Top Benefits of Using a Slat Conveyor in Your Business Operations

By:Admin

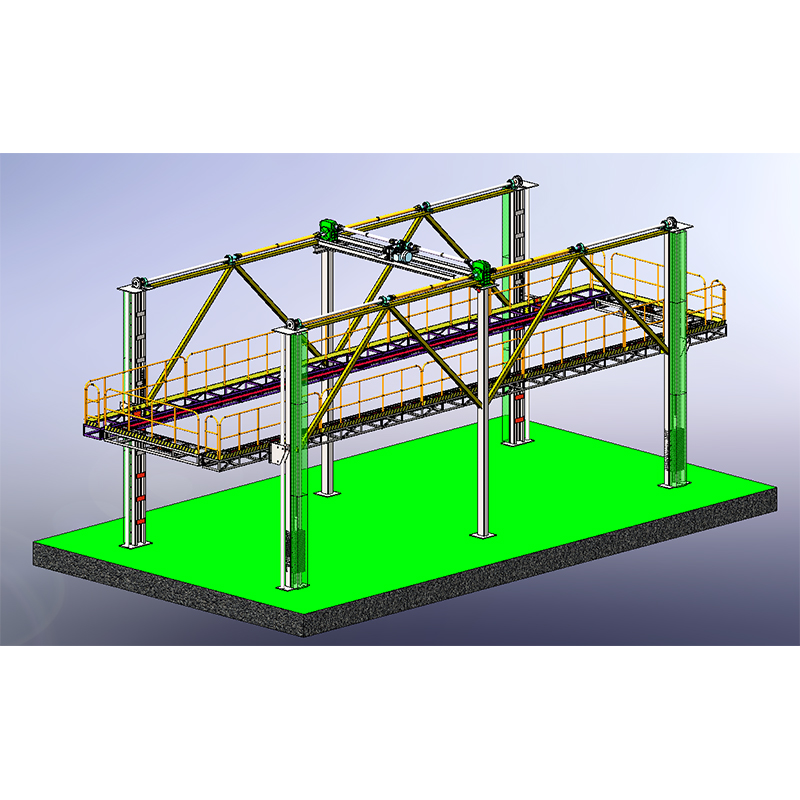

The slat conveyor is a versatile and durable material handling system that is ideal for applications such as manufacturing, distribution, and logistics. It is capable of handling a wide range of products, including boxes, totes, and other heavy items, making it an ideal solution for businesses looking to improve their material handling processes.

One of the key features of the new slat conveyor is its modular design, which allows for easy customization and integration into existing conveyor systems. This modular design also makes it easy to add or remove sections of the conveyor as needed, giving businesses the flexibility to adapt to changing production or distribution requirements.

In addition to its modular design, the slat conveyor also features a robust construction that is capable of withstanding heavy loads and harsh operating conditions. This makes it an ideal solution for businesses with demanding material handling requirements, such as those in the automotive, manufacturing, and aerospace industries.

The slat conveyor is also equipped with a range of safety features to ensure safe and reliable operation. These features include guarding, emergency stops, and safety interlocks, all of which are designed to minimize the risk of accidents and injuries in the workplace.

In addition to its superior performance and safety features, the slat conveyor also offers a number of operational benefits. Its low maintenance requirements and energy-efficient design help to reduce operating costs, while its smooth and quiet operation ensures minimal disruption to the work environment.

"We are excited to introduce our new slat conveyor to the market," said a spokesperson for {Company Name}. "With its superior performance, durability, and versatility, we believe that it will be a valuable addition to our customers' material handling operations."

{Company Name} has established itself as a trusted provider of material handling solutions, with a strong reputation for delivering high-quality products and excellent customer service. The introduction of the new slat conveyor further solidifies the company's commitment to meeting the evolving needs of its customers and providing innovative solutions for their material handling challenges.

The new slat conveyor is now available for purchase and can be customized to meet the specific requirements of different industries and applications. {Company Name} also offers a range of support services, including installation, training, and ongoing maintenance, to ensure that customers get the most out of their material handling investment.

With its advanced design, reliable performance, and operational benefits, the new slat conveyor from {Company Name} is set to make a significant impact on the material handling industry. Businesses looking to improve their efficiency, productivity, and safety in material handling can now turn to {Company Name} for a trusted solution.

