Ultimate Guide to Inverted Power and Free Conveyors - Everything You Need to Know

By:Admin

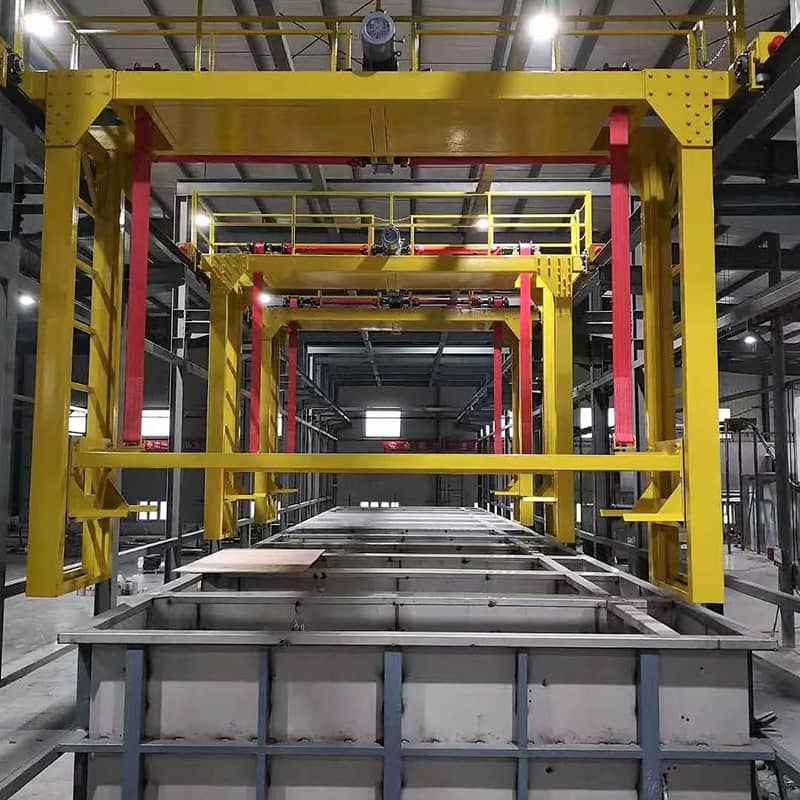

The manufacturing industry is constantly evolving, with new technologies and innovations continuously shaping the way products are produced. One such innovation that is making waves in the industry is the Inverted Power And Free Conveyor system. This revolutionary technology is changing the way materials are transported within manufacturing facilities, improving efficiency and productivity.

The Inverted Power And Free Conveyor is a cutting-edge system that allows for the seamless movement of materials and products throughout a manufacturing facility. This conveyor system is unique in that it utilizes a dual-track design, with one track located above the other. This allows for maximum flexibility and efficiency in material handling, as products can be simultaneously transported on both tracks.

One of the key features of the Inverted Power And Free Conveyor is its ability to handle both heavy and lightweight materials with ease. This makes it an ideal solution for a wide range of industries, from automotive to aerospace and beyond. Additionally, the system is designed to minimize the risk of damage to products during transportation, ensuring that items arrive at their destination in perfect condition.

In addition to its exceptional material handling capabilities, the Inverted Power And Free Conveyor also offers significant space-saving benefits. The dual-track design allows for a compact footprint, maximizing the use of available space within a manufacturing facility. This is particularly advantageous for facilities with limited space, as it allows for efficient material transportation without the need for extensive floor space.

Furthermore, the Inverted Power And Free Conveyor is equipped with state-of-the-art control systems, allowing for precise and reliable operation. This ensures that materials are transported with the utmost accuracy and efficiency, minimizing the risk of errors and delays in production. As a result, manufacturers can significantly improve their overall productivity and output, ultimately leading to increased profitability.

The Inverted Power And Free Conveyor is designed and manufactured by {}, a leading company in the field of material handling solutions. With over 50 years of experience in the industry, {} has established a reputation for delivering high-quality, innovative products that meet the diverse needs of its customers.

In addition to the Inverted Power And Free Conveyor, {} offers a comprehensive range of material handling solutions, including overhead conveyors, floor conveyors, and custom-designed systems tailored to specific requirements. The company is known for its commitment to excellence, with a focus on delivering reliable and efficient solutions that drive success for its clients.

