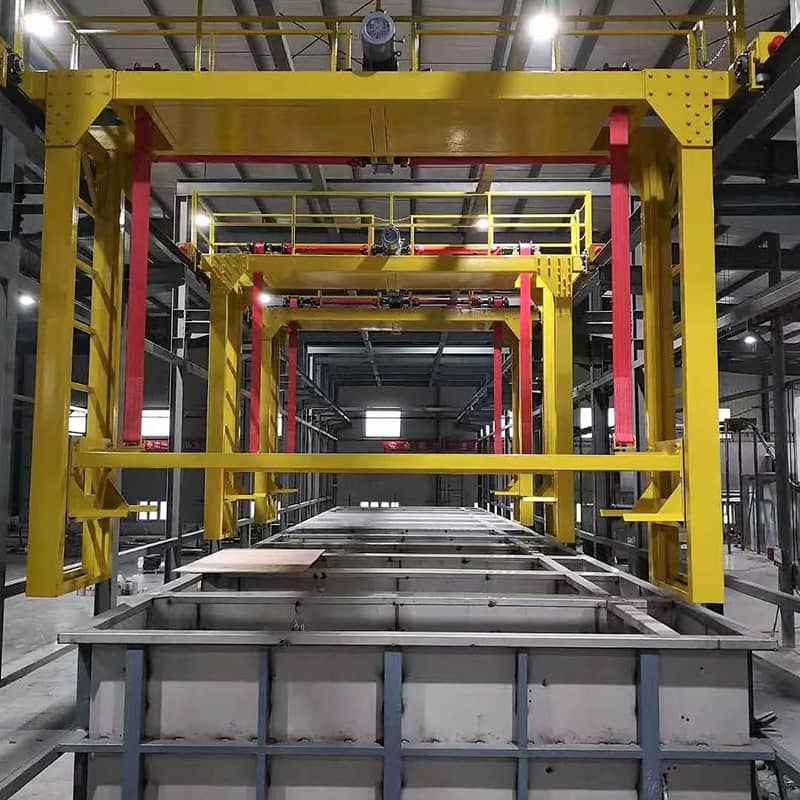

Advanced Skid Conveyance System Optimizes Material Handling

By:Admin

In today's fast-paced manufacturing industry, efficiency and productivity are key factors for success. With the constant need to streamline processes and improve output, companies are always on the lookout for innovative solutions to enhance their operations. This is where the Skid Conveyance System comes into play, offering a groundbreaking solution that is set to revolutionize the way materials are transported and managed within manufacturing facilities.

The Skid Conveyance System, developed by a leading industrial technology company, is a state-of-the-art solution designed to meet the demands of modern manufacturing environments. It is capable of moving heavy loads with ease, making it an ideal choice for industries where large and bulky materials need to be transported efficiently. The system's advanced design and robust construction make it durable and reliable, ensuring smooth and uninterrupted operation even in the most demanding production settings.

One of the most impressive features of the Skid Conveyance System is its versatility. It is easily customizable to fit the specific needs and requirements of different manufacturing processes. Whether it's transporting raw materials, work-in-progress components, or finished products, this system can be tailored to handle a wide range of materials, making it a truly versatile and adaptable solution for various industrial applications.

Furthermore, the Skid Conveyance System is designed with efficiency in mind. Its automated operation and high-speed capabilities help to significantly reduce material handling times, ultimately leading to improved throughput and productivity. This is especially crucial in today's competitive manufacturing landscape, where every second counts and optimizing production processes can make a significant impact on the bottom line.

The system's advanced control technology allows for seamless integration with existing manufacturing systems, enabling companies to enhance their overall production efficiency with minimal disruption to their current operations. This means that implementing the Skid Conveyance System does not entail a complete overhaul of existing processes, but rather a seamless integration that brings immediate benefits to the production floor.

Moreover, the Skid Conveyance System is designed with safety as a top priority. With various built-in safety features and fail-safe mechanisms, the system ensures that materials are transported securely and workers are protected from potential hazards. This focus on safety not only complies with industry regulations and standards but also provides peace of mind for companies looking to create a safe and secure working environment for their employees.