Company News & Blog

China's Top Spray Nozzle Manufacturers and Suppliers with Competitive Prices - Wholesale Prices Available

CYCO & CHANGYUAN SPRAYING: Leading the Way in Providing High-Quality Spray NozzlesSpray nozzles play a significant role in the efficient and effective distribution of fluids, gases, and other substances for various industrial applications. From liquid spraying applications to air humidification systems, the proper spray nozzle selection is critical to ensure smooth and efficient operation of equipment.Since 2008, CYCO & CHANGYUAN SPRAYING has been providing high-quality spray nozzles to customers worldwide, catering to various industries such as industrial, agricultural, environmental, and more. With over a decade of experience in the industry, the company has become a leading global manufacturer and supplier of spray nozzles, catering to various industrial applications.What sets CYCO & CHANGYUAN SPRAYING apart from other spray nozzle manufacturers is the company's commitment to quality and innovation. The company employs advanced production techniques and uses high-quality raw materials to manufacture its spray nozzles, ensuring their products are safe, reliable, and long-lasting.The company offers a wide range of spray nozzles, including solid cone spray nozzles, hollow cone nozzles, fire spray nozzles, oil spray nozzles, flat jet spray nozzles, and many others. The spray nozzles are available in different materials, including stainless steel, plastic, and brass, among others.CYCO & CHANGYUAN SPRAYING understands that no two customers' requirements are the same, which is why their spray nozzles are available in various sizes, shapes, and configurations. To cater to their customers' unique requirements, the company also provides customized spray nozzle solutions to meet their specific needs.The company's dedication to customer satisfaction is evident in their commitment to providing top-notch customer service. They prioritize their customers' needs and respond to inquiries promptly, providing necessary support before and after purchase. In addition, customers can choose from various shipping options to get their orders delivered quickly and efficiently.With over a decade of experience in the industry, CYCO & CHANGYUAN SPRAYING's products have received high praise from customers worldwide. The company's spray nozzles have been widely used in various industries, including automotive, chemical, electronics, food processing, and more.In conclusion, CYCO & CHANGYUAN SPRAYING's dedication to quality, innovation, and customer satisfaction has earned them a reputation as a leading global manufacturer and supplier of spray nozzles. Their commitment to providing high-quality spray nozzles, fast and reliable service, and customized solutions has helped them stand out in a highly competitive market. As the company continues to grow, they will undoubtedly maintain their position as a leading provider of spray nozzle solutions for numerous industrial applications.

Ultimate Guide to Oven Powder Coating Systems

Oven Powder Coating System - Revolutionizing the Coating IndustryThe coating industry has seen a significant shift towards more efficient and environmentally friendly processes in recent years. As companies strive to reduce their carbon footprint and waste, new technologies have emerged to meet these demands. One such innovation is the Oven Powder Coating System, a cutting-edge solution that is revolutionizing the way coatings are applied to various materials.This innovative system, developed by a leading industrial equipment manufacturer, has quickly gained recognition for its ability to deliver superior coating results while also reducing energy consumption and waste. The technology is designed to provide a more sustainable and cost-effective alternative to traditional coating methods, making it an attractive option for companies looking to improve their environmental impact and bottom line.The Oven Powder Coating System operates on the principle of electrostatic attraction, where charged powder particles are attracted to a grounded surface. The powder is then cured in a specialized oven, creating a durable and high-quality finish. This process eliminates the need for harmful solvents and reduces the release of volatile organic compounds (VOCs), making it an eco-friendly choice for coating applications.In addition to its environmental benefits, the Oven Powder Coating System also offers significant improvements in efficiency and productivity. The system's automated features and precision controls ensure consistent and uniform coating application, reducing the likelihood of defects and rework. This results in higher throughput and lower costs for manufacturers, ultimately leading to a more competitive and sustainable business model.Furthermore, the system's versatility allows for a wide range of applications across various industries, including automotive, aerospace, furniture, and architectural components. Its ability to coat complex geometries and produce a wide array of colors and textures makes it a valuable tool for companies seeking to differentiate their products in the market.One of the key features of the Oven Powder Coating System is its ease of use and low maintenance requirements. The system is designed to be user-friendly, with intuitive controls and minimal downtime for cleaning and maintenance. This means that operators can focus on producing high-quality coated products without the hassle of complicated equipment and lengthy maintenance procedures.As a leading industrial equipment manufacturer, our company is committed to providing innovative solutions that meet the evolving needs of the coating industry. With a strong focus on research and development, we have invested significant resources into the advancement of sustainable and efficient technologies, including the Oven Powder Coating System.Our dedication to environmental sustainability and customer satisfaction has driven us to create a system that not only enhances the performance and quality of coated products but also minimizes the environmental impact of the coating process. The Oven Powder Coating System is a testament to our commitment to driving positive change in the industry and empowering our customers to achieve their sustainability goals.In conclusion, the Oven Powder Coating System represents a significant advancement in the coating industry, offering a more sustainable, efficient, and versatile solution for manufacturers. With its ability to deliver high-quality coatings, reduce waste, and improve productivity, this innovative system is poised to revolutionize the way coatings are applied across various industries. As a leading industrial equipment manufacturer, our company is proud to be at the forefront of this exciting new era in coating technology, and we look forward to continuing to drive innovation and sustainability in the industry.