The introduction of the Inverted Power And Free Conveyor has been met with enthusiasm and excitement within the manufacturing industry, as companies seek to leverage the benefits of this advanced technology. Manufacturers are increasingly recognizing the potential of the Inverted Power And Free Conveyor to streamline their operations, reduce costs, and improve overall efficiency.

Looking to the future, it is clear that the Inverted Power And Free Conveyor will continue to play a significant role in shaping the landscape of manufacturing. As technology advances and the demands of the industry evolve, this innovative conveyor system will remain at the forefront of material handling solutions, driving progress and innovation for years to come. With its ability to optimize material transportation, maximize space efficiency, and deliver exceptional performance, the Inverted Power And Free Conveyor is undoubtedly a game-changer for the manufacturing industry.

Company News & Blog

Efficient and Versatile Single Nozzle Sprayer - Your Ultimate Choice!

Title: Innovative Single Nozzle Sprayer Revolutionizes Agricultural IrrigationIntroduction:Innovation in the field of agricultural irrigation has always played a crucial role in meeting the challenges faced by farmers worldwide. Addressing the need for efficient, sustainable, and cost-effective irrigation solutions, a renowned company has invented the groundbreaking Single Nozzle Sprayer. This cutting-edge technology is set to revolutionize agricultural practices, serving as a game-changer for farmers globally.Overview of the Single Nozzle Sprayer:The Single Nozzle Sprayer, developed by a leading irrigation solutions provider (please mention the company name), represents a remarkable advancement in precision irrigation systems. With its state-of-the-art design, this innovative sprayer eliminates the hurdles faced by conventional systems, offering farmers numerous advantages and efficiencies.Unparalleled Accuracy and Uniformity:The Single Nozzle Sprayer stands out with its unmatched accuracy and uniformity in water distribution. Its advanced design precisely targets the crop's roots, ensuring optimal water penetration and nutrient absorption. By precisely delivering water with minimal waste, this technology helps farmers conserve resources and reduce costs.Enhanced Efficiency and Productivity:The Single Nozzle Sprayer employs cutting-edge technology that enables precise control over water flow rates and distribution patterns. Such control allows farmers to adapt the irrigation process to specific crop requirements, ensuring uniform watering throughout the field. By avoiding over- or under-irrigation, this sprayer boosts crop health, leading to increased productivity and higher yields.Saving Water and Resources:Water scarcity is a global concern, making efficient water management an imperative for sustainable agriculture. The Single Nozzle Sprayer incorporates sophisticated features that significantly reduce water consumption. With reduced run-off and improved infiltration, this sprayer optimizes water usage, minimizing waste and preserving this invaluable resource.Versatile Application:Designed to accommodate different crop types and field configurations, the Single Nozzle Sprayer offers versatility in its application. Farmers can easily adjust the nozzle settings, ensuring the sprayer's compatibility with a wide range of crops, including row crops, orchards, vineyards, and more. This flexibility allows farmers to leverage the benefits of the technology across various agricultural sectors.Integration with Smart Farming Techniques:The Single Nozzle Sprayer integrates seamlessly with modern smart farming techniques, leveraging the power of data and automation to maximize efficiency. Equipped with sensors and connectivity features, the sprayer can be controlled remotely, enabling precise monitoring and adjustment of irrigation schedules. Additionally, it can integrate with weather forecast data and soil moisture sensors to optimize irrigation timing and volume.Sustainable Agriculture Advocacy:The Single Nozzle Sprayer aligns perfectly with the growing need for sustainable farming practices. By minimizing the environmental impact through reduced water usage and less chemical runoff, this sprayer promotes eco-friendly methods. Additionally, optimizing irrigation efficiency contributes to conserving energy and preserving soil health, furthering the cause of sustainable agriculture.Market Impact and Reception:The Single Nozzle Sprayer has generated significant interest within the agricultural community, with farmers eagerly awaiting its commercial release. Its potential to increase crop yields, conserve water, and reduce costs has garnered attention from global farming organizations and governmental bodies. Experts anticipate that the widespread adoption of this sprayer will lead to significant advancements in agricultural productivity and sustainability.Conclusion:The revolutionary Single Nozzle Sprayer represents a remarkable leap forward in agricultural irrigation technology. With its precision, efficiency, and sustainability features, this innovation promises to revolutionize farming practices worldwide. By offering farmers increased productivity, water conservation, and reduced expenses, the Single Nozzle Sprayer heralds a new era of precision irrigation, elevating the agricultural industry to greater heights.

