantees durability and long-lasting performance, minimizing maintenance requirements and reducing overall operational costs.Moreover, this cutting-edge conveyor system comes equipped with advanced control software that provides real-time monitoring, precise tracking, and seamless integration with other production processes. With customizable programming options, manufacturers can optimize the operations of the Inverted Power and Free Conveyor to align with their specific requirements. This level of control enables businesses to achieve optimal efficiency, enhance product quality, and meet the demands of a fast-paced global market.Additionally, the Inverted Power and Free Conveyor system incorporates industry-leading safety features to ensure the well-being of operators and employees. Equipped with sensors and emergency stop mechanisms, the system provides a safe working environment, significantly reducing the risk of accidents or injuries.The benefits of implementing the Inverted Power and Free Conveyor system extend beyond operational efficiency. The environmentally conscious design of the system minimizes energy consumption, promoting sustainability in manufacturing processes. By reducing energy usage, companies can lower their carbon footprint and contribute to a cleaner, greener future.As businesses strive for greater productivity, adaptability, and efficiency, the Inverted Power and Free Conveyor system proves to be a game-changer in the manufacturing industry. With its revolutionary features and unwavering focus on customer satisfaction, {Company Name} has paved the way for a new era of material handling and automation.In conclusion, the Inverted Power and Free Conveyor system developed by {Company Name} represents a significant step forward in industrial automation. Through its innovative design and advanced features, this cutting-edge technology revolutionizes the manufacturing sector, offering businesses improved efficiency, increased productivity, and reduced operating costs. As the global demand for seamless and streamlined production processes continues to grow, the Inverted Power and Free Conveyor system stands at the forefront of innovation, empowering manufacturers to thrive in an increasingly competitive market.

High-Quality Water Wash Spray Booth: A Cost-Effective Solution for Your Painting Needs

Water Wash Spray Booth: The Future of Eco-Friendly Automotive RefinishingIn today's rapidly evolving automotive industry, the demand for eco-friendly and efficient solutions is at an all-time high. As a result, businesses are continuously seeking innovative ways to reduce their environmental impact while simultaneously improving their operational efficiency. One company at the forefront of this movement is [Company Name], a leading provider of cutting-edge automotive refinishing solutions.With a commitment to sustainability and excellence, [Company Name] has recently introduced its revolutionary Water Wash Spray Booth, a state-of-the-art system designed to meet the growing demand for environmentally responsible refinishing processes. This innovative solution has set a new standard for the industry, offering a combination of superior performance, energy efficiency, and reduced environmental impact.The Water Wash Spray Booth is equipped with advanced water wash technology, which allows for the efficient capture and removal of overspray particles from the air. This system does not require the use of chemical solvents or harmful substances, making it a sustainable and eco-friendly alternative to traditional spray booths. By utilizing water as the primary filtration medium, the booth effectively reduces the release of harmful emissions into the atmosphere, resulting in a significantly smaller carbon footprint.Furthermore, the Water Wash Spray Booth is designed to optimize energy utilization, helping businesses reduce their operational costs while minimizing their environmental impact. The booth's innovative design maximizes airflow and ventilation, ensuring that the refinishing process is conducted with maximum efficiency. This not only reduces energy consumption but also allows for faster drying and curing times, enabling businesses to improve their productivity and overall service quality.In addition to its environmental and operational benefits, the Water Wash Spray Booth is also engineered to deliver impeccable refinishing results. The booth's advanced filtration and ventilation system ensure that overspray particles are effectively captured and removed, resulting in a flawless finish for every vehicle. This level of precision and quality is essential for automotive businesses looking to maintain high standards and meet the expectations of their customers.[Company Name] takes pride in its commitment to innovation and sustainability, and the Water Wash Spray Booth exemplifies these core values. This groundbreaking solution is a testament to the company's dedication to driving positive change within the automotive industry, as it continues to lead the way in developing environmentally responsible refinishing technologies.As a responsible global citizen, [Company Name] understands the importance of minimizing its environmental impact and promoting sustainable practices. The Water Wash Spray Booth represents a significant step forward in this ongoing effort, offering businesses a viable and effective solution to reduce their carbon footprint and adopt eco-friendly refinishing processes.By investing in the Water Wash Spray Booth, automotive businesses can not only improve their environmental stewardship but also enhance their operational efficiency and service quality. This innovative system is a game-changer for the industry, empowering businesses to meet the growing demand for eco-friendly and sustainable automotive refinishing solutions while staying competitive in a rapidly evolving market.In conclusion, the Water Wash Spray Booth from [Company Name] stands as a testament to the company's unwavering commitment to innovation, sustainability, and excellence. This revolutionary solution has raised the bar for eco-friendly automotive refinishing, offering businesses a way to reduce their environmental impact, improve their operational efficiency, and deliver exceptional results. As the industry continues to evolve, [Company Name] remains dedicated to driving positive change and empowering businesses to thrive in a sustainable and responsible manner.