Innovative Infrared Radiation Curing Technology for Powder Coating

Infrared Powder Coating: Innovation in Powder Coating TechnologyInfrared radiation curing powder coating technology is a game-changer in the world of industrial finishing. This revolutionary technique speeds up the curing process, reduces energy consumption and costs, and improves product quality and durability. In this blog, we’ll explore how infrared powder coating works, its benefits and applications, and its impact on the future of the powder coating industry.What is Infrared Powder Coating?Infrared powder coating is a process that uses infrared radiation to cure powder coating materials. Unlike traditional oven curing methods that require high temperatures and long baking times, infrared curing heats up the coating materials directly, resulting in faster and more efficient curing. Infrared radiation has a shorter wavelength and higher energy compared to traditional heating methods, such as convection or conduction, allowing it to penetrate the coating materials more deeply and evenly. This makes infrared powder coating ideal for complex shapes, large volumes, and sensitive products that require careful handling.Benefits of Infrared Powder CoatingThere are numerous advantages to using infrared powder coating, from improved productivity and reduced costs to enhanced quality and durability. Some of the key benefits of infrared powder coating include:1. Faster Curing Times: Infrared radiation quickly heats up the coating materials, which can reduce curing times by up to 75% compared to conventional ovens. This means faster processing times and increased throughput for manufacturers.2. Lower Energy Consumption: Infrared radiation uses less energy and requires lower oven temperatures than traditional heating methods, which can result in significant cost savings and lower carbon emissions.3. Improved Product Quality: Infrared radiation provides a more uniform and consistent heat source, which helps to eliminate defects such as pinholes, orange peel, and fisheyes. This leads to a higher quality finish that is more resistant to fading, chalking, and weathering.4. Enhanced Product Durability: Infrared powder coating creates a dense and uniform coating with excellent adhesion and corrosion resistance. This results in a more durable finish that can withstand harsh environments and heavy use.Applications of Infrared Powder CoatingInfrared powder coating is a versatile technology that can be used in a wide range of industrial applications, from automotive and aerospace to furniture and electronics. Some of the common applications of infrared powder coating are:1. Automotive Parts: Infrared powder coating is commonly used for coating car parts such as wheels, body panels, and frames. The fast curing times and enhanced durability of this technology make it ideal for automotive finishes.2. Metal Furniture: Infrared powder coating provides a durable and attractive finish for metal furniture, such as chairs, tables, and shelves. The technology's ability to handle complex shapes and large volumes is especially useful for mass production of furniture.3. Electronics: Infrared powder coating can be used to coat electronic components such as computer cases, circuit boards, and enclosures. Its uniform and consistent coverage can protect sensitive equipment in harsh environments.4. Aerospace: Infrared powder coating is widely used in the aerospace industry, where its durability, corrosion resistance, and low weight are essential. Its ability to handle large volumes and complex shapes make it a popular choice for aircraft and space vehicles.The Future of Infrared Powder CoatingInfrared powder coating is a rapidly growing technology that will continue to evolve and improve in the future. Innovations in infrared radiation sources, equipment design, and software control systems will enable faster and more precise curing of coating materials. Industry-wide adoption of infrared powder coating is also expected to grow, as more manufacturers recognize the benefits of this technology and seek to improve their production processes and product quality.In ConclusionInfrared powder coating is a game-changing technology that offers faster curing times, lower energy consumption, improved quality, and enhanced durability. Its versatility and flexibility make it ideal for a wide range of industrial applications, from automotive and aerospace to furniture and electronics. As this technology continues to evolve and improve, it will drive innovation and growth in the powder coating industry.