Ultimate Guide to Inverted Power and Free Conveyors - Everything You Need to Know

Inverted Power And Free Conveyor Revolutionizing ManufacturingThe manufacturing industry is constantly evolving, with new technologies and innovations continuously shaping the way products are produced. One such innovation that is making waves in the industry is the Inverted Power And Free Conveyor system. This revolutionary technology is changing the way materials are transported within manufacturing facilities, improving efficiency and productivity.The Inverted Power And Free Conveyor is a cutting-edge system that allows for the seamless movement of materials and products throughout a manufacturing facility. This conveyor system is unique in that it utilizes a dual-track design, with one track located above the other. This allows for maximum flexibility and efficiency in material handling, as products can be simultaneously transported on both tracks.One of the key features of the Inverted Power And Free Conveyor is its ability to handle both heavy and lightweight materials with ease. This makes it an ideal solution for a wide range of industries, from automotive to aerospace and beyond. Additionally, the system is designed to minimize the risk of damage to products during transportation, ensuring that items arrive at their destination in perfect condition.In addition to its exceptional material handling capabilities, the Inverted Power And Free Conveyor also offers significant space-saving benefits. The dual-track design allows for a compact footprint, maximizing the use of available space within a manufacturing facility. This is particularly advantageous for facilities with limited space, as it allows for efficient material transportation without the need for extensive floor space.Furthermore, the Inverted Power And Free Conveyor is equipped with state-of-the-art control systems, allowing for precise and reliable operation. This ensures that materials are transported with the utmost accuracy and efficiency, minimizing the risk of errors and delays in production. As a result, manufacturers can significantly improve their overall productivity and output, ultimately leading to increased profitability.The Inverted Power And Free Conveyor is designed and manufactured by {}, a leading company in the field of material handling solutions. With over 50 years of experience in the industry, {} has established a reputation for delivering high-quality, innovative products that meet the diverse needs of its customers.In addition to the Inverted Power And Free Conveyor, {} offers a comprehensive range of material handling solutions, including overhead conveyors, floor conveyors, and custom-designed systems tailored to specific requirements. The company is known for its commitment to excellence, with a focus on delivering reliable and efficient solutions that drive success for its clients.The introduction of the Inverted Power And Free Conveyor has been met with enthusiasm and excitement within the manufacturing industry, as companies seek to leverage the benefits of this advanced technology. Manufacturers are increasingly recognizing the potential of the Inverted Power And Free Conveyor to streamline their operations, reduce costs, and improve overall efficiency.Looking to the future, it is clear that the Inverted Power And Free Conveyor will continue to play a significant role in shaping the landscape of manufacturing. As technology advances and the demands of the industry evolve, this innovative conveyor system will remain at the forefront of material handling solutions, driving progress and innovation for years to come. With its ability to optimize material transportation, maximize space efficiency, and deliver exceptional performance, the Inverted Power And Free Conveyor is undoubtedly a game-changer for the manufacturing industry.