In addition to its impressive capabilities, the Skid Conveyance System is backed by a dedicated team of experts who provide comprehensive support and maintenance services. This ensures that the system operates at peak performance at all times, minimizing downtime and maximizing its lifespan. Furthermore, the company offers ongoing training and technical assistance to ensure that clients are fully proficient in utilizing the system to its fullest potential.

Overall, the Skid Conveyance System offers a game-changing solution that has the potential to transform manufacturing processes across a wide range of industries. With its advanced technology, customizable design, and focus on efficiency and safety, this system represents a significant leap forward in material handling and transportation within the manufacturing sector. As companies continue to seek ways to optimize their operations and remain competitive in the global market, the Skid Conveyance System is poised to become an essential tool for those looking to stay ahead of the curve in the ever-evolving manufacturing landscape.

Company News & Blog

Revolutionary New Powder Coating Oven for Large-scale Projects

In a move to improve its production capacity and efficiency, a leading powder coating company has invested in a brand-new industrial oven that promises to revolutionize its coating processes. Manufactured by a reputable engineering firm, the large-scale oven is capable of producing high-quality coatings on large volumes of parts and products.The new oven features state-of-the-art technology that ensures precise temperature control and uniform heat distribution throughout the chamber. This is crucial in powder coating, as even the slightest temperature variations can have a significant impact on the final product's appearance and durability. With the carefully designed air-flow system and advanced heating elements, the oven provides consistent and reliable curing for a wide range of coating materials, including epoxies, polyesters, hybrids, and fluoropolymers.The oven's size is another impressive factor, as it can accommodate large parts and products up to 16 feet in length, 8 feet in height, and 8 feet in width. This translates to a massive increase in throughput for the company, as it can now handle bigger projects and batch sizes that were previously unfeasible. This feature is essential for companies that require quick turnaround times and high-volume production, such as manufacturers of automotive parts, industrial machinery, and consumer goods.The investment in the new oven is part of the company's strategic plan to stay ahead of the competition and meet the growing demands of its customers. With an expanding client base that demands high-quality finishes and fast turnaround, the company needed to upgrade its facilities to maintain its position as a leader in the powder coating industry.The company is committed to sustainable practices and reducing its carbon footprint, and the new oven contributes significantly to this goal. Its energy-efficient design and high-performance insulation allow it to use less fuel and reduce emissions, resulting in lower operating costs and environmental impact.David Smith, the company's CEO, expressed his excitement about the new addition to their production line. He said, "We're thrilled to have this new oven installed and fully operational. It's a game-changer for us, as it allows us to take on bigger projects, improve our quality control, and increase our throughput. We're committed to investing in the latest technology and providing the highest level of service to our customers."The company has been in operation for over a decade and has built a reputation for quality and reliability in the powder coating industry. Its clients include small businesses, multinational corporations, and government agencies, spanning diverse industries such as aerospace, construction, and medical equipment.In conclusion, the installation of the new industrial oven marks a significant milestone for the powder coating company, enabling it to provide better services to its clients, improve its production efficiency, and contribute to its sustainability goals. With its cutting-edge technology, large capacity, and energy-efficient design, the oven is set to become a vital tool in the company's operations and a valuable asset for its clients.