Portable Benchtop Spray Paint Booth for DIY Projects

Introducing a Revolutionary Benchtop Spray Booth for Home and Professional UseThe [brand name removed] company is proud to introduce a new innovative product to their line of professional and DIY tools and equipment - the Benchtop Spray Booth. This state-of-the-art spray booth is designed to provide a safe and efficient solution for spraying paints, varnishes, and other aerosol products in a controlled environment.The Benchtop Spray Booth is perfect for both home and professional use, offering a compact and portable design that can be easily set up on any work surface. It is ideal for a wide range of applications, including model making, crafting, hobby projects, and small-scale automotive and industrial finishing.The company [brand name removed] has been a leading manufacturer and distributor of high-quality tools and equipment for over 20 years. Their commitment to providing innovative and reliable products has earned them a reputation for excellence in the industry. The introduction of the Benchtop Spray Booth is another example of their dedication to meeting the needs of their customers and bringing cutting-edge solutions to the market.Key Features of the Benchtop Spray BoothThe Benchtop Spray Booth offers a range of features that set it apart from traditional spray painting methods. Its compact design makes it easy to set up and use in any workspace, while its powerful ventilation system ensures a safe and clean environment for spraying. The booth is equipped with a built-in fan and filter system, which effectively captures and removes overspray and fumes, preventing them from contaminating the surrounding area.In addition, the spray booth is constructed of durable and easy-to-clean materials, making maintenance and upkeep a breeze. It also comes with adjustable lighting to ensure optimal visibility during the painting process. The booth's design allows for easy access and maneuverability, while its quiet operation minimizes disturbances in the work environment.Versatility and Convenience for DIY Enthusiasts and ProfessionalsThe Benchtop Spray Booth is the ideal solution for individuals and professionals who require a safe and efficient method for spraying paints and coatings. It offers a versatile and convenient option for a wide range of applications, from small-scale woodworking and model making to automotive touch-ups and custom finishes. The booth's portable design allows for easy transportation and setup, making it an invaluable tool for on-the-go projects and mobile workshops.The spray booth's compact size also makes it a perfect addition to any home workshop or garage, providing a dedicated space for painting without the hassle and mess of traditional methods. Its ability to contain overspray and fumes ensures a clean and organized workspace, while its efficient ventilation system promotes a healthier and safer environment for DIY enthusiasts and professionals alike.Continued Commitment to Innovation and QualityThe introduction of the Benchtop Spray Booth reflects [brand name removed]'s ongoing commitment to innovation and quality. The company has a long-standing reputation for producing reliable and high-performance tools and equipment, and the spray booth is no exception. By addressing the needs of their customers and staying at the forefront of technological advancements, [brand name removed] continues to set the standard for excellence in the industry.In summary, the Benchtop Spray Booth is an innovative and versatile solution for home and professional painting applications. Its compact and portable design, along with its powerful ventilation system, make it an invaluable tool for DIY enthusiasts and professionals alike. With its introduction, [brand name removed] affirms its dedication to providing cutting-edge solutions and meeting the evolving needs of their customers.