Discover the Secrets to Enhancing Your Space with Decorative Paint

Decorative Paint Shop: A One-Stop Solution for Your Paint NeedsDecorative Paint Shop, a well-known paint store in the industry, offers a wide range of paint products and services. With over 20 years of experience, the company has established itself as a reputable and reliable supplier of paints, coatings, and other related products. From residential to commercial painting projects, Decorative Paint Shop provides a one-stop solution for all your paint needs.The company excels in offering high-quality paint products that meet the specific needs of its customers. Whether it's paints for interior or exterior surfaces, Decorative Paint Shop offers a broad range of finishes, colours, and applications that cater to the diverse needs of their clients. Among their products are interior and exterior paints, primers, varnishes, stains, sealants, and many more. All their products come from top manufacturers in the industry, ensuring the highest quality of the paint they provide.Decorative Paint Shop puts a premium on customer service. Their team of experts offers personalized assistance to customers, from product selection to application techniques. The company's sales staff is knowledgeable, highly trained, and always eager to provide advice and solutions for any painting needs. They listen to their customers' needs and provide tailored solutions according to their requirements.In addition to their paint products, Decorative Paint Shop provides paint services as well. The company offers professional painting services for both residential and commercial clients. They have a team of experienced painters who use top-of-the-line equipment and techniques to deliver the highest quality workmanship. Whether it is a single room or an entire building, the company has the resources and expertise to take on any painting project.Decorative Paint Shop prides itself on the variety of services they offer. From colour matching to spray painting, the company offers a wide range of services to meet any paint needs. They provide services such as in-home consultations, colour consultations, professional spray painting, sandblasting, and restoration services. With their extensive range of service offerings, Decorative Paint Shop is a one-stop-shop for any paint project.The company is committed to providing environmentally friendly alternatives to conventional paints. They offer eco-friendly products and services that are ecologically sustainable and safe for both the environment and the customers. Their eco-friendly paints and coatings are low in toxic chemicals and release minimal harmful emissions, making them suitable for both residential and commercial spaces.Decorative Paint Shop has always been committed to providing customers with the best value for their money. Their products and services are competitively priced, making them accessible to a wide range of customers. The company also offers various promotions and discounts throughout the year, providing customers with even more value for their money.In summary, Decorative Paint Shop is a leading paint supplier that provides a wide range of paint products and services. They offer high-quality products, professional painting services, eco-friendly alternatives, and excellent customer service. With over 20 years of experience, the company has established itself as a reputable and reliable partner for any painting project. Their one-stop solution for your paint needs ensures that customers can get all their requirements met under one roof. Contact Decorative Paint Shop today and let them help you transform your space with high-quality paint products and professional services.

Top 5 Ovens for Enhanced Baking at Home

article about a new electric oven on the market that offers enhanced features and advanced technology.In the world of home cooking, there is nothing more important than a functional, reliable and high-quality oven. This is why there is great anticipation among culinary enthusiasts and home cooks for the new electric oven that has just been released onto the market.The oven, designed with top-of-the-line technology and features, promises to revolutionize home cooking and bring greater efficiency, ease, and precision to the kitchen.Some of the incredible features of this new electric oven are its dual-temperature control, temperature memory function, and advanced convection technology. This oven is designed to cook food quickly and evenly, even during the most challenging culinary tasks.The dual-temperature control feature allows users to program two separate temperatures for cooking, which is ideal for dishes that require both high and low temperatures. The temperature memory function means that users don't have to start over completely when there is a power cut or if the oven is turned off accidently.The oven also boasts advanced convection technology. This means that hot air circulates evenly around the food you're cooking, which makes sure it's cooked evenly from all directions. This technology is perfect for baking different types of foods and cooking them to perfection every time.The oven is designed with several easy-to-use features, such as an LED touch screen display and a built-in timer. The touch screen display allows you to choose the temperature settings, time settings, and cooking options. This means you can choose how you want your food cooked without any complicated settings.The built-in timer is another excellent feature of the new electric oven. You can easily set the timer to the exact time you need, and it will alert you when your food is ready. This means you can cook multiple dishes at the same time, and you will always know when each one is ready to be served.This oven is more energy-efficient compared to traditional ovens, making it an eco-friendly alternative that saves families on their electric bills.In addition to all these incredible features, this new electric oven is also stunningly beautiful. The oven's design conveys a sense of modern elegance, with a touch of a classic elements, which is perfect for any modern kitchen.In summary, this new electric oven offers a unique experience of superior cooking accuracy, eco-friendly features, and an appealing design that enhance the overall cooking experience. It is a great investment for any home cook.

Ultimate Guide to On-Floor Towline Conveyor Systems: Benefits, Applications, and Cost