Maximizing Efficiency and Quality with Electrostatic Powder Coating

Electrostatic Powder Coating Technology Revolutionizing the Coating IndustryIn the modern manufacturing industry, the demand for durable and high-quality coatings is ever-pressing. To meet this need, companies are constantly seeking innovative and efficient coating solutions. One such solution that has been making waves in the industry is electrostatic powder coating technology. This revolutionary form of coating has been widely adopted by various industries due to its numerous advantages, and one company that has been leading the way in this technology is {Company Name}.{Company Name} is a renowned industry leader in the field of electrostatic powder coating, offering a wide range of cutting-edge coating solutions for a diverse range of applications. With a strong focus on innovation and quality, the company has quickly gained a reputation for being a preferred choice for businesses seeking top-notch coating solutions.Electrostatic powder coating is a process that involves applying a dry powder to a surface and then curing it with heat to form a hard finish. The key to this technology lies in its electrostatic application method, where the powder particles are charged with an electric current and then applied to the surface using an electrostatic gun. This unique process allows the powder to adhere to the surface in a uniform and efficient manner, resulting in a smooth and durable finish.One of the major advantages of electrostatic powder coating is its environmentally friendly nature. Unlike traditional liquid coatings, powder coatings do not contain harmful solvents, making them a much safer and greener option. Additionally, the process produces minimal waste, as any overspray can be collected and reused, further reducing the environmental impact.Furthermore, electrostatic powder coating offers superior durability and resistance to corrosion, chemicals, and weathering. This makes it an ideal choice for applications that require long-lasting and high-performance coatings, such as automotive parts, furniture, appliances, and industrial machinery.{Company Name} has been at the forefront of advancing this technology, continually innovating to develop new and improved coatings that meet the evolving needs of its customers. The company's team of experts is dedicated to pushing the boundaries of what is possible with electrostatic powder coating, constantly exploring new techniques and materials to enhance the performance and versatility of their products.In addition to its commitment to innovation, {Company Name} also places a strong emphasis on quality and customer satisfaction. Each coating solution undergoes rigorous testing to ensure it meets the highest standards of performance and reliability. Moreover, the company's team works closely with clients to understand their specific requirements and provide tailored solutions to meet their unique coating needs.The success of {Company Name} can be attributed to its dedication to excellence and its ability to consistently deliver exceptional products and services. With a strong track record of customer satisfaction and a growing list of successful projects, the company has established itself as a trusted partner for businesses looking to achieve superior coating solutions.Looking ahead, the future of electrostatic powder coating looks promising, with {Company Name} poised to continue driving innovation and setting new benchmarks for the industry. As the demand for high-performance and sustainable coatings continues to grow, it is clear that electrostatic powder coating will play a crucial role in shaping the future of the coating industry.In conclusion, electrostatic powder coating technology has proven to be a game-changer in the coating industry, offering a range of benefits including environmental sustainability, durability, and high performance. {Company Name} has been instrumental in advancing this technology, providing top-quality coating solutions and setting new standards for excellence. As the industry evolves, {Company Name} remains committed to leading the way and delivering innovative solutions that meet the needs of its customers.