Professional Jobsite Spray Booth for Efficient and Safe Painting Operations

New Jobsite Spray Booth Offers Portable Solution for On-the-Go Professionals"In today's fast-paced world, professionals in the construction, automotive, and manufacturing industries are constantly on the move, working in a variety of locations and environments. The need for a portable, efficient spray booth solution has never been greater. This is where the new Jobsite Spray Booth, from {}, comes into play.The Jobsite Spray Booth is a revolutionary product that provides a portable and versatile solution for professionals who require a clean and controlled environment for their spray painting and finishing needs. Whether working in a remote construction site, on the side of the road for automotive touch-ups, or in a temporary manufacturing facility, the Jobsite Spray Booth offers a reliable and convenient option for professionals who require a high-quality finish.Developed by {} - a leading provider of innovative solutions for the automotive and industrial sectors - the Jobsite Spray Booth is designed to meet the demands of professionals who require a compact, yet effective, spray booth solution. With its durable construction and easy setup, the Jobsite Spray Booth is the perfect choice for those who need a portable and reliable spray booth that can be set up quickly and easily in any location.The Jobsite Spray Booth is equipped with state-of-the-art filtration and ventilation systems to ensure a clean and safe working environment. This allows professionals to work on their projects with confidence, knowing that they are in compliance with all safety and environmental regulations. In addition, the Jobsite Spray Booth is designed to minimize overspray and ensure a high-quality finish, making it an essential tool for professionals who take pride in their work.One of the key features of the Jobsite Spray Booth is its portability. The booth can be easily transported to different job sites, thanks to its compact design and lightweight construction. This makes it an ideal solution for professionals who need to move from one location to another, without sacrificing the quality of their work. Additionally, the Jobsite Spray Booth can be set up in minutes, allowing professionals to get to work quickly and efficiently.The Jobsite Spray Booth is also designed to be versatile, with customizable options to meet the specific needs of different industries. Whether used for automotive refinishing, construction painting, or industrial finishing, the Jobsite Spray Booth can be tailored to provide the right solution for a wide range of applications. This makes it a valuable asset for professionals who work in diverse industries and require a spray booth that can adapt to their unique requirements.With its focus on portability, efficiency, and versatility, the Jobsite Spray Booth is set to become an indispensable tool for professionals in the construction, automotive, and manufacturing industries. By providing a reliable and convenient solution for spray painting and finishing needs, the Jobsite Spray Booth is poised to revolutionize the way professionals work on-the-go.As the demand for portable and efficient spray booth solutions continues to grow, the Jobsite Spray Booth from {} is well-positioned to meet the needs of professionals who require a high-quality finish, no matter where they are. With its innovative design, durable construction, and customizable options, the Jobsite Spray Booth is the ideal choice for professionals who demand the best in their line of work.

Advanced Skid Conveyance System Optimizes Material Handling

Introducing a Revolutionary Skid Conveyance System Poised to Transform Manufacturing ProcessesIn today's fast-paced manufacturing industry, efficiency and productivity are key factors for success. With the constant need to streamline processes and improve output, companies are always on the lookout for innovative solutions to enhance their operations. This is where the Skid Conveyance System comes into play, offering a groundbreaking solution that is set to revolutionize the way materials are transported and managed within manufacturing facilities.The Skid Conveyance System, developed by a leading industrial technology company, is a state-of-the-art solution designed to meet the demands of modern manufacturing environments. It is capable of moving heavy loads with ease, making it an ideal choice for industries where large and bulky materials need to be transported efficiently. The system's advanced design and robust construction make it durable and reliable, ensuring smooth and uninterrupted operation even in the most demanding production settings.One of the most impressive features of the Skid Conveyance System is its versatility. It is easily customizable to fit the specific needs and requirements of different manufacturing processes. Whether it's transporting raw materials, work-in-progress components, or finished products, this system can be tailored to handle a wide range of materials, making it a truly versatile and adaptable solution for various industrial applications.Furthermore, the Skid Conveyance System is designed with efficiency in mind. Its automated operation and high-speed capabilities help to significantly reduce material handling times, ultimately leading to improved throughput and productivity. This is especially crucial in today's competitive manufacturing landscape, where every second counts and optimizing production processes can make a significant impact on the bottom line.The system's advanced control technology allows for seamless integration with existing manufacturing systems, enabling companies to enhance their overall production efficiency with minimal disruption to their current operations. This means that implementing the Skid Conveyance System does not entail a complete overhaul of existing processes, but rather a seamless integration that brings immediate benefits to the production floor.Moreover, the Skid Conveyance System is designed with safety as a top priority. With various built-in safety features and fail-safe mechanisms, the system ensures that materials are transported securely and workers are protected from potential hazards. This focus on safety not only complies with industry regulations and standards but also provides peace of mind for companies looking to create a safe and secure working environment for their employees.In addition to its impressive capabilities, the Skid Conveyance System is backed by a dedicated team of experts who provide comprehensive support and maintenance services. This ensures that the system operates at peak performance at all times, minimizing downtime and maximizing its lifespan. Furthermore, the company offers ongoing training and technical assistance to ensure that clients are fully proficient in utilizing the system to its fullest potential.Overall, the Skid Conveyance System offers a game-changing solution that has the potential to transform manufacturing processes across a wide range of industries. With its advanced technology, customizable design, and focus on efficiency and safety, this system represents a significant leap forward in material handling and transportation within the manufacturing sector. As companies continue to seek ways to optimize their operations and remain competitive in the global market, the Skid Conveyance System is poised to become an essential tool for those looking to stay ahead of the curve in the ever-evolving manufacturing landscape.