Achieving maximum efficiency and productivity on the manufacturing floor is essential for any company looking to stay competitive in today's fast-paced market. With the increasing demand for speed and accuracy in production processes, businesses are constantly seeking innovative solutions to streamline their operations. This is where the On-Floor Towline Conveyor system, provided by a leading material handling solutions company, comes into play.The On-Floor Towline Conveyor system is designed to efficiently transport materials and products throughout a manufacturing facility. This revolutionary system is comprised of a series of connected carts that are pulled along a designated path, providing a seamless flow of materials from one work station to another. By utilizing this automated system, businesses can significantly reduce the need for manual labor, reduce production time, and ultimately improve overall operational efficiency.One of the key features of the On-Floor Towline Conveyor system is its flexibility and adaptability. It can be easily customized to suit the specific requirements of a wide range of industries, including automotive, pharmaceutical, food and beverage, and many others. This adaptability allows businesses to integrate the system into their existing operations without disrupting their workflow, ultimately leading to a smoother transition and faster ROI.In addition to its adaptability, the On-Floor Towline Conveyor system is also known for its reliability and durability. The carts are designed to withstand heavy loads and can be configured to accommodate various types of materials, making it an ideal solution for businesses with diverse production needs. This level of dependability ensures that businesses can rely on the system to consistently deliver the performance they need to meet their production targets.Furthermore, the On-Floor Towline Conveyor system is equipped with advanced control and monitoring capabilities, allowing businesses to have real-time visibility into their material handling processes. This level of insight enables businesses to identify and address any potential bottlenecks or inefficiencies within their operations, ultimately leading to improved productivity and reduced downtime.The company behind the On-Floor Towline Conveyor system has been a leader in the material handling industry for over 50 years. With a strong commitment to innovation and customer satisfaction, the company has continuously evolved its product offerings to address the changing needs of the market. By leveraging their extensive experience and expertise, the company has been able to develop advanced solutions that help businesses optimize their material handling processes and stay competitive in their respective industries.One of the guiding principles of the company is a focus on providing comprehensive support and service to their customers. From the initial planning and design phase to installation and ongoing maintenance, the company works closely with their clients to ensure that the On-Floor Towline Conveyor system is seamlessly integrated into their operations. This level of dedication to customer satisfaction has earned the company a reputation for excellence and reliability within the industry.In conclusion, the On-Floor Towline Conveyor system provided by this leading material handling solutions company represents a game-changing solution for businesses looking to optimize their production processes. With its flexibility, reliability, and advanced capabilities, the system is well-equipped to meet the evolving needs of the modern manufacturing industry. Through their commitment to innovation and customer satisfaction, the company behind the On-Floor Towline Conveyor system continues to set the standard for excellence in material handling solutions.

Discover the Ideal Powder Coating Oven for Wheels in the Latest News Content

Title: Cutting-Edge Powder Coating Oven for Wheels Revolutionizes the Automotive IndustryIntroduction:In a ground-breaking move that is set to revolutionize the automotive industry, a leading company has unveiled its latest innovation - a high-performance powder coating oven designed specifically for wheels. This cutting-edge technology is all set to transform the way wheel components are coated, enhancing their durability, appearance, and overall performance. With an unwavering commitment to excellence and a history of delivering top-notch products, this company is poised to disrupt the market with its state-of-the-art powder coating oven.The Features and Benefits of the Powder Coating Oven:The new powder coating oven boasts an array of features and benefits that position it at the forefront of wheel coating technology. With a focus on precision, efficiency, and cost-effectiveness, this innovative oven provides a wide range of advantages that surpass traditional coating methods.1. Advanced Temperature Control: The oven incorporates cutting-edge temperature control technology, ensuring precise and consistent heat distribution throughout the process. This results in a more even and superior coating quality, significantly reducing the risk of imperfections.2. Customization Options: The oven allows for a broad spectrum of color customization options. Manufacturers and vehicle owners can now choose from an extensive range of hues, finishes, and effects to match their unique preferences and brand identities. This flexibility opens up an entirely new realm of creative possibilities.3. Enhanced Durability: The oven's advanced powder coating process offers exceptional durability, surpassing traditional liquid paint applications. The coating adheres perfectly to the wheels, forming a robust protective layer that is highly resistant to scratches, chips, and corrosion caused by exposure to harsh conditions and road debris.4. Improved Environmental Sustainability: This groundbreaking technology boasts a significant environmental advantage over liquid paint alternatives. Powder coating generates minimal waste, eliminates harmful volatile organic compounds (VOCs), and consumes less energy, making it an eco-friendly choice for both manufacturers and consumers.5. Accelerated Production Process: The oven's high-speed curing capability drastically reduces production time, allowing manufacturers to efficiently meet increasing market demands. With shorter curing cycles and reduced cool-down phases, this cutting-edge technology vastly improves overall productivity.Company's Vision and Commitment to Quality:Driven by a commitment to delivering excellence, innovation, and customer satisfaction, the company behind this groundbreaking powder coating oven has established a strong reputation in the industry. Offering state-of-the-art solutions to meet ever-evolving industry demands, their unwavering commitment to quality has helped them stand out as a leader in the field.With decades of experience, the company's dedicated team of technicians, engineers, and designers have consistently pushed the boundaries of wheel coating technology. By striving for perfection and adopting a customer-centric approach, they have successfully developed this groundbreaking oven, poised to transform the automotive industry.Conclusion:Incorporating cutting-edge technology, high-performance features, and an unwavering commitment to quality, this advanced powder coating oven for wheels is set to revolutionize the automotive industry. With its ability to enhance durability, provide extensive customization, and minimize the environmental impact, this innovative solution is well-positioned to become the go-to choice for manufacturers and vehicle owners alike.As this pioneering oven hits the market, it is expected to drive new possibilities, set industry standards, and reshape traditional coating practices. With its immense potential to transform the way wheels are coated, this innovative technology marks a significant advancement in the automotive sector, delivering superior performance and aesthetics that transcend conventional methods.