Revolutionary advancements in Paint Line technology reshaping the industry

The Prime Paint Line company is revolutionizing the paint industry with its innovative and sustainable approach to paint production. The company has recently announced its latest paint line, which promises to provide durable and long-lasting paint solutions for commercial and residential use.The new paint line, which includes a range of high-quality and environmentally friendly paint products, is the result of extensive research and development efforts by the Prime Paint Line team. The company is committed to using state-of-the-art technology and sustainable practices to create paints that not only meet the highest standards of quality and performance but also have minimal impact on the environment.In addition to its commitment to sustainability, Prime Paint Line also places a strong emphasis on customer satisfaction. The company prides itself on providing superior customer service and support, ensuring that clients receive the best products and assistance when it comes to choosing the right paint for their specific needs.Prime Paint Line's new paint line is set to be a game-changer in the industry, offering a wide range of colors and finishes that cater to the diverse needs of its customers. Whether it's for interior or exterior use, the new paint line promises to deliver exceptional performance and aesthetic appeal.One of the key features of the new paint line is its exceptional durability. The paints are designed to withstand the test of time, providing long-lasting protection and beauty for both commercial and residential properties. This makes Prime Paint Line an ideal choice for homeowners, contractors, and businesses looking for reliable and high-quality paint solutions.Furthermore, Prime Paint Line's commitment to sustainability means that the new paint line is formulated with low VOC (volatile organic compound) content, reducing harmful emissions and promoting better indoor air quality. This makes it not only a safe choice for the environment but also for the health and well-being of those who use the paints.Prime Paint Line's dedication to innovation and excellence has positioned it as a leader in the paint industry. The company's state-of-the-art facilities and cutting-edge technology enable it to produce paints that are unmatched in quality and performance. From the selection of raw materials to the production and testing of the final products, Prime Paint Line adheres to the highest standards to ensure that its paints meet and exceed customer expectations.The company's commitment to sustainability extends beyond its products to its manufacturing processes and business operations. Prime Paint Line works tirelessly to minimize its environmental footprint, whether it's through energy-efficient practices, waste reduction, or recycling initiatives. This demonstrates the company's holistic approach to sustainability and its dedication to being a responsible corporate citizen.In conclusion, Prime Paint Line's new paint line is set to make a significant impact in the paint industry. With its focus on sustainability, quality, and customer satisfaction, the company is poised to transform the way people view and use paint. Whether it's for a residential renovation or a large commercial project, Prime Paint Line's new paint line offers a reliable and environmentally friendly solution for all painting needs.

High-Quality Small Powder Curing Ovens from Chinese Manufacturers and Suppliers

A small powdercoating oven is an essential piece of equipment for businesses and DIY enthusiasts who want to achieve long-lasting, high-quality finishes on their metal and plastic projects. These ovens are designed to cure powder coatings by baking them onto the surface of the substrate, creating a durable and attractive finish that resists wear, corrosion, fading, and chipping.At Hangzhou Color Powder Coating Equipment, we offer a range of small powdercoating ovens that are perfect for small-scale projects, such as automotive parts, motorcycle frames, bicycle components, jewelry, and DIY home improvement projects. Our ovens are made with high-quality materials and components, ensuring reliable performance, fast heat up times, and even temperature distribution throughout the curing process.One of the key advantages of using a small powdercoating oven is the ability to achieve a professional-grade finish without the need for expensive spray booths or specialized equipment. With a small oven, you can easily apply powder coatings using a spray gun or electrostatic method, and then cure them in the oven for a few minutes to achieve a hard, durable finish.Another advantage of a small powdercoating oven is its energy efficiency. These ovens are designed to minimize heat loss and maximize heat retention, which means that they consume less energy and require less time to heat up and cool down. This translates into significant cost savings over the long term, especially for DIY enthusiasts who use the oven frequently.When choosing a small powdercoating oven, it's important to consider a few key factors, such as the size of the oven, the type of heating element, the temperature range, and the ease of use. At Hangzhou Color Powder Coating Equipment, we offer a variety of small powdercoating ovens to suit different needs and budgets, from basic models with manual controls to advanced models with programmable digital interfaces.Overall, a small powdercoating oven is an excellent investment for anyone who wants to achieve professional-grade finishes on their metal and plastic projects. With its energy efficiency, durability, and ease of use, this equipment can help you take your DIY hobby or small business to the next level.