Automated Paint Booth Robots: Increasing Efficiency and Productivity

Automated Paint Booth Robots Revolutionize Manufacturing Process at {}The manufacturing industry has witnessed a substantial transformation in recent years, thanks to the advent of automation and robotics. One key area where this transformation has been particularly prominent is in the paint booth, where the integration of robotic technology has revolutionized the painting process. One company at the forefront of this revolution is {}, a leading provider of state-of-the-art robotics solutions for manufacturing industries.With over 20 years of experience in the field, {} has established itself as a pioneer in the development and integration of paint booth robots. These advanced robots are designed to streamline the painting process, improve efficiency, and ensure consistent quality in the finished product. By leveraging cutting-edge technology and expertise, {} has helped numerous manufacturing plants around the world achieve significant cost savings and productivity improvements.The primary goal of paint booth robots developed by {} is to eliminate the traditional challenges associated with manual painting processes. These challenges include prolonged painting times, uneven coating application, and high material waste. By implementing robot-assisted painting solutions, manufacturers can overcome these hurdles and achieve a level of precision and efficiency that was previously unattainable.The key features of {} paint booth robots include:1. Advanced Programming: {} robots are equipped with sophisticated programming capabilities that allow for precise control over the painting process. This ensures consistent and uniform coating application on various surfaces, regardless of the complexity of the parts being painted.2. Integration with Paint Systems: {} robots are designed to seamlessly integrate with different types of paint systems, including airless, electrostatic, and powder coating. This flexibility enables manufacturers to optimize their painting processes according to their specific requirements.3. Improved Efficiency: By automating the painting process, {} robots can significantly reduce painting cycle times, leading to increased productivity and reduced lead times. This improved efficiency translates to cost savings and enhanced competitiveness for manufacturing plants.4. Quality Control: {} robots are equipped with advanced sensors and vision systems that enable real-time monitoring of the painting process. This allows for immediate detection and correction of any defects or inconsistencies in the coating, ensuring high-quality finished products.5. Operator Safety: By taking over the painting process, {} robots minimize the exposure of human operators to potentially hazardous painting chemicals, thus ensuring a safer working environment.One of the key advantages of {} paint booth robots is their ability to adapt to a wide range of manufacturing environments. Whether it's automotive, aerospace, furniture, or general metal fabrication, {} robots can be customized to meet the specific painting needs of different industries. This versatility has made {} a preferred partner for manufacturers seeking to optimize their painting processes.In addition to the technological capabilities of its paint booth robots, {} also offers comprehensive support and maintenance services to ensure the smooth operation of its robotic systems. This includes training programs for plant personnel, preventative maintenance schedules, and 24/7 technical support to address any issues that may arise.The impact of {} paint booth robots on the manufacturing industry has been nothing short of transformative. By automating the painting process, {} has helped its clients achieve significant improvements in productivity, cost savings, and product quality. As the demand for efficient and sustainable manufacturing processes continues to grow, the role of paint booth robots will undoubtedly become increasingly vital in driving the future of manufacturing.In conclusion, the integration of paint booth robots developed by {} has ushered in a new era of efficiency and precision in the manufacturing industry. With its advanced technology, comprehensive support services, and proven track record, {} is poised to continue leading the way in revolutionizing the painting process for manufacturers worldwide.

The Ultimate Guide to Powder Coating: Everything You Need to Know

Manual Powder Coating: The Latest Innovation from {Company}{Company} is proud to announce the latest addition to its line of innovative products – Manual Powder Coating. With the introduction of this new technology, {Company} continues to solidify its position as a leader in the powder coating industry.Manual Powder Coating is a versatile and efficient solution for applying a durable and uniform finish to a wide range of surfaces. It offers several advantages over traditional liquid painting, including better durability, improved appearance, and enhanced resistance to chipping, scratching, and fading. This makes it an ideal choice for a variety of applications, including automotive parts, metal furniture, machinery, and much more.{Company} has developed a comprehensive range of Manual Powder Coating equipment and supplies, designed to meet the specific needs of its customers. This includes a selection of powder coating guns, control units, and accessories, as well as a variety of powders in different colors and finishes. Additionally, {Company} offers expert technical support and training to ensure that customers can achieve the best results with their Manual Powder Coating systems.One of the key advantages of Manual Powder Coating is its environmental friendliness. Unlike liquid paint, powder coating does not contain harmful solvents or volatile organic compounds (VOCs), making it a more sustainable and eco-friendly option. This has become increasingly important as businesses and consumers alike seek out greener and more responsible alternatives to traditional coating methods.With the introduction of Manual Powder Coating, {Company} has once again demonstrated its commitment to innovation and excellence in the field of surface finishing. The company has a long-standing reputation for delivering high-quality products and exceptional customer service, and this latest offering is no exception.In addition to its Manual Powder Coating systems, {Company} offers a wide range of other products and services to support its customers' coating needs. This includes automated powder coating systems, liquid painting equipment, surface preparation solutions, and more. {Company} prides itself on being a one-stop shop for all surface finishing requirements, providing everything from equipment and supplies to technical expertise and support.{Company} has established itself as a trusted partner for businesses across a diverse range of industries, from automotive and aerospace to furniture and architecture. With its broad expertise and dedication to customer satisfaction, {Company} has earned a strong and loyal customer base, both domestically and internationally.As the demand for high-quality and sustainable surface finishing solutions continues to grow, {Company} is well-positioned to meet the needs of its customers with its Manual Powder Coating technology. The company remains committed to pushing the boundaries of innovation and delivering cutting-edge solutions that deliver superior results.For more information about Manual Powder Coating and other products and services offered by {Company}, please visit their website or contact their customer service team.