Effective Dust Control Spray for Paint Booths

[Company Name], a leading provider of industrial solutions, has recently introduced a new Paint Booth Dust Control Spray that promises to revolutionize the way companies manage dust and particles in their painting operations.The new product, developed by a team of experienced engineers and researchers, is designed to effectively control and trap dust and particles generated during the painting process. With its advanced technology and innovative design, the Paint Booth Dust Control Spray offers a cost-effective and efficient solution for improving air quality and reducing the risk of contamination in paint booths.The Paint Booth Dust Control Spray is a versatile and easy-to-use product that can be applied to various types of surfaces, including walls, floors, and equipment. It works by forming a protective barrier that captures and neutralizes dust particles, preventing them from spreading and accumulating in the painting environment. This not only helps to maintain a clean and safe work area, but also enhances the quality and finish of the painted products.In addition to its dust control capabilities, the Paint Booth Dust Control Spray also offers other benefits, such as reducing maintenance and cleanup efforts, prolonging the lifespan of equipment, and improving overall productivity. With its non-toxic and environmentally friendly formula, the product complies with industry regulations and standards, making it a reliable and sustainable solution for companies in the manufacturing and painting industries."We are excited to introduce our new Paint Booth Dust Control Spray to the market," said [Spokesperson Name], [Title] at [Company Name]. "We understand the challenges that companies face in managing dust and particles in their painting operations, and our goal is to provide them with an effective and easy-to-implement solution. With our innovative product, we aim to help our clients improve their work environment, enhance their production processes, and achieve better results."[Company Name] is dedicated to delivering high-quality industrial solutions that meet the specific needs and requirements of its clients. The company has built a strong reputation for its expertise, reliability, and commitment to excellence, and has established itself as a trusted partner for businesses in various sectors.The introduction of the Paint Booth Dust Control Spray is a testament to [Company Name]'s continuous efforts to innovate and develop products that address the evolving demands of the industry. By leveraging its technical knowledge and industry experience, the company has successfully created a solution that not only solves a common problem, but also delivers tangible benefits to its users.As companies strive to improve their operational efficiency, reduce costs, and meet regulatory standards, the Paint Booth Dust Control Spray offers a valuable tool that contributes to their overall success. With its proven performance and positive impact on the painting process, the product is expected to gain traction and become a go-to solution for businesses seeking to enhance their dust control measures.In conclusion, [Company Name]'s new Paint Booth Dust Control Spray represents a significant advancement in the field of industrial solutions. With its ability to effectively control dust and particles in painting operations, the product is poised to make a positive impact on businesses across various industries, contributing to cleaner, safer, and more productive work environments. As the company continues to innovate and expand its product offerings, it remains committed to helping its clients achieve their goals and succeed in their respective markets.