Different Types of Spray Can Nozzles: What You Should Know

Spray Can Nozzle Types: A Look at the Latest Innovations in Aerosol TechnologyAerosol technology has come a long way since its inception, with the development of various types of spray can nozzles that cater to different applications and user preferences. From wide-angle nozzles to fine mist sprays, the market is filled with options designed to meet the specific needs of consumers.One company at the forefront of this innovation is {Company Name}, a leading manufacturer of aerosol cans and dispensing systems. With a focus on providing high-quality products and innovative solutions, they have been at the forefront of developing new and improved spray can nozzle types that offer enhanced performance and user experience.{Company Name} has recently unveiled their latest line of spray can nozzles, showcasing their commitment to staying ahead of the curve in aerosol technology. The new range includes a variety of nozzle types, each designed to deliver precise and consistent spray patterns for different applications.One of the key highlights of {Company Name}'s new spray can nozzles is their wide-angle design, which allows for greater coverage and dispersion of the aerosol product. This type of nozzle is ideal for applications such as painting, automotive detailing, and industrial coatings, where a broad and even spray pattern is essential.In addition to wide-angle nozzles, {Company Name} has also introduced fine mist spray nozzles that are designed to produce a delicate and uniform mist, perfect for applications such as cosmetics, household cleaners, and personal care products. These nozzles are engineered to provide a controlled and gentle spray that ensures efficient coverage without wastage.Another innovative feature of {Company Name}'s new spray can nozzles is their adjustable spray patterns, allowing users to customize the output according to their specific requirements. This gives consumers the flexibility to switch between a concentrated stream and a wider spray, making the nozzles versatile and adaptable to different tasks.Furthermore, {Company Name} has also incorporated ergonomic design elements into their new spray can nozzles, ensuring that users can comfortably handle and operate them for extended periods. This focus on user experience and convenience sets their products apart from traditional spray can nozzles, which are often cumbersome and difficult to control.In terms of sustainability, {Company Name} has also made significant strides with their new spray can nozzles, utilizing eco-friendly materials and manufacturing processes that reduce environmental impact. This aligns with the company's commitment to promoting sustainability and responsible business practices in their operations.Overall, {Company Name} is setting a new standard in aerosol technology with their latest range of spray can nozzles, delivering a blend of performance, convenience, and environmental responsibility. As the demand for efficient and user-friendly aerosol products continues to grow, it is clear that innovative solutions like those provided by {Company Name} will play a pivotal role in shaping the future of the industry.In conclusion, the evolving landscape of aerosol technology is driving companies like {Company Name} to push the boundaries of innovation and deliver cutting-edge solutions to meet the diverse needs of consumers. With their new line of spray can nozzles, {Company Name} is poised to make a significant impact in the market and set a new benchmark for excellence in aerosol dispensing systems.

Spray Booths for Various Applications: Cocoa Butter, Chocolate, Egg Wash, Airbrush Color, Petal Dust