New Protective Painting Technology Revolutionizes Manufacturing Processes

Protective Painting Line: Protecting Your Products from Corrosion and WearIn today's fast-paced world, where consumerism has taken the forefront, product quality has become a key factor in determining customer satisfaction. Whether it is electronic gadgets, automobiles, kitchen appliances or any other products, they all need to be protected from the harsh environment and extreme usage conditions. This is where the Protective Painting Line comes into play.The Protective Painting Line is a sophisticated technology that is capable of providing quality corrosion and wear protection to a wide range of products. By applying a layer of protective paint coating, this advanced system has the potential to protect your products from the harmful effects of rust, corrosion and wear.Benefits of Protective Painting Line:One of the main advantages of the Protective Painting Line technology is that it can help in extending the overall life of products, thereby increasing their durability. This is especially true for products that are used in harsh environments or are subjected to extreme usage conditions. Protective paint coatings can significantly reduce the impact of wear and tear and prevent corrosion and rusting, thus reducing the frequency of repairs and replacements.Additionally, this technology can also help in improving the aesthetic appeal of products by providing a smooth and attractive finish. By masking existing blemishes, scratches, and other imperfections, a protective paint coating can enhance the overall presentation of products, making them more visually appealing to potential customers.The Protective Painting Line is also eco-friendly and cost-effective. Unlike other conventional methods, a protective coating system can be applied to complex-shaped products with ease. This helps in reducing the overall manufacturing costs and minimizes the amount of material waste generated during production.{Company Introduction}Combining the Protective Painting Line technology with our company's expertise, we are helping industries worldwide to produce better quality products that last longer and maintain their attractive appearance. Our company has been providing protective paint coatings for over a decade and has served a diverse clientele across the globe. With our state-of-the-art equipment and experienced professionals, we can apply protective coatings to products of any size and shape, regardless of their complexity.We specialize in providing custom coatings for various industries, including marine, automotive, electronics, machinery and equipment, and architectural applications. Our coatings are designed to meet the specific requirements of each product and offer superior protection against corrosion, wear, and abrasion.Our manufacturing processes comply with major industry standards and regulations, and we work closely with our clients to ensure that the products we deliver meet their expectations. We also provide comprehensive after-sales support, including routine maintenance and repairs, to ensure that our coatings perform at their optimal level throughout their lifespan.In conclusion, the Protective Painting Line technology is an essential tool for protecting products from corrosion and wear. By extending the lifespan of products, improving their aesthetics and being eco-friendly, this technology is revolutionizing the way industries are producing and delivering products. At our company, we are committed to providing quality protective coatings that offer the best value to our clients. So, join us, and let's protect your products and enhance their longevity together.