Top Powder Coating Ovens for Custom Wheels

Powder Coating Oven for Wheels: A Revolution in ManufacturingPowder coating is a process of applying dry paint to a surface. It is an advanced method that produces a hard and durable finish. In the automotive industry, powder coating is typically applied to wheels to provide a high-quality, long-lasting finish that can withstand harsh conditions. However, to achieve a perfect finish, the wheels need to be cured in a powder coating oven. Modern powder coating ovens are designed to provide superior performance while reducing energy consumption and environmental impact. In this article, we will discuss the revolutionary powder coating oven for wheels by one of the leading companies in the industry.{Company Name}, a leading manufacturer of powder coating ovens and equipment, has recently released its latest product for the automotive industry. The powder coating oven for wheels is designed to provide superior curing results while reducing energy consumption and carbon footprint. The {Company Name} powder coating oven is engineered to be highly efficient, reliable, and easy to use.The powder coating oven for wheels has been designed to be versatile to accommodate various wheel sizes and shapes. The oven is equipped with a unique air-flow system that delivers hot air evenly across all parts of the wheel. This eliminates any hot spots or cold spots that often lead to uneven curing or an inferior finish. The oven can also be customized to fit the specific requirements of the customer.One of the key features of the powder coating oven is its energy-efficient design. The oven uses a combination of gas and electricity to reduce energy consumption significantly. The oven's heat transfer system is optimized to retain heat, which means less energy is required to maintain the desired temperature. The system also uses a regenerative blower to reduce energy consumption further.Another important aspect of the powder coating oven for wheels is its environmental impact. {Company Name} uses advanced technology to minimize the oven's carbon footprint while still providing high-quality curing. The oven is designed to emit low levels of carbon dioxide and carbon monoxide. The oven's combustion system is optimized to reduce nitrous oxide emissions, which are a significant contributor to global warming.The powder coating oven for wheels is also designed to be user-friendly and easy to operate. The oven features a touch-screen control system that allows the operator to program and monitor the curing cycle. The oven's software is designed to be user-friendly, and it provides step-by-step instructions to guide the operator through the curing process. The oven's temperature and timer can be adjusted quickly and easily for customized curing cycles.The powder coating oven for wheels is an excellent addition to any automotive manufacturing facility. The oven is engineered to provide high-quality curing results while reducing energy consumption and environmental impact. The oven's versatility and user-friendly features make it an ideal choice for custom or high-volume production. The powder coating oven has been tested rigorously to meet or exceed industry standards for quality and safety.{Company Name} is a distinguished leader in the manufacturing of powder coating ovens and equipment. The company's innovative approach to technology has revolutionized the powder coating industry. The company's success can be attributed to its commitment to producing high-quality products that meet the evolving needs of its customers. The company's powder coating oven for wheels is a testament to its dedication to excellence.In conclusion, the powder coating oven for wheels by {Company Name} is a new and improved model, engineered to provide a superior finish while minimizing its carbon footprint. It is the perfect solution for automotive manufacturers and custom car shops looking to provide an excellent and long-lasting finish for their wheels. With this powder coating oven for wheels, companies can reduce their energy consumption and environmental impact while enhancing their productivity and profitability. The powder coating oven for wheels is a game-changer, and {Company Name} should be commended for its innovative approach to manufacturing.

Baking Temperature Guide for Powder Coat Finishes

[Company Introduction]Established in 1995, our company has become a leading provider of powder coating services in the industry. With our state-of-the-art facility and a team of experienced professionals, we are committed to delivering high-quality, durable, and attractive powder coated finishes to our clients. We specialize in a wide range of powder coating applications, including automotive parts, household appliances, furniture, industrial machinery, and more. Our dedication to excellence and customer satisfaction has earned us a strong reputation in the market, and we continue to strive for innovation and improvement in our services.[News Content]The process of powder coating involves applying a dry powder to a metal surface, which is then cured under heat to form a durable and protective layer. One crucial factor in the powder coating process is the baking temperature, which plays a significant role in determining the quality and performance of the finished product. As a leading provider of powder coating services, our company understands the importance of the proper baking temperature and its impact on the overall result.In recent news, our company has made significant advancements in optimizing the powder coat baking temperature to achieve superior finish quality and durability. Through extensive research and development, our team of experts has fine-tuned the baking temperature parameters to ensure the best results for various applications. The precise control and management of the baking temperature have led to remarkable improvements in the adhesion, coverage, and overall appearance of the powder coated surfaces.Our company has invested in advanced equipment and technology to monitor and adjust the baking temperature with precision and accuracy. This investment has allowed us to offer our clients enhanced quality and performance in their powder coated products, meeting the highest standards and specifications in the industry. The optimized baking temperature has proven to be a game-changer, setting a new benchmark for excellence in powder coating services.Furthermore, our company is committed to sustainability and environmental responsibility in our operations. By optimizing the baking temperature, we have been able to reduce energy consumption and minimize waste in the powder coating process. This not only benefits the environment but also contributes to cost savings for our clients, making our services more efficient and economical.In addition to the technical advancements, our company has also focused on providing comprehensive support and expertise to our clients in understanding the importance of the baking temperature in the powder coating process. We work closely with our clients to assess their specific needs and requirements, offering tailored solutions and recommendations to achieve the best possible results.As the industry continues to evolve, our company remains at the forefront of innovation and progress in powder coating technology. With the optimized baking temperature and our commitment to excellence, we are confident in our ability to deliver exceptional powder coated finishes that meet and exceed the expectations of our clients.In conclusion, the advancements in optimizing the powder coat baking temperature underscore our company's dedication to delivering superior quality and performance in powder coating services. Through our expertise, innovation, and commitment to excellence, we continue to set new standards in the industry, ensuring that our clients receive the best possible results for their powder coated products.