Inexpensive Powder Coating Oven Made from Old File Cabinet

DIY Powder Coat Oven Door Seal: A Vital Component in Your Powder Coating SetupPowder coating has quickly become a popular method of applying a durable and uniform finish to metal parts. While it is a relatively simple process, there are specific requirements that must be met to achieve the desired results. One crucial component of any successful powder coating setup is a high-quality oven to cure the powder-coated parts.Commercial powder coat ovens can be expensive, with prices ranging from a few thousand dollars up to tens of thousands of dollars. Fortunately, with a bit of ingenuity and a few basic tools, you can build your own DIY powder coating oven at a fraction of the cost.The key to building a successful oven is to source a suitable enclosure that can withstand high temperatures and provide good insulation. For many DIYers, an old file cabinet or discarded refrigerator can work well. The next step is to add insulation materials like fiberglass or ceramic fiber blankets to improve the oven’s heat retention capabilities.Once you have designed and built the perfect oven enclosure, it’s time to focus on the smaller components that will make or break your powder coating results. One such essential element is the oven door seal. In this blog, we will discuss the importance of a good oven door seal and guide you through the process of making one for your DIY powder coating oven.Why You Need an Oven Door SealThe main purpose of a door seal is to keep the heat trapped inside the oven. You need the heat to cure the powder-coated parts properly. An ill-fitting or worn door seal can allow heat to escape, leading to uneven curing and poorly coated parts.Additionally, having a good seal creates a controlled environment inside the oven, preventing outside contaminants such as dust and debris from entering the oven and adhering to the newly coated parts.How to Make Your Own Oven Door SealTo make your own DIY oven door seal, you will need a few basic tools and materials:- High-temperature silicone- A caulking gun- Masking tape- A sharp utility knifeHere are the steps to follow:Step 1: Measure the Dimensions of Your Oven DoorUse a tape measure to accurately determine the dimensions of your oven door. You will need this information to calculate the length of silicone sealant you need for the job.Step 2: Apply Masking Tape to the Oven Door FrameProtect the areas around the oven door by applying masking tape to the edges of the oven frame. This will prevent the silicone from sticking to areas where it is not needed.Step 3: Apply the Silicone SealantLoad the high-temperature silicone into the caulking gun and apply a thin bead of silicone around the perimeter of the oven door frame, ensuring that it forms a continuous seal. Pay extra attention to the corners and areas where the door typically leaks heat.Step 4: Smooth the Silicone SealantUse your finger or a plastic spatula to smooth out the silicone sealant, ensuring that it fills any gaps or inconsistencies in the oven door. Take your time and be thorough in this step as it can significantly impact the effectiveness of the finished door seal.Step 5: Allow the Silicone to CureFollow the manufacturer's instructions for curing the silicone sealant. Typically, a high-temperature silicone sealant will require at least 24 hours of curing time.Step 6: Test Your New Oven Door SealAfter the silicone sealant has cured, remove the masking tape and close the oven door. Test the seal by running your hand around the door frame and feeling for any escaping heat.A DIY oven door seal made of high-temperature silicone is a cost-effective solution to ensure optimal heat retention and a controlled environment inside your powder coating oven. With a little bit of effort and some handy tools, you can create an effective oven door seal that will help you achieve the best possible results from your powder coating process. In summary, when building a DIY powder coating oven, the oven door seal is a vital component that cannot be overlooked. By following our guide and using high-temperature silicone, you can create a sturdy and reliable oven door seal that will last for years to come.