High-Quality Small Powder Curing Ovens from Chinese Manufacturers and Suppliers

A small powdercoating oven is an essential piece of equipment for businesses and DIY enthusiasts who want to achieve long-lasting, high-quality finishes on their metal and plastic projects. These ovens are designed to cure powder coatings by baking them onto the surface of the substrate, creating a durable and attractive finish that resists wear, corrosion, fading, and chipping.At Hangzhou Color Powder Coating Equipment, we offer a range of small powdercoating ovens that are perfect for small-scale projects, such as automotive parts, motorcycle frames, bicycle components, jewelry, and DIY home improvement projects. Our ovens are made with high-quality materials and components, ensuring reliable performance, fast heat up times, and even temperature distribution throughout the curing process.One of the key advantages of using a small powdercoating oven is the ability to achieve a professional-grade finish without the need for expensive spray booths or specialized equipment. With a small oven, you can easily apply powder coatings using a spray gun or electrostatic method, and then cure them in the oven for a few minutes to achieve a hard, durable finish.Another advantage of a small powdercoating oven is its energy efficiency. These ovens are designed to minimize heat loss and maximize heat retention, which means that they consume less energy and require less time to heat up and cool down. This translates into significant cost savings over the long term, especially for DIY enthusiasts who use the oven frequently.When choosing a small powdercoating oven, it's important to consider a few key factors, such as the size of the oven, the type of heating element, the temperature range, and the ease of use. At Hangzhou Color Powder Coating Equipment, we offer a variety of small powdercoating ovens to suit different needs and budgets, from basic models with manual controls to advanced models with programmable digital interfaces.Overall, a small powdercoating oven is an excellent investment for anyone who wants to achieve professional-grade finishes on their metal and plastic projects. With its energy efficiency, durability, and ease of use, this equipment can help you take your DIY hobby or small business to the next level.

Top-Quality Paint Booths for Your Auto Body Needs

: The Importance of Choosing the Right Automotive Painting BoothAs an auto body shop owner, you understand the importance of providing high-quality automotive painting services to your customers. However, achieving flawless paint finishes is not always easy, and it requires not only the skill of your technicians but also the right equipment. In particular, the automotive painting booth is a crucial piece of equipment that can significantly impact the quality of your painting results. In this blog post, we will discuss the importance of choosing the right automotive painting booth and how it can benefit your business.What is an Automotive Painting Booth?An automotive painting booth, also known as a spray booth, is a specialized enclosure designed to contain paint overspray and to provide a controlled environment for the painting process. The booth typically consists of a large structure made of metal or other materials that encloses the vehicle being painted, along with a system of fans, filters, and ventilation ducts. The booth creates a positive pressure, which keeps dust and contaminants out and prevents the escape of overspray. Additionally, it helps maintain an ideal temperature and humidity level for the paint to dry properly and achieve a smooth, even finish.Why the Right Automotive Painting Booth Matters?There are various types of automotive painting booths available on the market, each with its own set of features and specifications. However, not all booths are created equal, and choosing the wrong one can lead to several negative consequences. Here are some reasons why choosing the right automotive painting booth matters:1. Better Quality of Painting ResultsOne of the primary benefits of using a high-quality automotive painting booth is that it can significantly improve the quality of your painting results. A well-designed booth will provide a controlled environment that minimizes the impact of external factors such as dust, humidity, and temperature fluctuations. This, in turn, results in more consistent and uniform finishes that are free of blemishes, runs, or other imperfections.2. Increased Efficiency and ProductivityAnother key advantage of using the right automotive painting booth is that it can increase your efficiency and productivity. A booth that is equipped with advanced features such as a heated air make-up system, adjustable motors, and energy-efficient lighting can help you paint more cars in less time. Moreover, a high-quality booth can reduce the need for costly and time-consuming touch-ups, which can improve your bottom line.3. Compliance with Safety StandardsOperating an auto body shop carries inherent risks, and ensuring the safety of your workers and customers is of paramount importance. Using an automotive painting booth that complies with safety standards such as NFPA 33 or OSHA regulations can help you reduce the risk of fire, explosion, or other hazards. Additionally, a booth that is properly ventilated and equipped with high-quality filters can protect your workers from inhaling dangerous fumes or particulates.4. Enhanced Environmental ResponsibilityAs an automotive painting professional, you have a responsibility to reduce your environmental impact and comply with relevant regulations. Choosing an automotive painting booth that is designed with environmental responsibility in mind can help you achieve these goals. For example, using a booth that is equipped with energy-efficient lighting, low-VOC filters, or a recirculation mode can reduce your energy consumption and waste generation, while also improving your compliance with EPA or other regulations.In conclusion, choosing the right automotive painting booth is crucial for achieving high-quality painting results, improving efficiency and productivity, complying with safety standards, and enhancing environmental responsibility. At Tools USA, we offer a wide range of high-quality, durable, and cost-effective automotive painting booths for every budget and requirement. Contact us today to learn more about our products and services.