Innovative Eyelet Nozzle Technology

Clip Eyelet Nozzle Introduces Cutting-Edge Innovation to Improve Efficiency and Precision in ManufacturingClip Eyelet Nozzle is proud to announce the launch of their latest innovation in the field of manufacturing. The new nozzle is designed to improve efficiency and precision in the manufacturing process, making it an essential tool for a wide range of industries.This cutting-edge innovation has been developed by a team of expert engineers and researchers at Clip Eyelet Nozzle, a leading company in the manufacturing industry. With years of experience and a commitment to excellence, the company has established itself as a key player in the market, providing high-quality products and solutions to its clients.The new nozzle is designed to streamline the manufacturing process, making it more efficient and cost-effective. It is equipped with advanced technology that allows for precise control and distribution of materials, resulting in higher quality products and reduced waste. This innovative tool is suitable for a wide range of applications, including automotive, aerospace, electronics, and more.One of the key features of the new nozzle is its ability to deliver consistent and uniform flow, ensuring precise and accurate results every time. This level of precision is crucial in industries where even the smallest deviation can lead to significant issues. By implementing the Clip Eyelet Nozzle, manufacturers can effectively eliminate variability in their processes, leading to higher quality products and increased customer satisfaction.In addition to its precision, the new nozzle also offers a high level of versatility. It can be adapted to different materials and production requirements, making it an ideal solution for a wide range of manufacturing processes. This flexibility allows manufacturers to improve their efficiency while reducing the need for multiple tools, ultimately resulting in cost savings and operational excellence.Furthermore, the Clip Eyelet Nozzle is designed with durability in mind, ensuring a long lifespan and minimal maintenance requirements. This reliability is essential for manufacturers who rely on their equipment to operate smoothly and consistently. By investing in the new nozzle, companies can reduce downtime and increase their overall productivity, ultimately leading to improved profitability and competitiveness in the market.The introduction of the Clip Eyelet Nozzle represents a significant step forward for the manufacturing industry. By leveraging cutting-edge technology and innovation, the company has once again demonstrated its commitment to providing industry-leading solutions to its clients. With a focus on efficiency, precision, and reliability, the new nozzle is set to make a significant impact in the manufacturing sector, helping companies to elevate their processes and achieve superior results.As the global economy continues to evolve, manufacturers are constantly seeking ways to improve their operations and remain competitive in the market. The introduction of the Clip Eyelet Nozzle comes at a crucial time, providing a timely and essential solution to meet the ever-changing demands of the manufacturing industry. With its advanced features and proven performance, the new nozzle is poised to become an indispensable tool for manufacturers around the world.In conclusion, the introduction of the Clip Eyelet Nozzle underscores the company's commitment to innovation and excellence, while also addressing the evolving needs of the manufacturing industry. With its advanced technology, versatility, and durability, the new nozzle is set to revolutionize the way manufacturers operate, leading to improved efficiency, precision, and overall performance. As companies continue to seek ways to enhance their processes and stay ahead of the competition, the Clip Eyelet Nozzle stands out as a game-changing solution that promises to deliver tangible and significant benefits to the manufacturing sector.