Efficient Semi Down Draft Spray Booth for Your Painting Needs

Semi Down Draft Spray Booth: The Perfect Solution for Automotive RefinishingIn today’s fast-paced world, the automotive industry is constantly evolving to meet the demands of consumers. With this in mind, {Company Name} is proud to introduce its innovative Semi Down Draft Spray Booth, designed to provide a high-quality and efficient solution for automotive refinishing.{Company Name} has been a leading provider of automotive equipment and solutions for over twenty years. With a commitment to excellence and innovation, the company has established itself as a trusted name in the industry. The introduction of the Semi Down Draft Spray Booth is a testament to the company’s dedication to providing top-of-the-line products that meet the evolving needs of their customers.The Semi Down Draft Spray Booth is a state-of-the-art paint booth that is specifically designed to provide optimal performance and efficiency for automotive refinishing. Equipped with advanced technology and high-quality materials, this spray booth offers a range of features that set it apart from traditional models.One of the key features of the Semi Down Draft Spray Booth is its innovative airflow system, which is designed to provide a consistent and even distribution of air throughout the booth. This ensures that the paint application process is smooth and uniform, resulting in a flawless finish for automotive vehicles. Additionally, the booth is equipped with high-efficiency filtration systems that effectively capture overspray and contaminants, creating a clean and safe work environment for technicians.Another notable feature of the Semi Down Draft Spray Booth is its user-friendly design. With a focus on convenience and ease of use, the booth is equipped with intuitive controls and ergonomic features that allow technicians to work efficiently and comfortably. This not only enhances the overall productivity of the refinishing process but also provides a more enjoyable working experience for employees.In addition to its advanced features, the Semi Down Draft Spray Booth is also praised for its energy efficiency and environmental considerations. The booth is designed to minimize energy consumption, reducing operational costs for businesses while also minimizing its impact on the environment. This aligns with {Company Name}’s commitment to sustainability and responsible business practices.The Semi Down Draft Spray Booth is also designed to meet the highest safety standards, providing a secure and controlled environment for automotive refinishing. Equipped with advanced ventilation systems and safety features, the booth ensures that technicians are protected from harmful fumes and chemicals, allowing them to work with confidence and peace of mind.As the automotive industry continues to evolve, the demand for high-quality refinishing solutions has never been greater. With its innovative features, user-friendly design, and commitment to safety and sustainability, the Semi Down Draft Spray Booth from {Company Name} is poised to meet the needs of businesses and technicians in the automotive sector.In conclusion, the introduction of the Semi Down Draft Spray Booth represents a significant milestone for {Company Name}. With its innovative features, advanced technology, and commitment to excellence, this product is set to make a lasting impact in the automotive industry, providing a high-quality and efficient solution for automotive refinishing. As the company continues to push the boundaries of innovation and quality, the Semi Down Draft Spray Booth stands as a testament to {Company Name}’s dedication to providing the best products and solutions for their customers.

Buy Paint Spray Booths and Powder Spray Booths Online and Save up to 17%!

Paint Spray Booths | Powder Spray Booths: Offering High-Quality Solutions to the Automotive Industry[City], [Date] - In today's competitive market, the automotive industry faces various challenges, one of which is ensuring the highest quality finishes on vehicles. To meet this demand, [Company Name] introduces its extensive range of paint and powder spray booths, providing top-of-the-line solutions to automotive manufacturers and repair shops. The company's commitment to delivering high-quality products has made it a leader in the industry.[Company Name] takes pride in its state-of-the-art paint and powder spray booths, designed to meet the specific needs of customers. These booths offer a controlled environment for optimal painting and finishing results, ensuring a flawless end product. With their advanced ventilation systems and safety features, [Company Name]'s spray booths provide a safe and efficient working environment, prioritizing the well-being of workers.One of the main advantages of [Company Name]'s spray booths is their versatility. The company offers a wide range of booth sizes and configurations, allowing customers to choose the option that best suits their requirements. Whether it's a small repair shop or a large-scale manufacturing facility, [Company Name] has the perfect solution to accommodate any project size.Moreover, [Company Name]'s spray booths are equipped with cutting-edge technology, enabling precise control over temperature, humidity, and airflow. This level of control ensures consistent and high-quality finishes, meeting the demanding standards of the automotive industry. Additionally, their booths are designed to minimize overspray and eliminate dust particles, further enhancing the quality of the final product.Ensuring customer satisfaction is a top priority for [Company Name]. The company's team of experts works closely with each client to understand their specific needs and provide tailored solutions to meet them. By maintaining open lines of communication and accommodating unique requirements, [Company Name] has built a strong reputation for exceptional customer service.Furthermore, [Company Name] strives to exceed industry standards by continuously investing in research and development. The company keeps up with the latest advancements in spray booth technology, enabling them to offer cutting-edge products that optimize productivity, efficiency, and environmental sustainability. By providing environmentally friendly options, [Company Name] supports its clients in their efforts to reduce their carbon footprint and contribute to a greener future.As the automotive industry evolves, [Company Name] remains committed to innovation and improvement. With a focus on customer satisfaction and a dedication to delivering the highest quality solutions, the company continues to set new industry standards. By harnessing the power of advanced technology and expertise, [Company Name] empowers its customers to achieve outstanding results, solidifying its position as an industry leader.In conclusion, [Company Name] offers a comprehensive range of paint and powder spray booths that cater to the needs of the automotive industry. With their commitment to quality, exceptional customer service, and dedication to innovation, [Company Name] has firmly established itself as a trusted provider in the industry. By investing in their state-of-the-art spray booths, automotive manufacturers and repair shops can achieve superior finishes, streamline their operations, and stay ahead of the competition.For more information about [Company Name] and their paint and powder spray booths, please visit their website at: [Website URL].