High-Quality Spray Gun for Professional Painting Jobs

Prona Spray Gun revolutionizing the painting industry with its innovative technologyThe painting industry has seen tremendous advancements in technology over the years, and one company that has been at the forefront of these innovations is Prona. With its state-of-the-art spray gun technology, Prona has been revolutionizing the way professionals in the painting industry work.Founded in 1996, Prona has been dedicated to designing and manufacturing high-quality spray guns that are not only efficient and reliable but also environmentally friendly. With a focus on innovation and customer satisfaction, Prona has become a trusted name in the industry, with a global presence and a loyal customer base.One of the most revolutionary products from Prona is its advanced spray gun, which has been designed to deliver superior results while minimizing waste and environmental impact. This innovative spray gun is equipped with the latest technology, including precision engineering and advanced materials, to ensure a consistent and flawless finish every time.The Prona spray gun is also designed with ergonomics in mind, with a lightweight and balanced design that reduces fatigue and improves productivity. It also features a user-friendly interface, making it easy for professionals to customize and control the spray pattern and paint flow to suit the specific requirements of each project.In addition to its cutting-edge technology, the Prona spray gun is also designed to be environmentally friendly. It is equipped with advanced air cap technology that reduces overspray and ensures that more paint reaches the surface, minimizing waste and maximizing efficiency. This not only saves money for professionals but also reduces the environmental impact of painting projects.Furthermore, Prona is committed to sustainability and has integrated eco-friendly materials and production processes into the manufacturing of its spray guns. The company also offers comprehensive training and support to help professionals maximize the performance of their spray guns while minimizing their environmental footprint.With its innovative technology and commitment to excellence, Prona has been gaining recognition and accolades in the industry. Professionals who have used the Prona spray gun have praised its performance, reliability, and durability, making it a preferred choice for a wide range of painting applications.In addition to its advanced spray guns, Prona also offers a comprehensive range of accessories and spare parts to ensure that professionals can get the most out of their equipment. The company’s dedication to customer satisfaction is evident in its commitment to providing high-quality products and exceptional after-sales support.As Prona continues to push the boundaries of innovation in the painting industry, it is poised to remain a leader in the market for years to come. With its focus on technology, sustainability, and customer satisfaction, Prona is setting new standards for excellence in the professional painting industry.In conclusion, Prona has been making waves in the painting industry with its advanced spray gun technology. With its commitment to innovation, sustainability, and customer satisfaction, Prona is revolutionizing the way professionals work and setting new standards for excellence in the industry. Professionals who are looking for high-quality, reliable, and environmentally friendly spray guns need look no further than Prona.

Quality Spray Nozzles, Caps, Strainers, Nozzle Bodies & Clamps for Sprayers and Landscaping Equipment

article on the importance of quality spray nozzles in gardening, landscaping, and agriculture.Spray nozzles may seem like small and insignificant components of gardening, landscaping, and agricultural equipment, but they play a crucial role in ensuring the effectiveness and efficiency of various spraying applications. Whether you are irrigating your lawn, spraying fertilizers or herbicides in your crops, or beautifying your garden with pesticides, having high-quality spray nozzles can make a difference in achieving your desired outcomes.There are different types of spray nozzles available in the market, each designed to deliver specific spraying patterns, flow rates, and droplet sizes. Choosing the right spray nozzle for your application is critical in achieving optimal coverage and minimizing wastage of resources such as water, chemicals, and time. It is also important to consider factors such as the pressure and velocity of the liquid being sprayed, the type of surface being treated, and the environmental conditions in which the spraying is being done.One of the leading causes of spray nozzle failure is clogging, which can result from debris, sediment, or minerals in the liquid, or from the accumulation of deposits over time. Clogged spray nozzles can cause uneven spraying, reduced coverage, and increased maintenance costs. To prevent clogging, it is imperative to use high-quality strainers and filters that can trap particles as small as 5 microns and remove sediment and other impurities that can damage the nozzle. Regular cleaning and maintenance of spray nozzles are also essential in prolonging their lifespan and ensuring their performance.Another crucial factor in choosing spray nozzles is their material of construction. Low-quality nozzles made of inferior materials such as plastic or cheap alloys may wear out quickly, corrode easily, and result in frequent replacement. High-quality nozzles, on the other hand, are made of durable and corrosion-resistant materials such as stainless steel, brass, or ceramic, that can withstand harsh conditions, resist chemical attack, and maintain their shape and precision over time. Investing in high-quality nozzles not only prevents downtime and replacement costs but also improves the consistency and accuracy of your spraying applications.When it comes to choosing a supplier for your spray nozzles and related equipment, it is important to look for a reputable and experienced company that offers a wide range of products and services. A good supplier should be able to provide expert advice and support, fast and reliable delivery, competitive pricing, and customized solutions to meet your specific needs. They should also offer a comprehensive warranty and after-sales service to ensure that you get the most out of your investment and achieve maximum productivity and efficiency.In conclusion, spray nozzles may be small and simple components, but they are critical to the success of many spraying applications in gardening, landscaping, and agriculture. Choosing high-quality nozzles, strainers, and related equipment and partnering with a reputable and reliable supplier can help you achieve optimal coverage, minimize wastage and downtime, and increase productivity and profitability in your spraying operations.