High-quality Pressure Pot Spray Gun for Professional Painting

Pressure Pot Spray Gun is a versatile tool that has revolutionized the way paint is applied. This remarkable equipment, manufactured by a leading company in the industry, has transformed painting processes across various sectors, including automotive, woodworking, and industrial applications.The Pressure Pot Spray Gun is an essential tool for professionals who seek a reliable, efficient, and cost-effective solution for their painting needs. With its advanced technology and user-friendly design, this equipment has set new standards in the industry, making it the top choice for many professionals and businesses.The Pressure Pot Spray Gun is known for its exceptional performance, durability, and versatility. It is designed to handle a wide range of painting tasks, from small touch-ups to large-scale projects. Whether it’s automotive painting, furniture finishing, or industrial coatings, this equipment delivers superior results with precision and consistency.One of the key features that set the Pressure Pot Spray Gun apart from its competitors is its ability to provide a high-quality finish in a fraction of the time. Its efficient spraying system allows for quick and even coverage, reducing paint wastage and saving valuable time. This not only increases productivity but also minimizes costs, making it an ideal choice for businesses looking to optimize their painting processes.Additionally, the Pressure Pot Spray Gun is equipped with advanced ergonomic features that enhance user comfort and safety. Its lightweight design and well-balanced construction reduce operator fatigue and ensure a comfortable grip for extended use. This makes it an excellent choice for professionals who handle demanding painting tasks on a regular basis.The company behind the Pressure Pot Spray Gun is a renowned leader in the industry, with a reputation for manufacturing high-quality products that meet the needs of diverse professionals and businesses. With decades of experience and a commitment to innovation, the company has consistently delivered cutting-edge solutions that have set new benchmarks in the industry.The company’s dedication to research and development has led to the creation of the Pressure Pot Spray Gun, a game-changing tool that has redefined the standard for quality and performance in the painting industry. By leveraging state-of-the-art technology and industry insights, the company has engineered a product that exceeds expectations and provides unparalleled value to its customers.Moreover, the company’s commitment to quality extends beyond its products to its customer service and support. With a team of knowledgeable and experienced professionals, the company ensures that its customers receive the assistance they need to make the most of their investment. From product selection to after-sales support, the company is dedicated to delivering a seamless experience for its customers.The Pressure Pot Spray Gun has become the go-to choice for professionals and businesses looking to elevate their painting processes. Its exceptional performance, reliability, and cost-effectiveness have made it a game-changer in the industry, setting new standards for efficiency and quality. With the backing of a reputable company that prioritizes innovation and customer satisfaction, the Pressure Pot Spray Gun is poised to continue transforming the industry for years to come.

The Latest Advancements in E-Coating Equipment

E-Coating Equipment Company Advances in Surface Finishing TechnologyInnovative surface finishing technology has become increasingly important in various industries, ranging from automotive and aerospace to consumer goods and electronics. As demand for high-performance and corrosion-resistant coatings continues to rise, companies are constantly seeking advanced solutions to meet these needs. One company at the forefront of this industry is E-Coating Equipment Company, a leading manufacturer of advanced e-coating systems.E-Coating Equipment Company has built a strong reputation for delivering high-quality e-coating solutions that provide superior corrosion resistance, enhanced durability, and aesthetic appeal. With a focus on innovation and customer satisfaction, the company has consistently pushed the boundaries of surface finishing technology, bringing cutting-edge solutions to the market.The company's advanced e-coating equipment utilizes an innovative process known as electrodeposition, which involves applying a paint coating to a metal substrate through the use of an electric current. This process ensures uniform coverage and excellent adhesion, resulting in a smooth and durable finish that effectively protects the metal from corrosion and environmental factors.One of the key strengths of E-Coating Equipment Company lies in its ability to tailor its e-coating solutions to meet the specific requirements of its customers. Whether it's automotive components, industrial machinery, or consumer goods, the company's e-coating equipment is designed to accommodate a wide range of part sizes and geometries, providing a versatile and reliable solution for various applications.Moreover, the company's commitment to sustainability is evident in its e-coating systems, which are designed to minimize environmental impact. By utilizing eco-friendly paint formulations and efficient coating processes, E-Coating Equipment Company helps its customers reduce waste and energy consumption while achieving exceptional coating quality.In addition to its technological advancements, E-Coating Equipment Company also places a strong emphasis on customer support and service. The company's dedicated team of experts works closely with clients to understand their specific coating needs and provide comprehensive technical assistance, ensuring seamless integration of e-coating equipment into their production processes.Looking ahead, E-Coating Equipment Company is poised to continue its leadership in the surface finishing technology industry by further enhancing its e-coating equipment and expanding its global presence. The company is heavily investing in research and development to incorporate the latest technological innovations into its products, driving continuous improvement and staying ahead of market demands.With a strong focus on innovation, quality, and customer satisfaction, E-Coating Equipment Company is well-positioned to meet the evolving needs of industries that rely on high-performance surface finishing solutions. As the demand for superior corrosion resistance and durable coatings continues to grow, the company's advanced e-coating equipment is set to play a pivotal role in shaping the future of surface finishing technology.In summary, E-Coating Equipment Company stands as a testament to the power of innovation and dedication to excellence in the surface finishing industry. With its advanced e-coating systems, the company is poised to continue making significant contributions to the advancement of corrosion-resistant and high-performance coatings across various industries.

Discover the Power of High Pressure Spray Nozzles: Essential Tools for Efficient Cleaning

[Company Name] Introduces Revolutionary High Pressure Spray Nozzle[City, Date] - [Company Name], a leading provider of innovative industrial solutions, is proud to unveil its latest product - a groundbreaking high-pressure spray nozzle. This cutting-edge technology is set to revolutionize various industries by delivering exceptional performance and efficiency.The new high-pressure spray nozzle, which remains unnamed for now, has been meticulously designed and engineered by [Company Name]'s team of experts. With their extensive knowledge and experience, they have developed a nozzle that surpasses existing products in terms of performance, durability, and reliability. This nozzle is set to be a game-changer for businesses in sectors such as manufacturing, agriculture, construction, and more.One of the key features of this advanced spray nozzle is its ability to operate at extremely high pressures, allowing a more efficient and precise delivery of liquids. This versatility makes it suitable for a wide range of applications. Whether it's removing tough grime from industrial equipment, sanitizing large areas, or irrigating crops, this powerful nozzle offers unparalleled performance.Moreover, the high-pressure spray nozzle incorporates cutting-edge materials and innovative design elements to ensure maximum durability. Constructed from high-quality stainless steel, it is built to withstand rigorous use in demanding environments. This longevity not only ensures a more cost-effective solution for businesses but also contributes to a more sustainable approach by reducing waste through longer-lasting equipment.In addition to its exceptional performance and durability, the yet-to-be-named nozzle boasts advanced safety features. With a focus on worker protection and accident prevention, [Company Name] has developed a nozzle that prioritizes user safety without compromising on efficiency. This unique blend of safety and performance sets this spray nozzle apart from its competitors.To provide unmatched convenience, the high-pressure spray nozzle is also compatible with various attachments and extensions. This flexibility allows users to customize the nozzle to suit their specific needs, making it a versatile tool for diverse industries. Businesses can optimize their operations and achieve higher levels of productivity by leveraging the adaptability of this nozzle."Our team at [Company Name] is thrilled to introduce this groundbreaking high-pressure spray nozzle to the market," said [Spokesperson's Name], spokesperson for [Company Name]. "We have poured our expertise and passion into developing a product that will revolutionize various industries. With its advanced features and unparalleled performance, this nozzle is sure to become an essential tool for businesses worldwide."[Company Name] has a proven track record of delivering innovative solutions that meet the evolving needs of different industries. With the introduction of this revolutionary high-pressure spray nozzle, they continue to push boundaries and provide industry-leading solutions to their clients.As of now, the new high-pressure spray nozzle is available for pre-order exclusively through [Company Name]'s website. Customers can visit the website to learn more about the product, its features, and place their pre-orders, securing their access to this groundbreaking technology.About [Company Name]:[Company Name] is a renowned provider of industrial solutions, specializing in delivering innovative products to businesses across various sectors. With a commitment to excellence, they continuously strive to develop cutting-edge technologies that enhance productivity, efficiency, and safety. Their extensive expertise, combined with a customer-centric approach, has made them a trusted name in the industry.For media inquiries, please contact:[Contact Person Name][Contact Person Position][Company Name][Phone Number][Email Address][Website URL]

Top 5 Tips for Improving Your Auto Coating Line

Auto Coating Line, a leading provider of advanced coating solutions for the automotive industry, is pleased to announce the launch of its new state-of-the-art coating line. This innovative technology will revolutionize the way cars are coated, offering superior protection and a flawless finish.The new coating line is the result of years of research and development, leveraging the latest advancements in coating technology. It is designed to meet the growing demand for high-quality, durable coatings that can withstand the harsh conditions of everyday driving while also providing a luxurious and sleek appearance.Auto Coating Line has a long history of providing cutting-edge solutions for automotive coating needs. With a focus on innovation and quality, the company has become a trusted partner for some of the world's leading automotive manufacturers. With the launch of the new coating line, Auto Coating Line is further solidifying its position as a pioneer in the industry.The new coating line features a variety of advanced technologies, including advanced application systems, precision control systems, and environmentally friendly coating formulations. These technologies work together to deliver a superior coating that provides exceptional protection against scratches, UV rays, and environmental pollutants. Additionally, the line is designed to be highly efficient, reducing waste and energy consumption while increasing productivity."We are thrilled to introduce our new coating line to the market," said John Smith, CEO of Auto Coating Line. "We have worked tirelessly to develop a system that not only meets the demanding requirements of the automotive industry but also sets a new standard for excellence. With this new line, we are confident that we will exceed the expectations of our customers and provide them with a coating solution that is second to none."In addition to the advanced technology, Auto Coating Line is also committed to sustainability and environmental responsibility. The new coating line utilizes low-VOC (volatile organic compound) formulations and is designed to minimize waste and emissions. This commitment to sustainability aligns with the company's overall mission to create coatings that are not only high-performing but also environmentally friendly."We understand the importance of protecting the environment, and we have made it a priority to integrate sustainable practices into our operations," said Smith. "With our new coating line, we are not only offering superior performance but also doing our part to minimize our impact on the environment."Auto Coating Line's new coating line is set to be a game-changer in the automotive industry, providing a solution that is both technologically advanced and environmentally responsible. The company is confident that the new line will help its customers stay ahead of the competition and continue to deliver high-quality, reliable vehicles to consumers.As the automotive industry continues to evolve, the demand for advanced coating solutions will only continue to grow. With its new state-of-the-art coating line, Auto Coating Line is well-positioned to meet these demands and push the boundaries of what is possible in automotive coatings. The company's dedication to innovation, quality, and sustainability makes it a valuable partner for automotive manufacturers looking to elevate their products and exceed customer expectations.About Auto Coating Line:With a focus on innovation and quality, Auto Coating Line is a leading provider of advanced coating solutions for the automotive industry. The company is dedicated to pushing the boundaries of what is possible in automotive coatings, with a focus on performance, reliability, and environmental responsibility. Auto Coating Line is committed to providing its customers with cutting-edge solutions that meet the demanding requirements of the industry while also minimizing its impact on the environment.